Different Systems on a Naval Submarine

This is the fifth part of the series of submarine design. Please read the first four here – Introduction to submarine design, Understanding submarine design, Unique tanks on a submarine, and Understanding structure design of submarine

Among the systems required for the operation of a submarine and completion of its mission, some have a remarkable similarity with those used in surface ships, whereas other systems are very uniquely designed only for the environment a submarine operates in.

It is to be noted that a typical diesel electric submarine would have more than 150 systems in all, some of which are used to cater to the major systems on-board.

This article will throw light on the primary systems used on-board a typical diesel electric submarine.

To list them, the primary systems on a submarine are as follows:

- Propulsion system

- Diving and surfacing system

- Power generation and distribution system

- Compressed air system

- Hydraulic system

- Steering control system

- Air conditioning an ventilation system

- Refrigeration system

- Shafting systems (a subsystem of main propulsion system)

- Water cooling system

- Garbage treatment and ejector plant

- Lube oil system

- Diesel oil system

- Diesel air intake and exhaust system

- Fire-fighting system

- Centralised lubrication system

- Masts and periscopes

- List and trim management system

- Missile and torpedo firing system

- Indication and instrumentation systems

- Power and lighting networking system

- Depth gauging and echo sounding system

- Sound power telephonic system

- Intercom / Internal communication system

- Radar and Sonar systems

- Radiation monitoring system

- Pressure hull insulation system

Propulsion System:

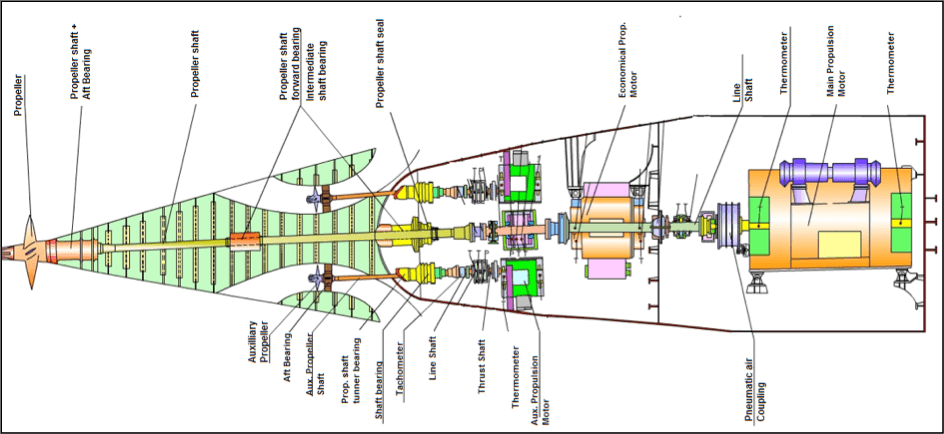

The propulsion system is housed in the aft section of the submarine. The layout of a propulsion plant of a diesel electric submarine is shown in Figure 1, and the main components are then discussed below.

Propeller: Submarines mostly use five bladed propellers with high skew to reduce cavitation and effects of imbalanced thrust forces that act as exciting forces for longitudinal vibration of the shafting system. A larger diameter propeller with low RPM enables higher propulsive efficiency.

Main Electric Propulsion Motor (EPM): The propulsion plant is distributed over two watertight compartments. The main electric propulsion plant is located in the first compartment of the propulsion plant (refer to figure). It is driven by the electric power produced by the batteries. A DC powered motor is always used, as more power losses are observed in AC motors.

- A pneumatic air coupling is used to connect the flywheel of the main propulsion motor with the line shaft leading to the next compartment.

- Thermometers are placed at the forward and aft ends of the EPM to measure the temperature of the fuel oil and the lube oil. Based on these temperatures, the flow rate of oil cooling liquids are constantly adjusted to attain the set value.

Economic Motor / Endurance Motor: In normal cruising and war conditions, the submarine operates on different speed modes of the main propulsion motor. In order to increase the endurance of the submarine, when such a need arises, the submarine needs to economise on the consumption of fuel. In such a scenario, the propeller is driven by the economic motor. The endurance motor is located in the second compartment of the propulsion plant, so that either of the two motors can be operated in case of flooding in one of the compartments.

Duct Propulsion System: Some submarines have an additional ducted propulsion system for added redundancy. Ducted tunnels, one on each- port and starboard side, are freely flooded, and provided with a suction propeller driven by individual auxiliary propulsion motors (port and starboard). The operation of these duct propellers would induce a suction of water from the forward porthole of the tunner, and the water jet is ejected from the aft side of the tunnel, resulting in forward motion of the submarine. Operation of both the ducted propellers simultaneously at different speeds is also used to manoeuvre the submarine in the horizontal direction. This system is used when silent operation is a prime necessity at war-zones, as the acoustic signature of the submarine with its main propulsion plant in use, is considerably higher.

Power Generation and Distribution System:

The primary generators of power in a diesel-electric submarine are the diesel alternators. A typical design would usually have two DA sets, one for port and starboard each, rated so as to serve the following purposes:

- To recharge the lead batteries that are drained after a submerged operation. The power required to charge the batteries is governed by the capacity of the cells, the maximum charging current and top-up current of the batteries. It is because of this, the time required for the batteries to be charge depends on the specification of the batteries, not the diesel alternators. The batteries are not rated based on the maximum speed, but on the basis of single continuous cruising speed.

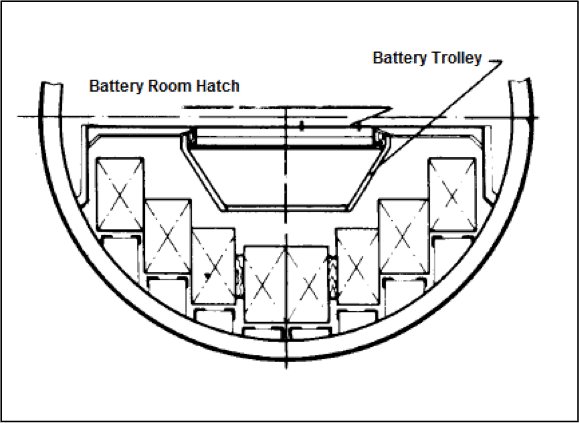

The batteries are placed on stepped floors, and access to the battery compartments is provided by means of a trolley placed just below the battery deck. The operator open the battery hatch and lies flat on the trolley while sliding in in the longitudinal direction to gain access to all the batteries for regular check-ups and maintenance purposes.

- To supply the hotel load in submerged, surface, and snorting conditions. The hotel load of a submarine includes power requirement in the accommodation spaces, cool and cold rooms, weapon systems, sensors, auxiliaries, etc.

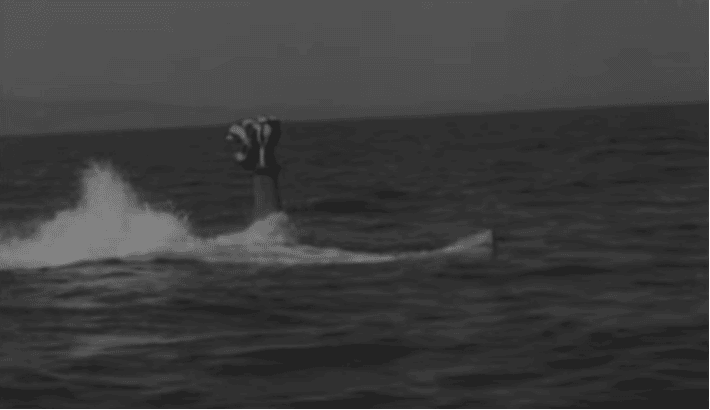

- To propel the submarine in snorting condition. Before we understand this, let’s first look into what snorting is. A diesel electric submarine sometimes requires to run only on diesel generators, that is, in this case the EPM is not powered by the batteries, but by the diesel alternators. This situation usually arises when the batteries are being charged. The submarine then comes up from its dived depth and sails just about 4 to 5 meters below the sea level. It raises its snort mast from the bridge fin, which emerges out of the water surface to allow air intake (which is an important requirement for operation of the diesel generator). This condition is called snorting.

(Source: Youtube – https://www.youtube.com/watch?v=rUHBwz7-7JU)

Now, however, modern diesel electric submarines have air independent propulsion systems installed, where the air can be supplied to the diesel engines from liquefied air stored in air bottles inside the submarine. This enables submerged operation, reducing the risks of detection.

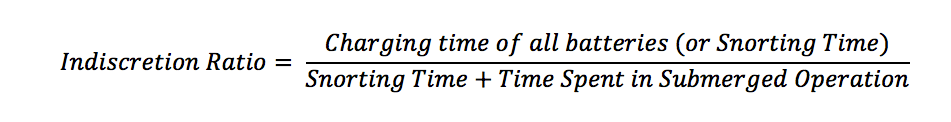

An interesting property of a submarine is its indiscretion ratio, which is defined as the ratio of total snorting time and total time of operation of the submarine. Since the total snorting time is the time taken to charge the batteries, the expression for indiscretion ratio can be written as:

Since designers prefer to reduce the snorting time to reduce chances of detection, a primary focus of choosing the batteries for a submarine is to reduce the indiscretion ratio. Usually modern diesel electric submarines without air independent propulsion have indiscretion ratios ranging from 0.2 to 0.3.

Compressed or High Pressure (HP) Air System:

This is a critical system to a submarine because air in high pressure requires large amount of energy that can be used to obtain maximum output in minimum time. Air is compressed by five stage compressors and stored at 450 bar pressure. It is further reduced to 150 bar and 45 bar pressures for an array of purposes as discussed below:

- For emergency surfacing to save the lives of the crew. The ballast tanks are blowed with 450 bar pressure air to cause an immediate reduction in depth resulting in surfacing.

- It is also used to initiate normal surfacing action of the submarine, but in this cases, 15 bar HP air is used.

- Compressed air is also used to empty compensating and regulating tanks, completely emptying the main ballast tanks when surfaced, starting diesel engines, blowing the bottom valves that have sand clogged in them, whistle actuation, etc.

- Flooding and draining of torpedo tubes and weapon compensating tanks.

Steering Control System:

The steering system of a submarine comprises of control surfaces – a rudder, and two pairs of hydroplanes. One pair of fins is located at the aft, and the other at the bridge fin. The rudder is used to control the yaw motion, and hydroplanes are used to change the trim angles.

The steering systems are hydraulically controlled, and centrally operated from the navigation room steering console. Local control ports are also provided at the fin and the aft, for emergency situations.

Garbage Treatment and Ejector System:

The solid waste generated from usage of stores, and solid human waste are transferred to the garbage treatment system, where ultraviolet and bacterial treatment of the waste decomposes it. The decomposed matter is then stored in unitized decomposable packets, which are shot out of the submarine into the sea by the garbage ejector system. This system is usually located near the longitudinal centre of gravity of the submarine, so that ejection of garbage packets would not cause adverse trimming moments.

Detection System:

A number of detection systems are used on submarines, and the data received, are processed and sent to the weapon control system.

Periscopes: On the development of periscopes, submarines have been enabled with shallow operating capabilities, as in, submarines can be operating at its snorkel depth and raise its periscope above the sea surface to detect the enemy.

There are usually two types of periscopes used –Search Periscope and Attack Periscope. A search periscope is used to cater to the navigational purposes, whereas an attack periscope is specially designed such that the data it received can be used to set inputs for the weapon control system. The search periscope is provided with more optical capabilities than the attack periscope, such that it can be effectively used to retain clear view in twilight and dark. The shape and height of the attack periscope so designed that it is least noticeable when the periscope is raised. It is assisted with a heave control system that keeps the visible height of the periscope constant in spite of heaving motions of the submarine. A periscope is used for the following purposes:

- To observe shipping traffic.

- To observe airborne movement.

- To estimate real-time distances for engagement with enemy.

- To obtain estimated range input for the fire control system.

- To perform celestial navigation in submerged condition.

Radar Systems: A submarine uses radar systems when in surfaced condition or while snorting at periscope depth. Since radar waves cannot propagate in water, the radar antenna is raised through the radar mast, above the water surface. Radar can be used to detect ships and any other surface object upto the range of the horizon.

Similar to periscopes, there are two types of radar systems – Navigational radar and Attack radar. The navigational radar antenna and a rotating signal receiver at its tip are contained in a separate mast that can be hoisted and lowered hydraulically. Do note that when raised, these mast structures are subjected to external hydrostatic pressure, hence all masts on a submarine are pressure resistant structures. The antenna of the attack radar is positioned along with the attack periscope, so that both can be used in tandem. However, since radar is a source of energy, use of radar as a primary detection device may betray the submarine by allowing a detection of its position before it receives the position of the enemy.

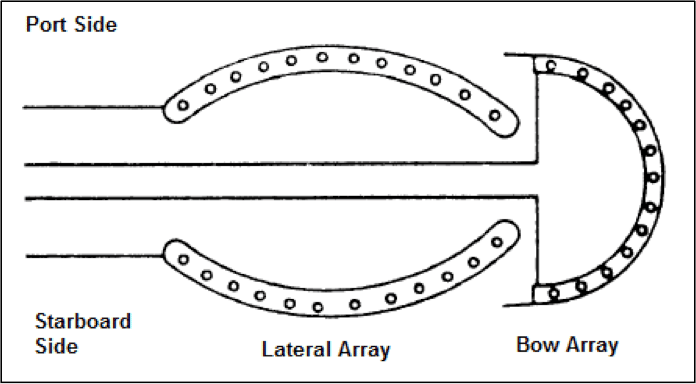

Active Sonar Systems: Sonar systems are used to acoustically detect surface ships and subsurface movement, and they provide more stealth to a submarine when compared to that of a radar system. Active sonar system operates on the same principle as a radar. Rotating sonar transducer arrays are located is located at multiple positions just outside the hull. Their typical layout is shown in the figure below.

These arrays emit sound waves, which if reflected from an underwater obstacle, are received as distinguishable ‘sonar pings’ (watch the video below).The sound waves received is also converted into electronic format to be displayed on the active sonar screen at the sonar console. In order to prevent disturbances, the positioning of arrays is hugely dependent on the shape of the hull, such that they are placed in positions where the flow around the hull is less turbulent, away from the wake of the propeller, and should have sufficient distance from large machinery like diesel generators and EPM.

video of sonar pings:

The disadvantage of active sonars is, the pings emitted by the array can be easily detected by the enemy within the range of the sonar, thus giving away the submarine’s position. Hence, though all naval submarines are equipped with active sonar systems, they do not prefer to use it when stealth is a prime necessity.

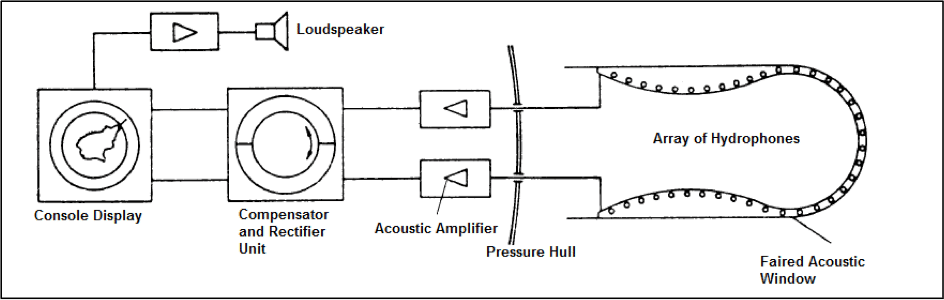

Passive Sonar: This is the most important detection system used in submarines. It consists of an array of sonar hydrophones that only detects external noise and reflects the signal to the sonar control panel in the form of pings.

The hydrophones are arranged in a circular array at the dome of the submarine, in order to avoid directional anomalies. The hydrophones can be arranged in two ways:

- Circular array at the dome, linear array at the sides (lateral array).

- Faired horse-shoe type of arrangement. The arrangement and schematic circuit of a horse-shoe type passive sonar is shown in the figure below.

The range of a passive sonar system depends on the acoustic weather, that is, the salinity, temperature, density of the sea water; the wave conditions, direction of currents, presence of marine life, etc.

The discussion of systems on a submarine is a topic that extends beyond the scope of articles. One can conceptualise the vastness and intricacy of this aspect of submarine design when told that design, development, and integration of these systems on a submarine requires a strong collaboration of mechanical engineers, electrical and electronic engineers, instrumentation specialists, and naval architects. Development of better versions of each of these systems is a continuous process ad depends on how the navy of each country approaches the development of its submarine fleet.

You may also like to read – Pathfinder – An Underwater Submarine that Can Run on Ocean Floor

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

This is a great knowledge for marine engineering week students who are not understand in a poor teachers classes

Thanks a lot Mr. Chakraborty

really i like this site

Dear Sir,

We are New York based military parts supplier and pleased to inquire as follows:

P/N: A090013205

Item: COOLER,FLUID,TRANSMISSION

Q’ty: EA 8

Application:Reduction Gear for the Navy

Destination:South Korea

In this regard,looking forward to receiving your quotation,

Best regards/Richard