10 Oily Water Separator (OWS) Maintenance Tips Every Ship Engineer Must Know

Learn about ten important performance enhancing tips, which are often ignored by engineers while operating oily water separator on board ships.

Learn about ten important performance enhancing tips, which are often ignored by engineers while operating oily water separator on board ships.

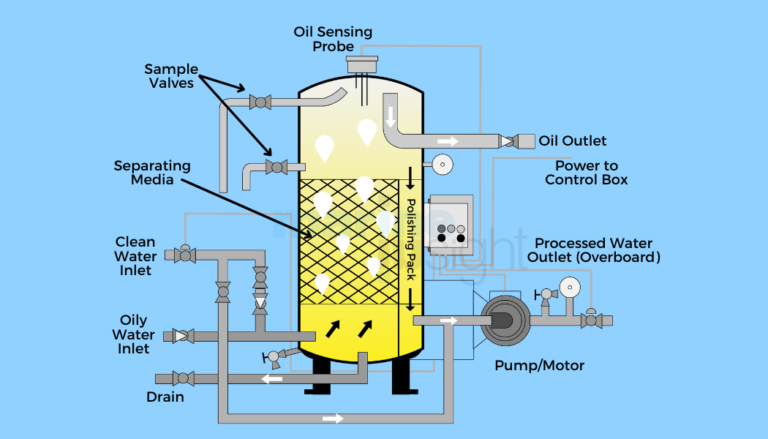

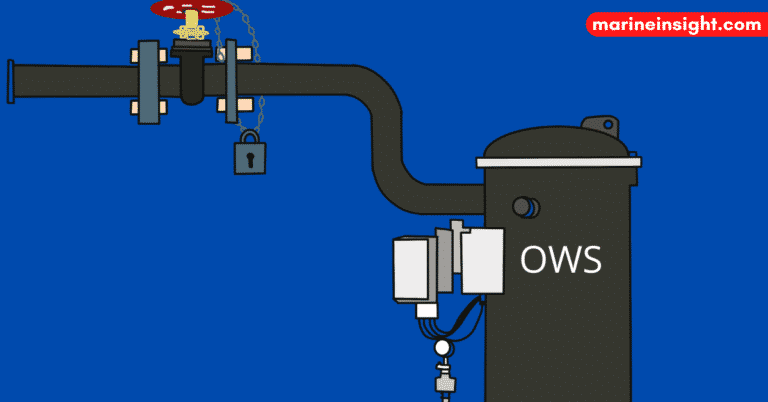

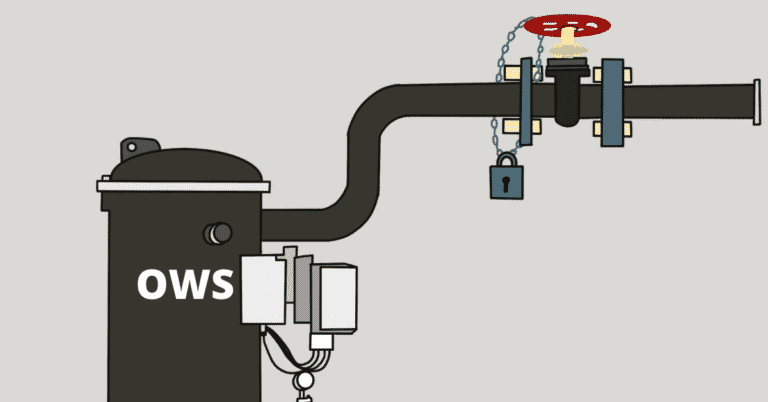

An oily water separator clears the bilge water of oily content to bring it inside the acceptable range to discharge it overboard. An oily water separator is machinery for such importance that it is handled by only the 2nd or chief engineer. (However, the duty engineer might also be asked to operate under supervision)

Optimal performance of Oily water separator on ships depends on a number of factors. Marine Engineers must consider twenty most important aspects mentioned in this article for smooth functioning of the OWS.

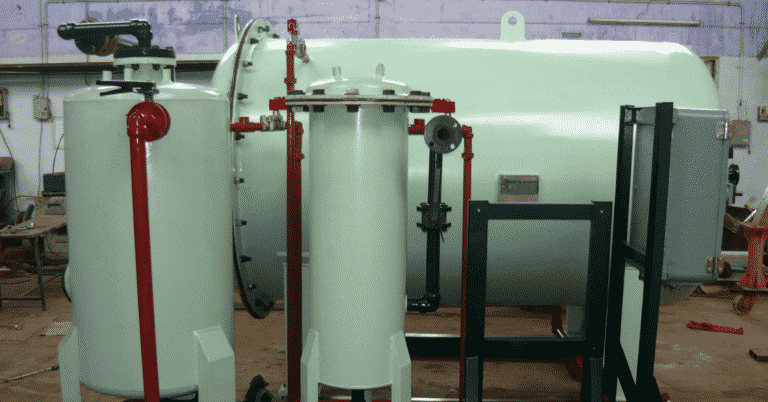

Learn about the construction, working and operation of Oil water separator used on ships, along with the MARPOL and design requirements.

Several parameters affect efficient working of oily water separator on ships. Marine engineers must understand these factors in order to ensure satisfactory operation of oil water separators.

"*" indicates required fields