World’s First Global Maritime Competition

What is a Skeg in a Vessel?

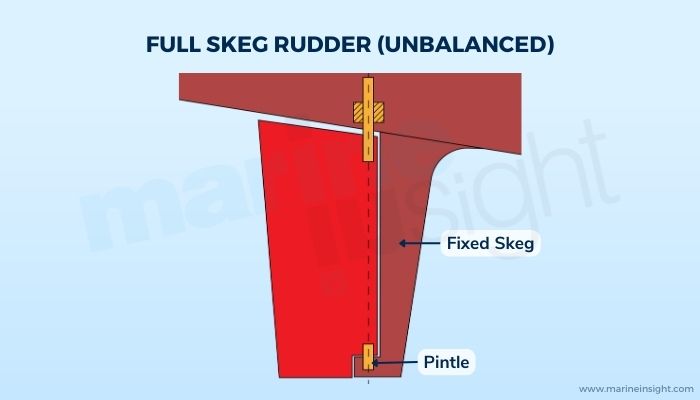

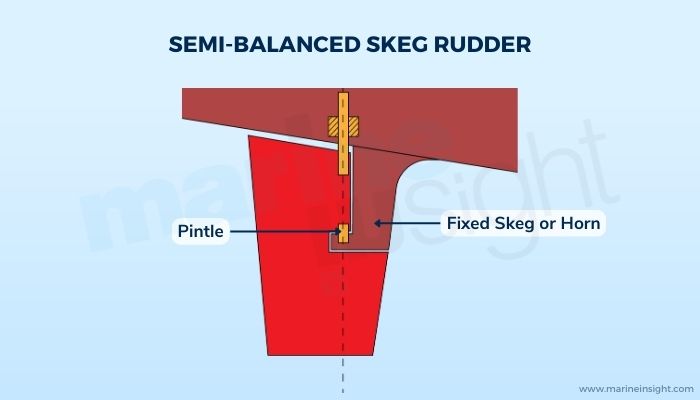

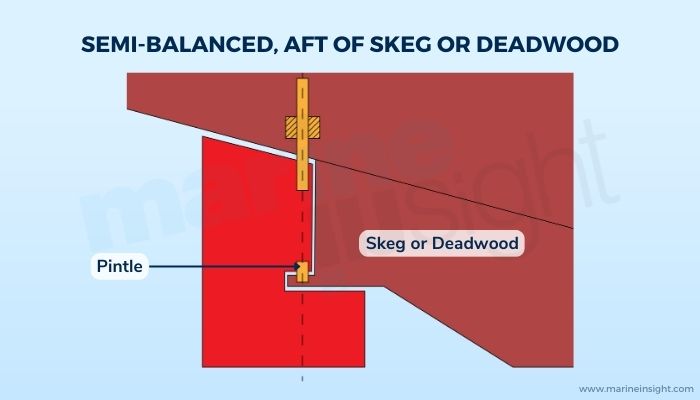

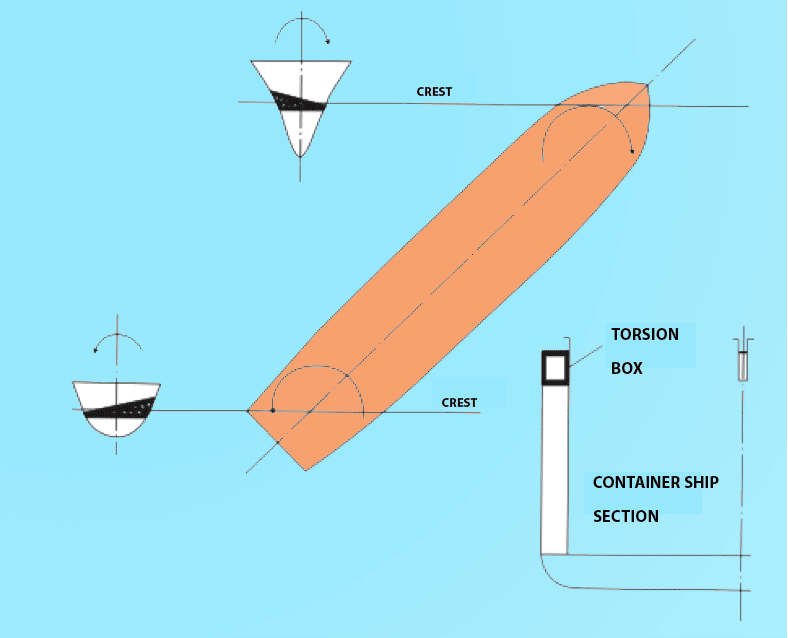

A skeg in a vessel is an important but not a necessary component. A skeg is a vertical tapering projection or an external structural feature at the aft of the vessel, about the centreline, directly attached to the vessel’s bottom shell plating, and mostly, but not necessarily, situated in front of the rudder. As it is not intrinsic to the main hull structure, it can be said as an appendage for all practical purposes.

It may also be defined as the sternward extension of the keel in the exterior of the main hull. (Keel being one of the main internal longitudinal strength members contributing to the global strength of the hull).

Beyond a certain point in the aft (and the front as well), the plating of the hull rises above the baseline as per the hull’s curvature in profile view.

So, the keel plate, which has the highest scantlings in the bottom shell and the central longitudinal bottom girder, rises to the curvature.

So, the skeg, which projects or juts out linearly from the hull’s bottom curvature, can be said to be a member in direct connectivity and linear extension (outside) with the flat shell plating.

In geometry, it is characteristic of a tapering projection (broader at the top and narrower at the bottom) when viewed in a transverse direction and a flat lateral surface when viewed from the sides or in a longitudinal manner. In terms of construction, it is usually composed of two large lateral side flat plates attached longitudinally to the bottom shell and connected in between by a successive series of transverse intermediate plates, which are of the aforementioned tapering shape.

The lower extremity of the skeg is composed of another flat closing plate and connects the two side lateral plates as well as welded to the interspersing transverse plates. Other additional structural and supporting or strengthening members are also present as per requirement. In the front end of the skeg, there is usually a slanted vertical plate that is attached to the bottom shell plating, known as the backplate or faceplate.

The transverse tapering plates are mostly for structurally supporting the skeg. The scantlings of the skeg are usually on the higher side as it is not only an external structure but also is subject to the high modulus of loads and pressures stemming from the waves, currents, as well as potential risks of contact with any type of surface during grounding/accidental damage.

Again, from a geometric point of view, the principal parameters of a skeg can be best defined by A, the face area or the lateral area of the side plates, and t, the mean breadth of any of its cross sections in a transverse view (as sectionally it is tapering and the mean breadth is taken accordingly). For all practical purposes, because of its design and construction, a skeg has a high A/t ratio which means that the area-to-breadth proportion is quite large, as evident, or in other words, a skeg is a very slender structure.

Applications of skeg and some details

1. Hydrodynamics

The most important reason for a skeg is the hydrodynamics. In simple words, the design of the skeg dramatically influences the flow patterns, and this, in turn, affects the dynamics related to the rudder (which is usually in line with the skeg) and the propeller(s). This improved flow pattern reduces drag and resistance. Moreover, the propeller efficiency also increased. Another important aspect under consideration is turbulence. Skegs have been experimentally as well as practically proven to be instrumental in reducing turbulence by tending to transform the turbulent characteristics of the flow to laminar at the stern.

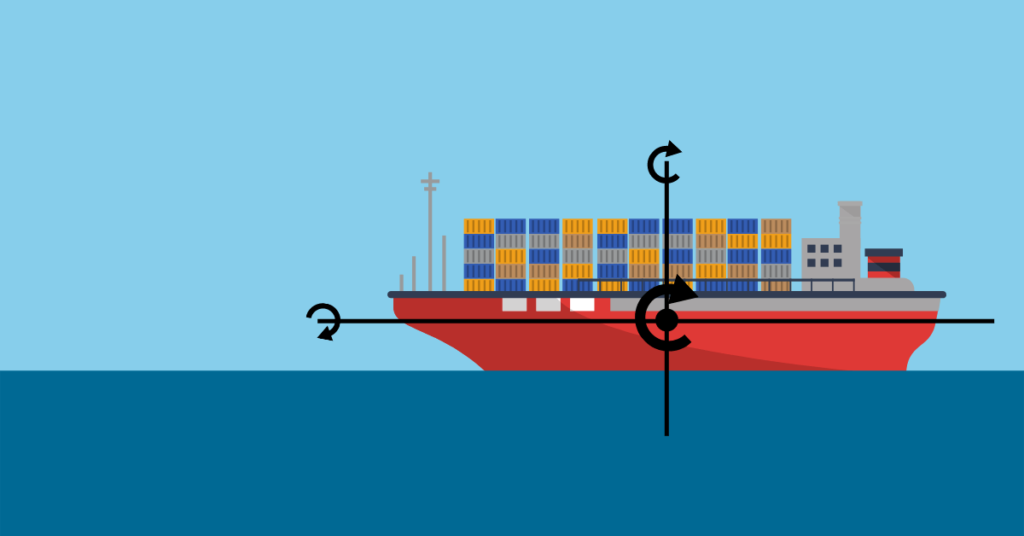

2. Directionality and seakeeping

This is also another very crucial aspect. Skegs can be best compared to the tailfins in planes in this respect, with the difference being that in the latter, they are mandatory. In contrast, in ships, they are not as ships speeds are relatively much lesser and have the stable buoyant support of the water, so losing directionality (if any) is not very sudden and drastic as well as risky.

In older vessels, especially smaller ones, skegs were common to maintain course and not veer away. However, in modern and bigger vessels, due to improved rudder and advanced navigational as well as stabilisation technologies like thrusters or DPS, skegs are not very important from a course-keeping point of view.

Nonetheless, skegs have been found to be useful in yaw control and reducing sway motions as well. Furthermore, skegs also play an important role in seakeeping by improvising stability and vertical balance characteristics like increasing roll damping. So, to date, skegs are incorporated in designs of many vessels, especially finer-form ones with low displacements.

3. Strength, protection, and support

Though it is not an intrinsic part of the structural members of a vessel, it definitely contributes to the longitudinal strength. It also provides a significant amount of support not only to the outer hull plating but also to the rudder and propeller as well during events of grounding but absorbing loads. During regular operations like drydock as well, it is also useful in supporting the hull when it rests on a solid surface.

Sometimes, skegs may be ballasted as well. They can also bear stern tubes for the aft propeller shafts in some designs.

Skegs are usually welded to the outer hull at the last stages of construction.

You might also like to read-

- What is a Skeg Guard?

- Understanding Vessel’s Hull Speed And Its Determination

- Advantages And Disadvantages Of Bigger Vessels For Port And Terminal Operators

- What Is Mooring Of Ships?

- Safety Features On LNG-Powered Ships

Disclaimer :

The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

About Author

Subhodeep is a Graduate of Naval Architecture and Ocean Engineering. He has deep interest in marine structures and goal-based design aspects, and is dedicated to sharing and propagating technical knowledge of the industry.

Disclaimer :

The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

Related Articles

⚓️ Enhance Your Knowledge. Prevent Accidents. Stay Safe at Sea.

1. eBooks for Engine Department

Master machinery operations, troubleshooting, and safety procedures with expertly written guides tailored for marine engineers. Prevent costly breakdowns and onboard accidents through practical knowledge.

👉 Explore Engine Department eBooks

2. eBooks for Deck Department

Sharpen your seamanship, navigation, and cargo-handling skills with real-world case studies and practical insights designed for deck officers and cadets.

👉Discover Deck Department eBooks

3. eBooks on Electrical Fundamentals & Issues

Understand marine electrical systems, identify potential faults, and prevent onboard electrical failures with step-by-step explanations from industry experts.

4. Pocket Guides for Quick Reference

Compact, handy, and loaded with essential checklists—perfect for on-the-go reference during operations and emergencies at sea.

5. Combo Packs to Save Big

Access multiple expert eBooks at discounted prices. Ideal for professionals seeking complete safety and operational knowledge across various ship departments.

6. Digital Maritime Courses – Learn at Your Own Pace

Upgrade your competence with Marine Insight Academy’s online courses. Learn from industry professionals anytime, anywhere, and become a safer, smarter seafarer.

Subscribe To Our Daily Newsletter

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT