Design Of Asphalt And Bitumen Tankers

With the population booming all around the world, rapid expansion and modernisation of human establishments, and a greater need for efficient connectivity in transportation, there is an increasing demand for roads. Whether it is a developed country or a third world, a rural or an urban area, a populated zone or a remote place, there is an ever-increasing requirement for the construction of roadways.

It is an undisputed fact that for the progress and prosperity of any country, proper and developed land-based connectivity is indispensable. Essentially, for any landmass, there should be free access from any corner to another unless there are some critical or hostile geographical constraints like mountains, dense forests, water bodies, and so on.

However, with advancing time, now even the adverse environments are getting access to people. In most countries, the road network is becoming prevalent across all routes and areas. So, unlike in the olden days, one does not need to worry about travelling from one tip of the country to another.

For the international trade supply chains as well, all forms of freight traded through air or sea need to be further re-transported from the terminals or ports and airports to their respective points as required.

In the US, the current federal fiscal fund allocation for asphalt or road construction is billed at an astronomical budget of nearly 100 billion US dollars.

In contrast, in populous countries like India, the annual government expenditures on major road and highway constructions are in the range of roughly 1,00,000 to 1,50,000 crore Indian rupees. Once again, all these whopping figures are likely to grow ceaselessly.

Hence, it can be said that for any nation, road or asphalt construction is itself a colossal industry and a vital organ of the economy.

A brief on asphalt construction

We must have all witnessed some form of road construction at some point in time or the other. For all practical purposes, most of the roadways are to date constructed out of a petroleum-based, gelatinous, residual or by-product material known as bitumen. This bitumen or asphalt is mostly prepared at very high temperatures of 150 to 180 degrees Celsius and is there in molten forms.

This concentrate has a very thick and sticky nature, and to this stone chips, pellets, gravels, sand, etc., are mixed well in mixers. This heated mixture is sometimes known as the tar or pitch and is laid over the desired areas in hot and semi-liquid form. Thereafter, in the areas where this is laid, a roller is usually run over to engender uniformity everywhere in a process commonly known as paving. After some time, the rolled and hot mixture cools off and hardens to give rise to smooth and solid surfaces for roads.

So, essentially, the bitumen acts as an adhesive for the constituents like stone, gravel, sand, etc. and binds them permanently. These kinds of road constructions are known as asphalt-based or bitumen-based works and have this very, very common blackish appearance.

Many roads are also built out of concrete instead of asphalt, where the former acts as the main binding medium. However, as concrete is more susceptible to damage under very harsh weather conditions, comparatively expensive and less procured than bitumen or asphalt, the latter type remains the most common type of road construction all around the world.

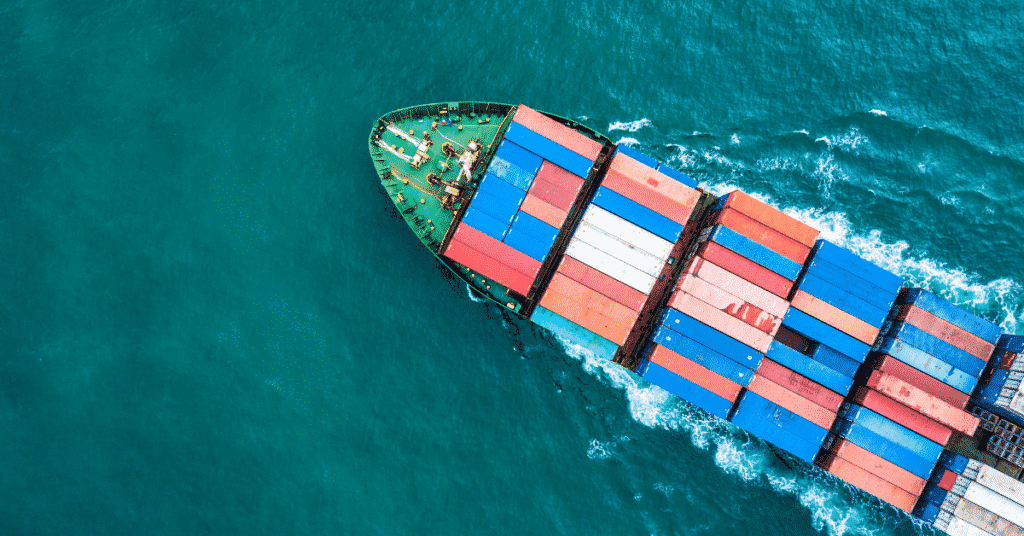

Introduction to Asphalt and Bitumen Carriers

Asphalt and bitumen transport is mostly local or regional as they are common and inexpensive, and every country is more or less self-sufficient in extracting, processing, and producing them. So, instead of intercontinental transport, they are limited to interstate and, at most, international routes. In most cases, asphalt and bitumen transport is limited to point-to-point voyages from one port to another. Asphalt trade through seas accounts for around 0.5-1% of the world’s maritime fleet.

So, asphalt and bitumen tankers are specialised tankers that are designed and constructed to carry asphalt or bitumen contents in the molten form at very high temperatures.

Everything from beginning to end associated with these special-type tankers is related to the temperatures. Asphalt and bitumen are required to be kept at an exceptionally high temperature, otherwise, they tend to pre-harden and be rendered useless.

Now, note that before paving roads, the temperature kept is from 150 to 200 degrees Celsius. This is the temperature that normal high flames can keep their contents in at atmospheric conditions. Moreover, the sticky, semi-liquid, and thick form of asphalt that is ideal for mixing the remaining contents binding them and also allowing for lower time to harden after rolling is best kept at these temperatures.

However, while transporting in ships, the thickness and density of this material need to be further decreased, or in other words, the nature of this asphalt needs to be kept even nearer to liquified form. Why?

The reasons are simple: The closer the contents are to liquefied form, the easier it is to carry as well as load and offload. The asphalt or bitumen tar, if kept in liquefied form, can be loaded as well as unloaded easily with the help of discharge pipes from the vessel, like oil or other forms of liquid cargo.

Furthermore, when the viscosity is lower of the cargo content, there is also a lesser tendency for the cargo to settle at the bottom and hamper not only the loading/offloading operations but also the uniform structural loading of the vessel due to excessive higher loads acting on the bottom areas of the vessel. Also, after offloading, stripping the cargo holds of the residues becomes a very big ordeal for highly viscous type cargo contents.

Hence, for all practical purposes, the cargo contents of an asphalt or bitumen tanker need to be kept at a continuously high temperature in the order of 250 to 300 degrees Celsius.

Let us now look into the core aspects of the design of these tankers next section.

Design of Asphalt and Bitumen Carriers

General

They are mostly small to medium-sized cargo ships with maximum capacities within 30000 dwt tonnage and with cargo designations including all related cargo content like asphalt, bitumen, coal-tar-pitch, creosote, and sometimes fuels for combination-type carriers, but that too within permissible characteristics like low inflammability.

The vessels usually has an elevated main deck in the way of the cargo holds/tanks that is off limits for the crew’s regular usage and has high-grade insulation systems for protecting the cargo from external conditions like freezing as well as preventing massive heat indices from escaping from the spaces to the outside environment.

Similar to other common types of cargo vessels like tankers or bulkers, they have a standard full-form hull type, often with transom sterns. For all practical purposes, all major machinery spaces, like the engine room, are placed at the aft along with the deckhouse above the main deck in the aft.

From a subdivision point of view, the vessels have standard divisions from a damage stability perspective and have well-marked spaces for cargo spaces, ballast, engine spaces, forepeak, and other utilities like freshwater or storage spaces.

Unlike containerships or ferries, they do not have tight schedules for voyages. They mainly have low to medium-speed 2-stroke or 4-stroke diesel engines, usually with a single-screw propulsion system, akin to tankers or bulk carriers. The propulsion system is connected to shaft generators and reduction gearboxes.

Though earlier designs had a single hull, since the contents of asphalt and bitumen tankers are considered hazardous and polluting, double-hull construction is being widely used for modern constructions similar to oil tankers.

Tankage And Heating Systems

Now, let us come to the specific and specialised characteristics of these kinds of carriers.

As mentioned above, bitumen and asphalt carriers need to be transported and continuously maintained at very high temperatures in the range of 200-300 degrees Celsius. Hence, these kinds of vessels are equipped with specialised cargo heating system arrangements.

Most of the heating of cargo is done through the means of thermal oil at very high temperatures. This thermal oil, in turn, is heated by mostly boilers or boiler-like heater electrical systems. Boilers are mostly fired by the Heavy Fuel Oil (HFO) used in main engine propulsion.

So, from the point from where it is being heated, this thermal oil is pumped to the cargo spaces through a special system of piping and is circulated and re-circulated around the cargo tanks through heating coils which are tubular structures transferring the heat to the cargo.

The number of such boilers or heaters depends on the capacity of the vessel. Sometimes, for colder outside temperatures, when rapid heat loss is a crucial problem, a greater number of boilers may be fitted to cater for the higher-level heating of the thermal oil. These heating units have a heating capacity in the range of 1000000 to 2000000 kcal/h rates. In most designs, operating under normal circumstances and external temperatures, one boiler unit should be sufficient to supply heat to the entire rated cargo capacity tonnage on board. The pumps for the same are also of high capacity.

They should run continuously with sufficient backup systems to maintain the temperature of the cargo to desired levels and also, at the same time, prevent settling or coagulation. Often in modern designs, the heat content lost during this circulation and re-circulation process is recovered as ‘waste heat’ and used for other utilities.

After heating, the next major ambit in the design of these carriers is the containment and transport of cargo. Storage of such high-temperature cargo is a very complex matter both in terms of structural as well as the overall vessel risk. Such highly heated cargo leads to tremendous thermal expansion and stresses on the hull that can lead to big-time structural failures.

Moreover, the direct connection of cargo holds to the entire vessel structure can trigger accidental overheating, heat leaks, and fires. So, bitumen and asphalt tankers are fitted with what are known as independent tanks. What are independent tanks? Independent tanks are holds that are not integral to the ship structure. In other words, they are neither permanently welded or is a component of the main hull structure.

These tanks are separately fitted and installed onto the vessel and are supported by plating, pads, bearings, washers, clamps and so on. Sufficient clearance is kept between the tank boundaries and the adjacent shell plating or structure at the sides and bottom to allow for maximum thermal expansion.

The fitting or installation of these tanks is very critical as any defect or error can lead to precarious frictional forces between the tank and the hull structure through the bearings or attached supports, leading to unbalanced loads or forces and, worse, risks like fire outbreaks due to heating.

Most of these tanks are numerous and not very big like LNG or LPG tankers and are collectively known as a single unit called blocks. The types of tanks are often classed as A, B and C. (omitted from discussion in this article).

Another very important aspect of the tanks is the insulation. The very high temperatures pertaining to these holds should be well contained; otherwise, they can be detrimental. On the less serious side, heat loss is also not desirable for the cargo, as already explained above. So, very high-grade insulation is provided to prevent the heat from escaping from the holds.

These insulations are multi-level tested and approved and are present in a specific level of thickness as recommended by the manufacturer as well as classification guidelines. In earlier designs, thick stuffings of wool or fabrics were used, but in almost all modern designs, synthetic and mineral-based insulation is chosen. Any form of cracks or faults in the way of the tanks and their surroundings are repeatedly inspected to prevent any kind of heat loss or leakage.

Outside the insulating layer of the tanks, a separate layer of water and air (space) is also provided to minimise heat transfer in modern designs. Most of the waste heat recovery takes place in between the insulation, heating coils, and tank boundary. The main cargo content is stored in the region known as the core. See the following simple schematic for tankage:

With increasing distance from the core, the temperature/ heat flow also rapidly reduces, as shown in the figure.

For bitumen/asphalt carrier designs, three modes of heat transfer- conduction, convection, and radiation are taken into account.

Most classification norms have special guidelines for these vessels. And along with special strength analysis, thermal analysis for these kinds of tankers is also mandatory to determine thermal stresses and loss of strength due to this highly heated cargo considering the highest level of temperatures and full-load capacity.

As per classification rules, most scantlings, especially in the way of tanks, are kept on the higher side to account for the thermal stresses, increased loads, and also higher fatigue strength values.

You might also like to read-

- The Design Of Modern Ship Masts – A Quick Overview

- What Do You Understand By Prow Of A Ship?

- Understanding Hunting Gear Mechanism Of Ships

- What Is Moulded Depth Of A Ship?

- Understanding The Beam Of A Ship

Do you have info to share with us ? Suggest a correction

About Author

Subhodeep is a Naval Architecture and Ocean Engineering graduate. Interested in the intricacies of marine structures and goal-based design aspects, he is dedicated to sharing and propagation of common technical knowledge within this sector, which, at this very moment, requires a turnabout to flourish back to its old glory.

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.