Different Types Of Sterns Used For Ships

When we look at the stern of a ship, we often wonder why ships have various types of aft end structures and what’s the purpose of each one of them.

While constructing and designing a ship, several factors such as hydrodynamic efficiency and construction simplicity, including types of hull, keel, bilge, flow patterns & aesthetics, are considered.

Each part of a ship has its unique function and utility. This article will look at the common types of ship sterns.

A ship’s stern is the back or aft-most part of the boat, meaning the very back of the vessel. It is the area constructed over the sternpost which extends upwards from counter rail to taffrail.

Stern is opposite the bow, the front of a boat or vessel. Also, most large ships like cruises have engine rooms at their sterns. A luxury cruise ship may also have a dining room at its stern as the rear part of the vessel offers the best ocean views.

Apart from the stern, which is the rear of a boat, while looking towards the bow, the left-hand side of the boat is called the port side, and the word for the right side of a boat is starboard side.

The following criteria govern the choice of the ship’s stern form:

- It should be designed to provide low resistance

- It should be able to provide high propulsion efficiency by ensuring a uniform inflow of water to the propeller

- The stern design must avoid vibrations.

Common Types of Ship’s Sterns

The sterns can be broadly classified into the following –

- Elliptical Stern

- Cruiser Stern

- Transom Stern

The topside and the underwater form the two major parts of the stern. The above three types represent the topside.

In addition to those mentioned above, there are numerous other special forms. Different types of stern include raked (or transom raked), transom flat, sugar scoop, lute stern & bustle stern etc., which are used on small vessels or yachts and are derivatives of the above three major types.

Also, these sterns can be used in combination of two, such as flat transom & sugar-scoop together, also known as constanzi stern, which was used in the case of Queen Mary 2 for better efficiency and flow around the stern.

Considerable attention is paid to the overall design of the stern to improve the flow into and away from the propeller. The cruiser stern was for many years the favoured stern type for ocean-going ships, but today most of these vessels have a transom stern.

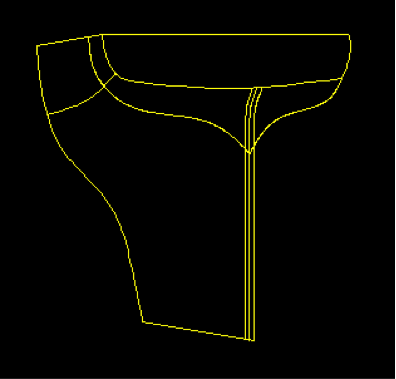

Elliptical Stern

Merchant stern or elliptical stern or counter stern was the conventional form for cargo ships during the early 20th century. If viewed from above, the deck line and the knuckle line are roughly elliptical. Counter stern or cutaway sterns are characterized by an upwardly curved profile, beginning fore of the aft perpendicular. They are similar to cruiser stern. However, on the counter, the cutaway for the rudder occurs above the waterline, and consequentially the counter stern has a pronounced aft overhang and exposed skeg. Benefits of having a counter stern include larger deck space in the aft, a measurable amount of reserve buoyancy provided, and an aesthetic choice for the owner.

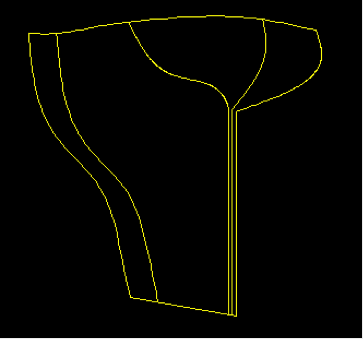

Cruiser Stern

The cruiser stern was initially designed only to lower the steering gear below the armour deck. A cruiser stern is characterized by an upward curved profile from the after perpendicular to the main deck or poop. Unlike the counter stern, a cruiser stern cutaway for the rudder occurs below the waterline (the rudder is fully submerged at the design waterline). The cruiser has better resistance characteristics than the merchant stern. The length of the waterplane with a cruiser stern is greater than Lpp. A cruiser stern presents a more pleasing profile and is hydrodynamically efficient.

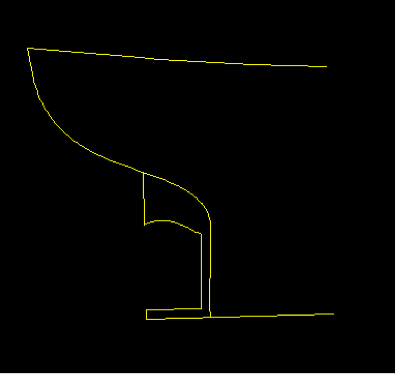

Transom Stern

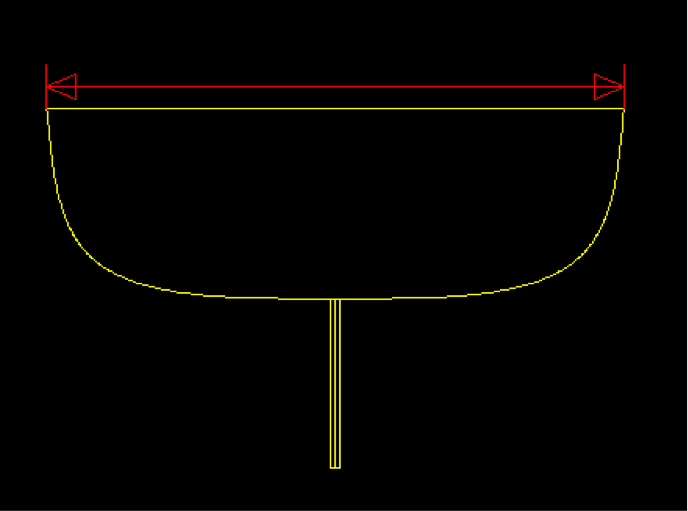

A transom stern is a stern shape characterized by a generally flat shape extending to the waterline. The transom stern offers a greater deck area aft, is a simpler construction, and can also provide improved flow around the stern. The flat surface of any transom stern may begin either at or above the vessel’s waterline. A transom stern can be viewed as a cruiser stern whose aft-most portion is cut off.

Design considerations on a deeply submerged square or transom stern:

- The edges of the square stern must be sharp so that the flow separates cleanly

- While optimising the design of the stern, stability of the ship is given more priority to the width of the stern

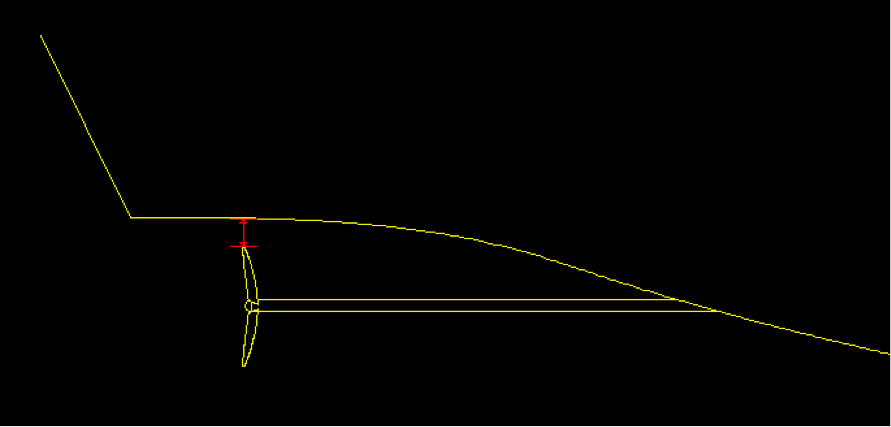

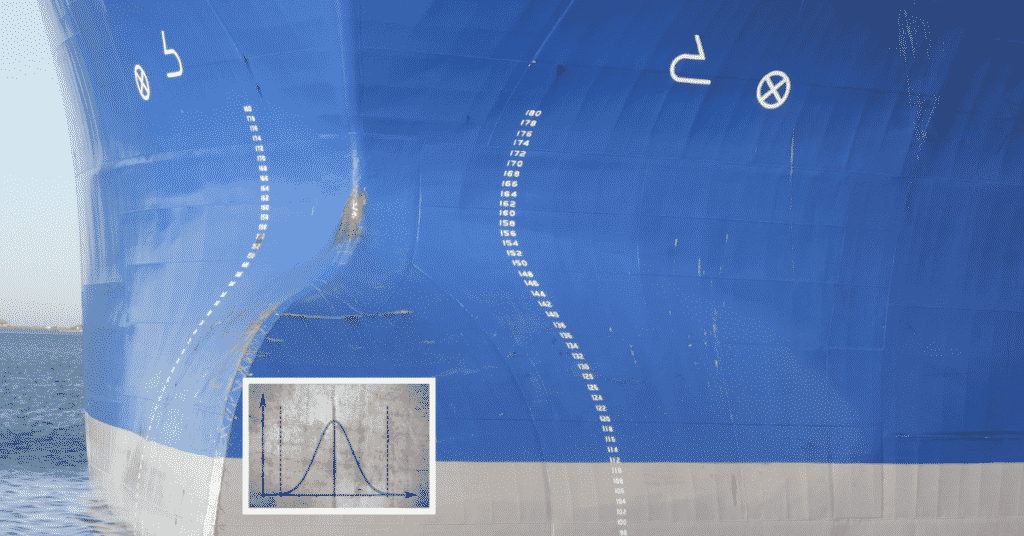

- The stern, and in particular its underside, influences the propulsion efficiency. The lesser the turbulence in the area between the propeller and the outer shell above the propeller more its efficiency will be. The space marked in red denotes the clearance area.

- The resistance in slow-speed operation is noticeably higher in a transom stern than in a ship with a cruiser stern due to the formation of vortices.

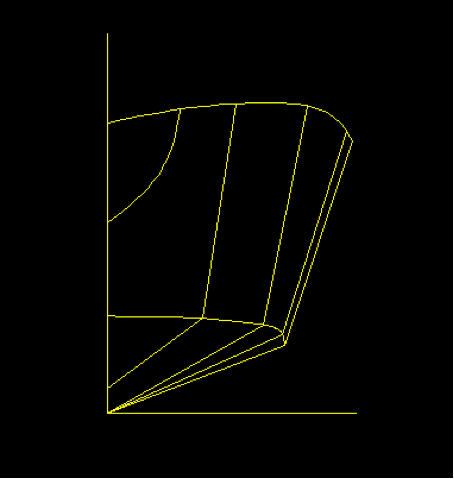

- The deck on transom stern ships can easily get wet during reversing operations and in a heavy sea. The water is damped up. Flare and knuckle deflect the water better during astern operations avoiding deck flooding. The AutoCAD model given below shows a knuckle or chine of the ship.

The reduction in power of a transom stern compared with the cruiser increases with Froude number, i.e., approx. 10% at Fn = 0.5. This reduction in power is less because the reduction in resistance is less at the cost of improving the propulsion efficiency.

The special case of Queen Mary 2

The Naval Architects of Queen Mary 2 designed a hybrid stern by welding a rounded into a square shape in response to the rough seas the ship would experience in a North Atlantic winter. This is known as a Constanzi Stern. A constanzi stern provides the transom required for azimuthal pod propulsions and provides better sea holding characteristics following a swell than a standard transom stern.

Stern Construction

The stern construction is one of the most challenging tasks during ship production. As the cruiser’s stern overhang may be subjected to large slamming forces, a substantial construction with adequate stiffening is required. Solid floors are fitted at every frame space, and a heavy centre girder is fitted right aft at the shell and decks.

Cant frames or webs stiffen the stern plating with short cant beams supporting the decks and leading to the adjacent heavy transverse deck beam. Further stiffening of the plating is provided by horizontal stringers extending to the first transverse frame.

Cant frames are not required where the transom stern is adopted, as the flat stern plating may be stiffened with vertical stiffeners. Deep floors and a centre girder are provided at the lower region of the transom stern construction.

White navigation lights indicate the stern end of ships at night. The hull section before the stern has a series of U-shape frames fixed in a sloping or cant arrangement. The last frame prior to the stern is known as fashion timber or fashion piece, as it is used for ‘fashioning’ the aft part of the vessel.

A lot of research is still carried out to find even better & effective aft-end structures to improve the hydrodynamic efficiency of the vessel. From a single stern design to a combination of two stern designs, tickle your grey cells a little harder, and maybe you can revolutionise the design of the aft–end structure.

Over to you.

Do you have more information on different factors for choosing a ship’s stern?

Let us know in the comments below.

Frequently Asked Questions

1. What is the purpose of a stern of a ship?

The purpose of a ship’s stern is to offer space for the tiller and steering device. In a few vessels, the outboard motor is also situated there. This motor moves the boat forward and is connected to a propellor.

2. What is the difference between aft and stern?

Aft is the vessel’s an inside or onboard rearmost part, while the stern is the outer or offboard rearmost part. The stern lies opposite the bow. The word derives from the Old English word ‘aeftan’ meaning behind.

3. What are the side walls of a ship called?

In shipbuilding, any vertical panel is called a head. Hence, the walls fitted side to side in the vessel’s hull are known as bulkheads. Bulkhead refers to every vertical panel aboard a ship, except for the hull.

4. What is the stern tube and its function?

It is a hollow tube with bearings, seal boxes and a propellor shaft. It is filled with oil, grease and water. It forms a barrier between the outside water and the ship’s engine room.

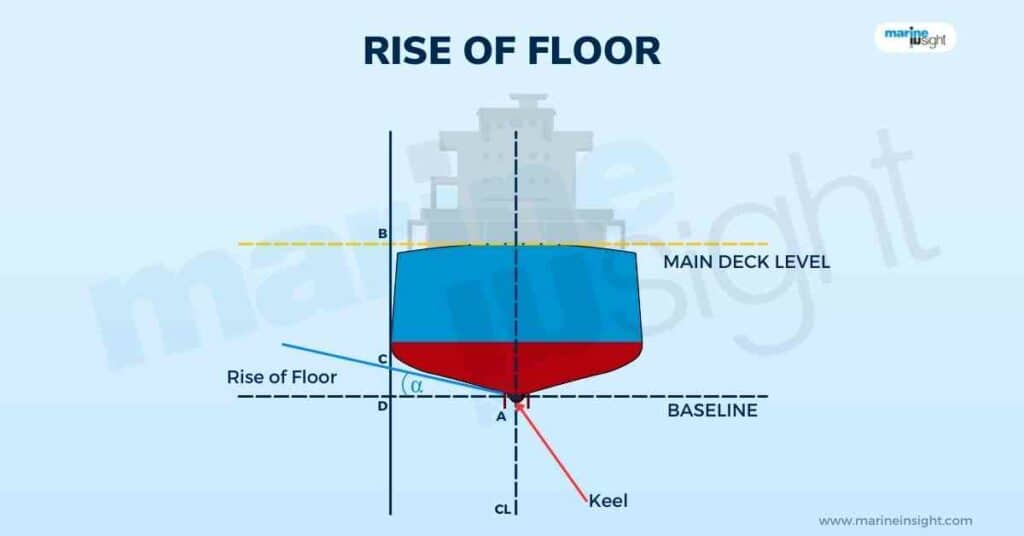

5. What is the bottom of a ship called?

A structural keel is a bottom-most member around which the hull of a vessel is constructed. The keel runs along the ship’s centreline from the bow to the stern.

You might also like to read

- How to Perform Ship’s Stern Tube Integrity Test in The Dry Dock?

- How Can COMPAC Stern Tube Bearing System Prevent Oil Pollution?

- Real Life Accident: Hull Damage After Contact With Bunker Vessel

- Understanding Stern Tube Arrangement on Ships

- How Sighting, Boring and Alignment of Ship’s Propeller Shaft Done?

- How Baltic Mooring of Ship Done?

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

can any one explain better and in simple language what is transom and cruiser stern and which one is effective

rajneesh kumar – ask yourself this question- name ANY warship that uses a cruiser stern??