Real Life Incidents: Near Miss In Open Water And Good Visibility

A loaded LNG tanker was underway at about a speed of approximately 18 knots in good visibility..

A loaded LNG tanker was underway at about a speed of approximately 18 knots in good visibility..

A general cargo vessel was proceeding in a Traffic Separation Scheme (TSS) at reduced power due to engine problems, making 4.5 knots at dead slow ahead.

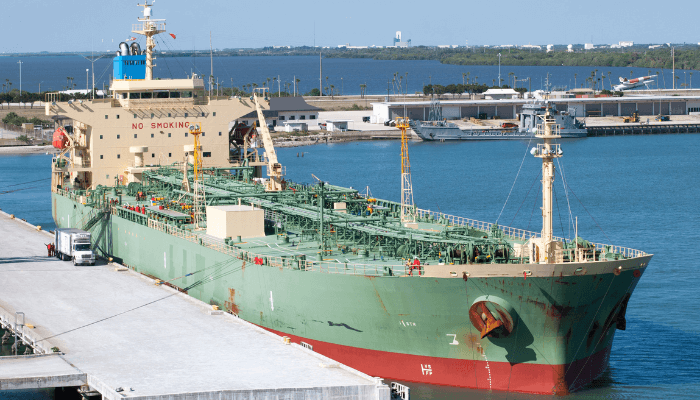

A tanker was approaching a jetty for berthing, While still some distance from the jetty the first heaving line was thrown…

During a Class inspection, the crew were surprised to find that the lower compartment of a crane pedestal contained many sealed paint cans..

The accident investigation revealed that the crewmember had loosened the filter cover without first releasing the system pressure from the vent cock.

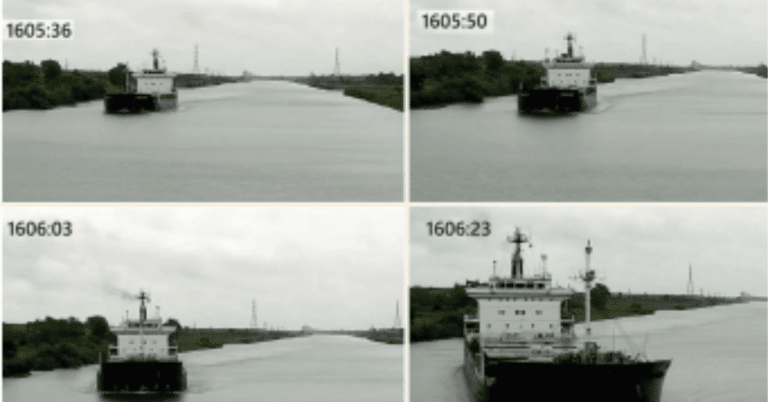

A general cargo vessel under pilotage was up-bound in a canal waterway under reduced speed in anticipation of meeting several down-bound vessels.

An LNG tanker was proceeding in the open sea at a speed of approximately 21 knots in good visibility..

A RoRo ferry had finished loading and was leaving the berth. A strong onshore wind was pushing the ferry against the quay, and two bow thrusters were working at 100% to push the bow off the berth…

A tanker in ballast was departing from a river port, from a position which required a turn of approximately 180°. There was one pilot on board and one tug (the only one available) made fast aft.

"*" indicates required fields