Ballast Water Exchange and Management Plan – Everything You Wanted to Know

Ballast water has been an integral component of the ship’s stability since the steel-hulled vessels have been introduced.

Whether or not the ship is at sea, ballast water is carried on all seagoing vessels big or small to maintain acceptable stability conditions. A good ballast water management plan is imperative for all types of ships.

Ballast water reduces stresses on the vessel’s hull, balances off for the weight loss due to consumption of water and fuel, provides better manoeuvrability with sufficient vessel draft, including ship propeller immersion, and also helps in improving living conditions of the crew aboard by reducing vibrations and uncontrolled vessel’s movements.

Why is Ballast Water in Discussion?

While ballast water remains indispensable for safe, secure and effectual shipping operations, it has been scientifically researched and proven by expert authorities that ballast water is a significant path for the transfer of harmful and equally damaging aquatic organisms and other pathogens that pose serious ecological, economic and health problems and if introduced into the sea including estuaries, or into fresh water courses, may create hazards to the environment, human health, property or resources, impair biological diversity or interfere with other legitimate uses of such areas.

The introduction of these harmful marine organisms and other similar pathogens has caused major damage to many of the worlds’ coastal regions and bio-diversities over the years.

Examples of such organisms are Golden Mussels, Zebra Mussels, North American Comb Jellyfish, the Cladoceran Water Flea, and the North Pacific Seastar.

Steps To Reduce Hazards Associated with Ballast Water

The global community, under the administration of IMO has adopted the “International Convention for the Control and Management of Ship’s Ballast Water and Sediments, 2004”.

This Convention is intended at stopping the introduction of superfluous aquatic organisms and pathogens through the discharge of ballast water and sediments.

The Ballast Water Management (BWM) Convention is applicable to new and existing ships that are designed to carry ballast water and are of 400 gross tonnages and above.

The BWM Convention entered into force on 8th September 2017. In order to show compliance with the requirements of the Convention, each ship shall have on board a valid Certificate, a Ballast Water Management Plan and a Ballast Water Record Book.

The Convention includes two regulations that define ballast water management standards;

– Regulation D-1 addresses the Ballast Water Exchange standard and

– Regulation D-2 details the Ballast Water Performance standard towards the treatment of ballast water using Type Approved Ballast Water Management System.

The accountable authorities, which includes scientists, ship owners and operators as well as flag States, have determined that the method of ballast water exchange provides an effective means, to prevent the unintended transfer of these harmful marine organisms.

This, of course, is on a temporary basis until the authorities come up with a permanent solution related to ballast water treatment systems.

Where Ballast Water exchange is to be conducted?

Ballast water exchange cannot be carried out anywhere at sea. There are certain requirements that must be complied with to perform a ballast water exchange at sea.

1. Conduct ballast water exchange at least 200 nautical miles from the nearest land and in the water of at least 200 meters in depth.

2. When a ship cannot meet the above criteria due to reasons such as short voyage duration or enclosed waters, the exchange is to be conducted as far from the nearest land as possible, but at least 50 nautical miles from the nearest land and in a water depth of at least 200 meters.

A Port State, in consultation with adjacent or other States, may designate areas where ballast water exchange may be conducted if there are locations of operation where the distance from nearest land and water depth do not meet the above requirements.

National ballast water management regulations must be consulted in advance for proper planning. It is often mandatory to submit a ballast water management report in many ports prior to arrival.

Any ballast exchange must take into account any Particularly Sensitive Sea Areas or Marine Protected Areas.

What is Ballast water exchange and who’s responsible for its management?

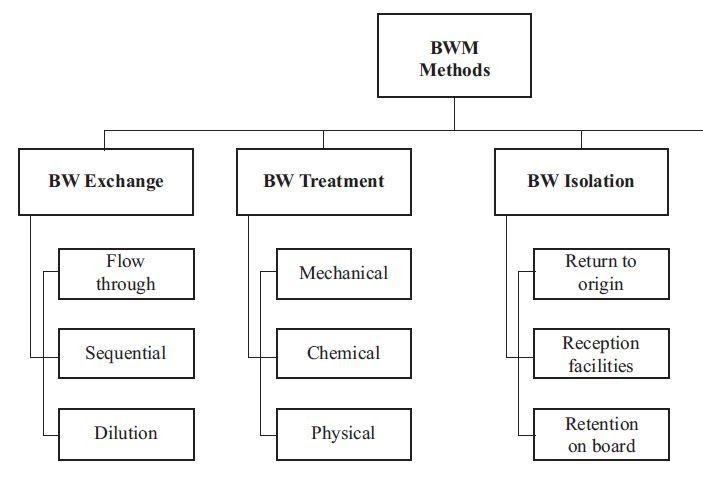

Ballast water exchange is a process which involves the substitution of water in ship’s ballast tanks using either a sequential, flow-through, dilution or other exchange methods which are recommended or made obligatory by the IMO, in order to preserve ecology in biologically rich coastal waters and similar to those in deep oceanic waters.

Since it has been scientifically established that those marine organisms and/or pathogens are taken on in coastal waters are less likely to survive when discharged into the open ocean due to changes in the water’s chemistry, temperature and salinity, and similarly, those organisms taken onboard in oceanic waters are less likely to survive in coastal waters, Ballast Water Exchange or BWE is required to be carried out during the vessel’s voyage through various zones of the seabed.

The quantity, distribution and circulation of ballast water are determined by the Master of the vessel and are based out of explicit operational and environmental conditions. The vessel’s Master and the designated “Ballast Water Management Officer” are the responsible authorities for the implementation of the Ballast Water Management Plan.

The Ballast Water Exchange Methods:

D1 – Exchange: Ballast water exchange is based on the principle that organisms and pathogens contained in ballast water taken on board from coastal waters will not survive when discharged into deep oceans or open seas, as these waters have different temperatures, salinity and chemical composition.

1. Sequential method: In this process, the ballast water tank is first emptied and then refilled with replacement ballast water to achieve at least a 95 per cent volumetric exchange. All of the ballast water in each tank should be discharged until suction of the pumps is lost and stripping pumps or eductors should be used if possible, to avoid a situation where organisms are left in the bottom of the tank, the tank is then refilled with new water. Emptying of tanks can be done individually or in pairs.

2. Flow-through method: The flow-through method is a process by which replacement ballast water is pumped into a ballast tank intended for the carriage of ballast water, allowing water to flow through overflow or other arrangements in order to achieve at least 95 per cent volumetric exchange of ballast water. Pumping through three times the volume of each ballast water tank shall be considered to meet the standard D-1.

3. Dilution method: The dilution method is a process by which replacement ballast water is filled through the top of the ballast tank intended for the carriage of ballast water with simultaneous discharge from the bottom at the same flow rate and maintaining a constant level in the tank throughout the ballast exchange operation.

At least three times the tank volume is to be pumped through the tank. Commonly two ballast pumps are used simultaneously, whereby one is acting as filling pump and the other as a suction pump. As it is essential to keep the filling level in the tanks constant, exact control of the pumped volume of both pumps is to be ensured.

D-2- Performance standard defines the performance standard for the ballast water treatment system. The D-2 standard specifies the maximum amount of viable organisms allowed to be discharged, including specified indicator microbes harmful to human health:

Ships conducting ballast water management in accordance with this regulation shall discharge:

• Less than 10 viable organisms per m3 > 50μ in minimum dimension, and

• Less than 10 viable organisms per ml < 50μ and>10μ in minimum dimension, and

• Less than the following concentrations of indicator microbes:

– Toxicogenic Vibrio cholera less than 1 colony-forming unit (cfu) per 100 ml, or less than 1 cfu per 1 gram zooplankton samples

– Escherichia coli less than 250 cfu per 100 ml

– Intestinal Enterococci less than 100 cfu per 100 ml.

Compliance with the Performance Standard (D-2) seems to be achievable only by use of a BW treatment system. In general treatment systems that comply with the standard D-2 shall be approved by the Administration.

The Ballast Water Management Plan

This Ballast Water Management Plan has been developed to provide guidance and assistance to the vessel’s crew and operators in the effectual operation of the ballast water exchange system.

The accomplishment of this plan enables the vessel to prepare for the steps and proceedings required when conducting ballast water exchange.

Since Ballast water exchange operations are more hazardous than normal port operations, vigilant and calculated planning has to be carried out beforehand.

It is the duty of the vessel’s Master and the “Ballast Water Management Officer”, usually the Chief Officer to develop detailed measures and processes related to the ballast water exchange.

All concerned are to be familiar with the safety aspects of ballast water exchange and ballast water management plan, in particular with the method/s of exchange to be used onboard their vessel.

The Master and crew engaged in ballast water exchange at sea should be educated in and familiar with the following, as appropriate:

i) The approved vessels loading conditions to be used during ballast water exchange

ii) The vessel’s ballast pumping and piping arrangements, positions of associated air and sounding pipes, positions of all compartment and tank suction and pipelines connecting them to the vessel’s ballast pumps and, in the case of use of the flow-through method of ballast water exchange, the openings used for the release of water from the top of the tank together with overboard discharge arrangements

iii) The means of confirming that the sounding pipes are clear and that air pipes and non-return devices are in good order

iv) The distances off the coast required to undertake the various ballast water exchange operations. This will also include the time required to complete individual tanks

v) The method/s to be used for ballast water exchange at sea, e.g. Flow-through, dilution, etc.

vi) The need to incessantly monitor ballast water exchange operations

The contents of a BWMP can be summarised as below:

1. Ship specific particulars – which includes class, IMO number, flag state, GRT, Main dimensions, total ballast water capacity, No. and capacity of ballast pumps, Total number of segregated ballast tanks on board, capacities, centres of gravity, max. free surface, Units used for ballast measurement, Appointed BWM officer.

2. Plans and diagrams which include Tank arrangement and capacities, A piping diagram of the ballast system and a layout diagram of the ballast control system, A list or set of diagrams showing sampling and access points in pipelines and tanks. These sampling points are to be provided so as to enable the port State officers or other interested parties to confirm that a ballast water exchange has been conducted prior to the discharge of ballast water.

3. Safety considerations – various circumstances that may affect the ship safety during the ballast water exchange process but not limited to stability considerations such as minimum required GM, strength considerations such as avoiding over pressurisation of tanks, limits of longitudinal and torsional strength, training of officers and crew

4. The preferred method or methods of ballast water handling.

5. Duties of appointed ballast water management officer

6. Sediment management– Residuals of sediment taken in the ballast water tanks can contain an assortment of microorganisms, including resting stages. When tanks are later filled with ballast water the accumulated sediment and associated biota may be re-suspended and discharged at subsequent ports of call.

Ballast water tanks and their internal structure should be designed to minimize accumulation of sediments and allow for easy cleaning and maintenance, as required by BWM Convention.

The volume of the settled down sediments should be regularly monitored and regularly removed in accordance with the Ballast Water Management Plan. Release of sediments during the cleaning of ballast tanks should be avoided as much as possible.

The pre-planning of ballast water exchange should include the following:

- establishing which tanks are subject to Ballast Water Management

- establishing which exchange method is to be taken

- calculation of each intermediate stage with the loading instrument on board (e.g. for sequential method)

- calculation of the estimated time span

- establishing in which areas ballast water exchange is possible

- because of the possibility that partial exchange may encourage re-growth of organisms, ballast water exchange should only

- be commenced in any tank if there is sufficient time to complete the exchange for that tank

- consideration of limitations contained in this Ballast Water Management Plan

- If a tank couple will be operated simultaneously with both BW pumps running, the tank levels have to be controlled continuously and if necessary one line has to be reduced. In any case, it has to be ensured that a single tank is filled or discharged by only one pump to avoid unacceptable high pressure.

Environmental Conditions

Throughout the ballast water exchange process, the Master has to take into consideration the following:

1. The vessel’s position including traffic density.

2. Weather forecasts and sea condition.

3. Vessel’s stability and loading conditions.

4. Condition and performance of the vessel’s machinery and manoeuvrability.

When it is imperative to load ballast water on board, few of the following key points must be kept in mind to minimise the uptake of potentially harmful aquatic organisms and pathogens or sediments containing such pathogens.

- areas identified by the port state in connection with warnings provided by ports concerning ballast uptake and any other port contingency arrangements in the event of emergency situations

- in darkness when organisms may rise up in the water column

- in very shallow water

- where propellers may stir up sediment

- areas with current large phytoplankton blooms (algal blooms such as red tides)

- nearby sewage outfalls

- where a tidal stream is known to be more turbid

- where tidal flushing is known to be poor

- in areas close to aquaculture

- where dredging is or recently has been carried out.

- In areas with naturally high levels of suspended sediments, e.g. river mouths, and delta areas, or in locations that have been affected significantly by soil erosion from inland drainage.

Duties of the ballast water management officer:

- ensure the safety of the vessel and crew

- ensure that ballast water management procedures are followed and recorded

- be familiar with the requirements of the Port Authorities with respect to ballast water and sediment management

- where ballast exchange is required, ensure that the steps of the ballast exchange sequence are followed in the prepared order.

- ensure adequate personnel and equipment are available for the execution of the planned ballast water management operations

- ensure all required ballast water management records are maintained and up to date, including the ballast water record book

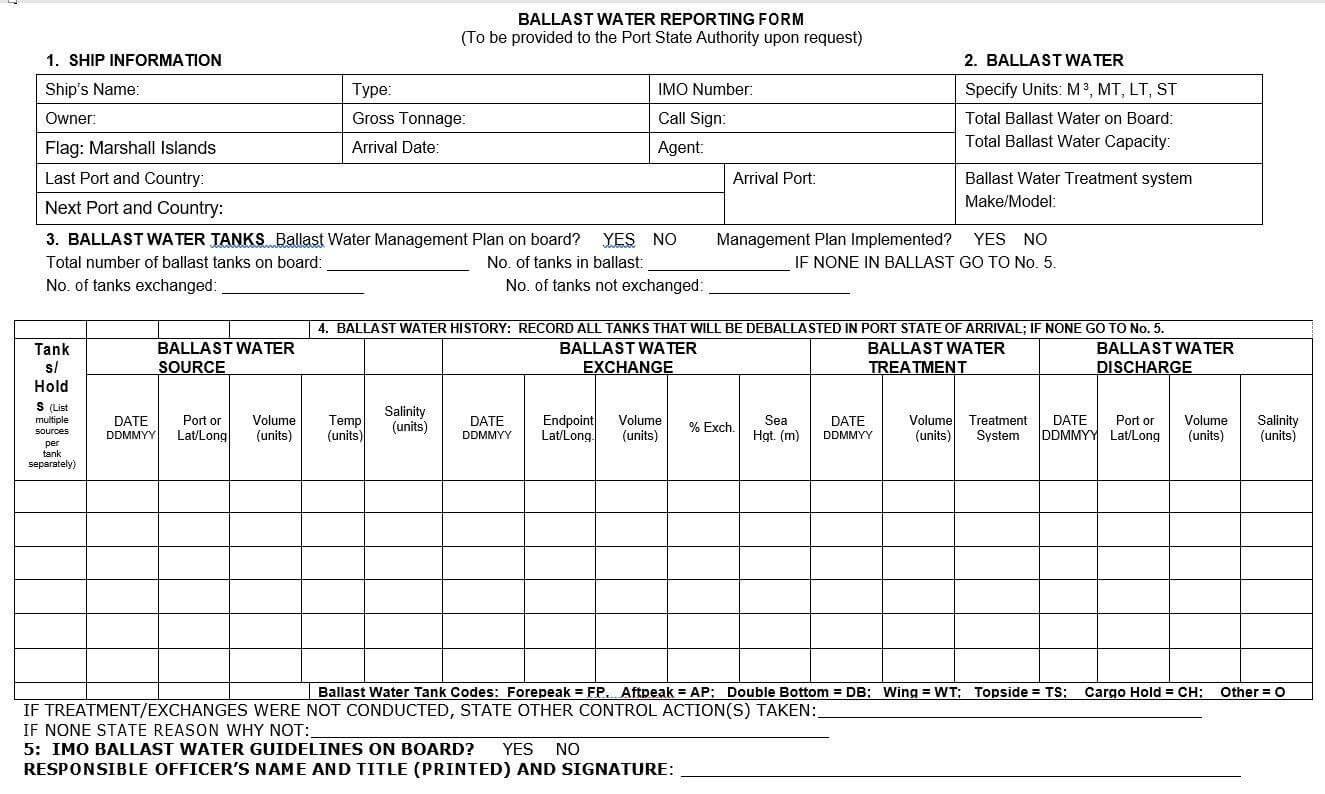

- where required, prepare the appropriate national or port ballast water declaration forms prior to arrival

assist the port state control or quarantine officers for any sampling that may need to be taken - undertake familiarisation and training of crew in ballast water management requirements and applicable shipboard systems and procedures

- other duties, as specified by the company.

- ensure that the manholes of the specific tanks are opened prior to commencement of the flow-through method or instead, for tanks with no direct access to open deck the vent heads are removed. It is also the responsibility of the officer to ensure that these are re-secured after completion of the operation.

It is necessary that the ballast water management officer keeps the Master advised on the progress of the ballast water management operations and any envisaged deviations from the agreed plan.

Record keeping

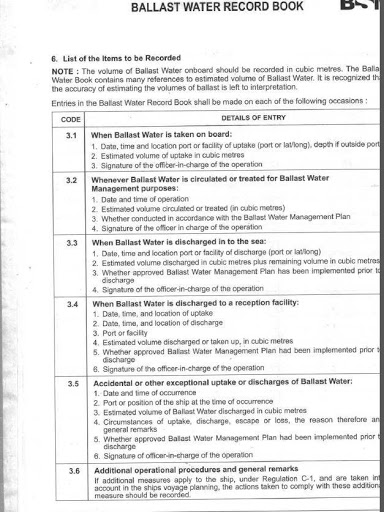

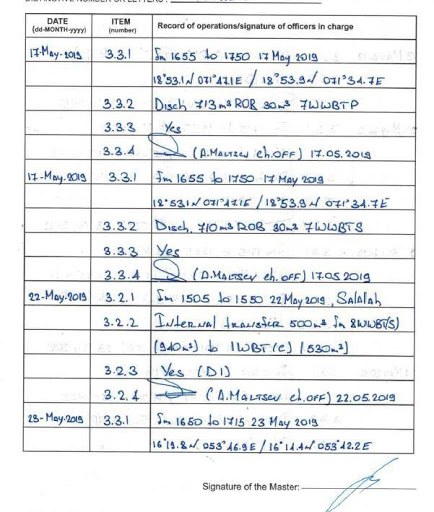

Each procedure concerning ballast water exchange is to be fully recorded without delay in the ballast water record book (An integral part of the ballast water management plan).

These records are considered to be critical to the success of the ballast water management plan and dole out to provide documentation that the ballast water exchange has been properly conducted and the exchange has been completed.

Also included should be a list that identifies a representative listing of those items that may be considered for inclusion as a section of the Ballast Water Management Plan, as follows:

i) The location (Lat/Long) where ballast water exchange is to occur is to be identified.

ii) A detailed position and description of the watertight and weathertight closures (e.g., manholes, the opening of vents and air pipes) which may have been opened during ballast exchange that must be re-secured.

iii) Descriptions of the procedures required to conduct ballast water exchange and the estimated volume of ballast water which includes the following:

1. When ballast water is taken onboard

2. Whenever ballast water is circulated or treated for ballast water management purposes

3. When ballast water is discharged into the sea

4. When ballast water is discharged to a reception facility

5. Accidental or other exceptional uptake or discharge of ballast water

6. Additional operational procedures and general remarks.

There are codes provided at the beginning of a ballast record book. All entries are to be made in reference to these codes. Below attached is an example of record-keeping for clear understanding.

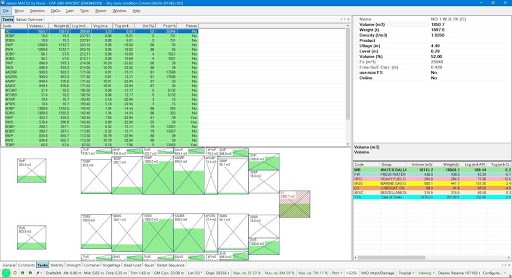

The picture above shows the ballast sequence planned for a vessel. Note the tanks containing ballast water, some partially and some fully. Factors such as trim, stability and visibility are all taken into account prior planning a ballast sequence.

Authorized Port State Officers may inspect the ballast water record book on board the vessel as a means to determine the status of exchange completed.

These officials may choose to make a copy of the entries in the record book and require the vessel’s Master to certify that the copy as a true copy.

Any copy so certified may be permissible in any legal proceedings as evidence of the facts stated in the entry of ballast water management plan.

It is quite clear from the above explanation that our ultimate aim is to prevent pollution caused by ballast water from one location discharged to another location.

It is to be noted that the ballast water exchange standards that are D1 is temporary and sooner or later all ships have to comply with the performance standards D2, which implies that all vessels must have a ballast treatment plant.

Thus it is clearly understood that vessel must comply with either D1 or D2. The scheduling deadline for compliance with D2 can be simplified as below:

- All-new ships (ships built on or after 8th September 2017) must comply with D2 performance standards.

- All existing ships (ships built before 8th September 2017) are required to meet the D2 standards at the first IOPP renewal survey after 8th September 2019 and

- All vessels must comply with D2 standards before 8th September 2024.

Since the International Convention for the Control and Management of Ships’ Ballast Water and Sediments, 2004, entered into force globally on 8 September 2017, ships in international traffic are required to manage their ballast water and sediments to a certain standard and have to carry a ballast water management plan, a ballast water record book and an International Ballast Water Management Certificate.

Ballast water management systems must be approved by the Administration taking into account IMO Guidelines. Carriage of ballast water is indispensable to maintain acceptable load and trim conditions during a specific voyage or a segment of a voyage.

All guidelines and BWMP should be followed during any ballast exchange to avoid significant adverse impact to many of the world’s coastal regions.

Proper training and familiarization of the vessel’s crew are essential in the management of ballast water.

When conducting ballast water exchange, the vessel’s Master, Ballast Water Management Officer and crew are to maintain a diligent watch in order to respond to power failures, ballast pump or pipe failures, or structural failures without much delay.

You might also like to read:

- 10 Important Points to Comply With Ballast Water Convention

- How Ballast Water Treatment System Works?

- Different Technologies For Ballast Water Treatment

- What is Ballast Water Management Plan?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

Bikram Pal Singh is a professional mariner and blogger. He has sailed extensively, serving on various Oil tankers and Offshore Vessels. He enjoys reading and compiling notes about critical shipboard operations and crew psychology.

Latest Maritime law Articles You Would Like:

Latest News

- What is the Purpose of DG Shipping?

- What are Logistics Risks?

- How Port and Terminal Operators Can Control Emissions?

- Minimum Quantity Commitment (MQC) and Liquidated Damages in Container Shipping: Concept and Relevance

- MARPOL (The International Convention for Prevention of Marine Pollution For Ships): The Ultimate Guide

- The Ultimate Shipping Container Dimensions Guide

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

THANKS

How can I find the list of countries that require ballast exchange and the ones which do not.

You state

“When it is imperative to load ballast water on board, few of the following key points must be kept in mind to minimise the uptake of potentially harmful aquatic organisms and pathogens or sediments containing such pathogens.

areas identified by the port state in connection with warnings provided by ports concerning ballast uptake and any other port contingency arrangements in the event of emergency situations

in darkness when organisms may rise up in the water column

in very shallow water

where propellers may stir up sediment

areas with current large phytoplankton blooms (algal blooms such as red tides)

nearby sewage outfalls

where a tidal stream is known to be more turbid

where tidal flushing is known to be poor

in areas close to aquaculture

where dredging is or recently has been carried out.

In areas with naturally high levels of suspended sediments, e.g. river mouths, and delta areas, or in locations that have been affected significantly by soil erosion from inland drainage.”

Did you forget to put an A in front of the word few? If you purposely did not include the word A, you might want to consider what others who have studied this say.

As far back as 1996 the National Academy of Sciences has recommended best practices for Ballast Water Management are beneficial. According to National Academy Press (National Academy Press et al., 1996, pp. 1–3) “vessels could avoid taking on ballast in ports with high sediment loads, in areas of sewage discharge, or in “hot spots” where certain unwanted organisms were known to be present. A plan for managing ballast water, developed in conjunction with the ship cargo plan, would assist the ship’s master in adjusting ballast loading and discharging needs to meet constraints on ballasting in these locations. In addition, a requirement for official logs indicating when and where ballast was taken on or discharged would be helpful for implementing existing (and future) strategies for managing ballast water”

Additionally, WHO (World Health Organization) is in agreement with the BPMs as outlined in their 2011 ‘Guide to Ship Sanitation’ edition. “In some cases, ballast water treatment systems have failed to perform as required, resulting in unsafe situations. Therefore, reliance should not be placed on treatment and management systems alone. Multiple ballast management barriers should be actively maintained, including:

• filling with ballast water from safe environments wherever practicable;

• matching ballast treatment facilities to their required capacities;

• maintaining sound practices in discharging ballast water.

Staff at ports and ship crews need to be adequately trained in the protection of the environment, safe operation (including collection, handling and disposal of wastes) and relevant legislation.” (Ballast Water – Guide to Ship Sanitation – NCBI Bookshelf, 2011)

Obviously uptakes with lower concentration will be cleaned more effectively. Waters with lower concentrations will help to eliminate sludge build up, which will facilitate easier tank cleaning.

What action to be taken is BWTS fails while De Ballasting and Ballasting