Crane Barges Explained – Everything You Wanted To Know

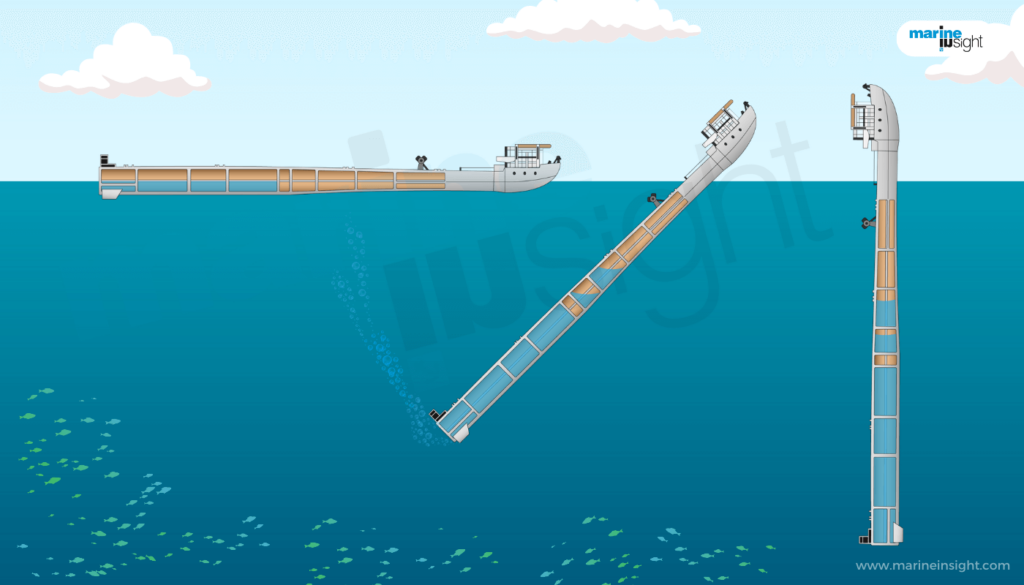

The term Crane Barge is constituted of two words: Crane and Barge. So, it can be well understood that crane barges are specialised vessels with a crane or a cranage system attached to their deck used for loading-unloading and lifting operations.

Now, while several cargo vessels have deck cranes, a crane barge is a vessel that is dedicated only to heavy-duty cranage operations and is not used for any other purpose. Mostly they are self-propelled and have the capability to venture into the high seas.

Thus, for all practical purposes, a crane barge can be considered as a floating lifting system for operations in the sea akin to the ones used for construction works on the ground. The concept of crane barge is not new and can be traced back to as early as the 14th century as lifting operations for construction in the sea have been there for over centuries.

Crane barges can be used for a wide range of activities like:

- All kinds of activities involved in offshore construction, installation, and repair work.

- Operations in rivers and canals. Piling is one of the common works that take place in river banks and canals. This involves driving filling materials known as piles for bank retention and reinforcement. Other operations involve installing bank protection materials like nicospan and also constructing embankments.

- Carrying out dredging operations in waterways.

- Installing pipework, cabling and other underground or underwater installations.

- Dismantling of civil structures in coasts, rivers, or in shallow water close to the shore.

- Salvaging operations of vessels grounded, damaged, or sunk.

Construction And Types Of Crane Barges

For all practical purposes, a crane barge has a simple hull form and has an open deck platform on which the crane or cranes are mounted.

From a design point of view, the crane barges are of the following types and configurations:

Simple cranes: They are flat hull-form barges with one or more simple lifting cranes installed. Larger configurations can lift loads in the order of 1000 to 2000 tonnes or sometimes more. These cranes can either be fixed or rotated.

Derrick Barges: They operate on a fully rotating crane system that is capable of lifting a very high modulus of loads. These are mainly used for offshore construction and repair work.

Smaller derrick barges have a lifting capacity of 50 to 500 tonnes whereas larger ones can have a capacity of over 1000 to 1500 tones.

Modern constructions of derrick barges have lifting capacities increased over time with sometimes the total capacity comprised of two or more cranes exceeding 10000 tones.

For all practical purposes, the derrick or derricks are located forward of the stern at a distance of about 20 to 25% of the length of the barge forward of the stern. The overall width of the barge should be such that the structural load distribution is uniform during the operation of the crane.

One of the problems often encountered by the derrick barge is the tendency of listing. So, often for the same reason, a counterweight is often placed to keep the barge in balance during no-load or partial load conditions.

During operations, the list can be further counteracted with the help of swing engines. Depending on the size and the lifting capacity of the derrick, there can be two to three swing engines installed.

The derrick barges, apart from their inherent capability to lift heavy loads, are also advantageous in terms of their flexibility and reach in any direction.

Sheerlegs: The sheerleg cranes consist of an A-Frame made up of tubular or truss-like structural members that are capable of lifting heavy loads. However, they are incapable of rotating. Sheer leg cranes come in a wide range of capabilities from 50 tones to as much as 10000 tones.

Amongst sheerleg crane barges, the larger ones are self-propelled while the smaller ones are often dumb and need to be towed from place to place. The propulsion system in sheerlegs is often on the deck or in outboard engine propellers.

During operation, the sheerleg barge positions itself in a favourable point of lifting lifts the load, and the sheerlegs adjust their positions to maintain equilibrium after the load is lifted. The deck engines of the sheerleg crane barges should be capable to counter various kinds of sea states that may bring about motions in all six degrees of freedom.

Heavy lift Crane Barges: These crane barges are used for lifting very high loads, primarily for offshore construction and installations. They are mainly of twin-hull configurations and the lifting device or crane rests on both the hulls with a symmetrical position. So, the load is lifted from in between.

The giant crane, which forms an interlocking arch-like structure between the two supporting hulls, is fixed and can extend up to a reasonable height to cater for lifting larger sized loads. These crane barges are often operated by heavy self-propulsion mechanisms or are towed by a number of tugs

Design Philosophy Of A Crane Barge

While we have so far discussed the utilities and the various types of crane barges, the design philosophy of all of them concerning an engineer or designer is centred on some common principles:

Strength and Integrity: One of the most important aspects of designing a crane barge is ensuring its structural strength and soundness. The sole purpose of a crane barge is to lift different kinds of loads based on requirements.

Henceforth, for a given barge of a given maximum crane lifting capacity, the entire structural engineering work needs to be carried out in such a way that when lifting within such load limits, the entire system remains unscathed. Now, speaking of the system, from a structural point of view, it can be further declassified into two heads:

1. The lifting system or cranage: This area is concerned with the capability or fitness of the lifting mechanism or cranage. The design of this is the same as any land-based crane whose main competence lies in safely lifting loads within the earmarked maximum limits, often in technical terms reckoned as Safe Working Limit or SWL.

We are all familiar with cranes, whether industrial or shipping or civil, being rated with a definite SWL capacity, operating beyond which can endanger the structural integrity of the system, leading to failure.

Similarly, cranes mounted on barges also have a similar rating which is the maximum permissible limit till which the loads can be lifted. Depending on the requirement, the crane is designed such that all its structural members like boom, leg or foundation can withstand the given load and operate seamlessly.

2. The Barge structure: Once the particulars of the cranage and the expected loads it is going to lift are decided, the hull structure of the barge is then designed accordingly. Like any other vessel, the hull is made up of suitable steel materials which are further reinforced by strengthening members. The most important part here is the deck plating.

The reason is obvious since all the loads coming from the crane and the weight lifted get absorbed primarily by the deck. So, not only is the thickness of the deck plating made adequate but also is stiffened for reinforcement.

The area of the plating which bears the cranage foundation is the most critical and is heavily reinforced and further fortified with added materials for transmissibility of the loads. From a structural point of view, twin-hull arrangements, like in heavy lift crane barges as mentioned above, are very much preferred for modern designs encompassing heavy loads because of very efficient load transmissibility and uniformity

Flotation and Stability: After loads, the next important point of concern is the aspect of flotation and stability. Lifting at sea is much more critical than lifting on the ground. And whenever there is any external load lifting involved, stability is a very big issue.

One very important point to be considered is that for a crane barge, the hull needs to be in a state of stable equilibrium during lifting operations both in the transverse and the longitudinal directions.

So, at this juncture, two important aspects need to be taken into account:

1. Placement of the Lifting System or equipment: The disposition of the cranage is a very important matter for stability as it cannot be installed at any random point.

The system needs to be placed at a carefully decided point such that during lifting operations for given maximum loads, the moment generated does not significantly alter the stability of the entire vessel. For a given area of the deck, no cranage should be placed at extreme ends or at the side shell but with a fairly marginal distance inward and towards the midships.

As the arm or the boom of the cranage is another important aspect for the moment consideration, its length is also carefully decided without compromising on its reach and lifting abilities. Twin-hull crane barges, where the cranage system is equally distributed and supported between two hulls, is the most stable arrangement for very heavy load lifting.

2. Stability of the Hull: Based on the cranage and the loads to be lifted, the hull is designed in such a way that both longitudinal and transverse stability is maintained.

Now, from a hull point of view, the design for stability is done in the same line as other vessels. The parameters or dimensions of the hull are decided in such as way that the entire arrangement remains in equilibrium in both full load and no-load conditions.

First and foremost, the barge should have dimensions such that the displacement in full load conditions is adequate for receiving the desired buoyancy without sinkage.

For transverse stability, the width and depth of the hull should be such that for the highest moment created due to the maximum possible load lifted coupled with the maximum outstretch of the arm, the vessel still remains intact.

Hence, most crane barges commonly have a high width to depth ratio. The increased deck area is also for stowage of the cargo lift. The depth along with the draft is also kept high such that in the even of maximum moments and even for some level of the list, the countering moment remains sufficient.

However, unnecessarily very high depths are avoided as they can increase the weight of the hull itself, something not very desirable for loading purposes.

The stability parameters are calculated in a way that for listing of the vessel during lifting operations, the restoring moment generated is enough to take the vessel back to its upright position.

As mentioned above, often special features like swing engines or anti-roll devices are incorporated into modern designs to upkeep stability in all conditions.

Powering and Propulsion: As expected, a crane barge is meant for not only lifting but also transporting heavy loads from one place to the other.

For barges towed by tugs, the number and bollard pulling capacity of the tugs are based on the load the barge is carrying.

For self-propelled heavy load barges, the propulsion system is of very high calibration as it involves carrying the weight of the load lifted as well as itself. However, the speed requirements for such barges are very low.

You might also like to read:

- What are Tanker Ships?

- What are Container Ships: History, Types And Design

- What are Ro-Ro Ships?

- What are Bulk Carrier Ships?

- Types of Lifeboats Used On Ship

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

Do you have info to share with us ? Suggest a correction

Latest Type Of Ships Articles You Would Like:

About Author

Subhodeep is a Naval Architecture and Ocean Engineering graduate. Interested in the intricacies of marine structures and goal-based design aspects, he is dedicated to sharing and propagation of common technical knowledge within this sector, which, at this very moment, requires a turnabout to flourish back to its old glory.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.