What is OOG or Out of Gauge Cargo?

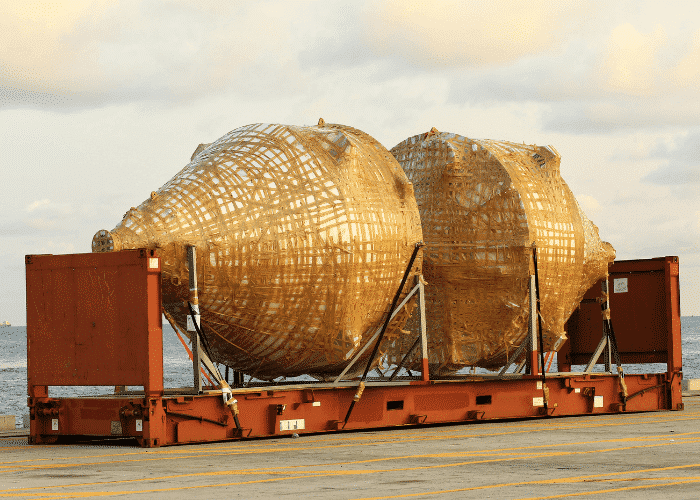

If your cargo is extremely large or has unwieldy booms and protrusions that do not fit into standard shipping containers then you have an out of gauge cargo on hand, shortened to OOG cargo.

The list of OOG cargo is long. Some examples are very large automobiles such as luxury coaches, automobile trailers, aircraft parts, parts of wind turbines, construction machinery, abnormally large parts of machinery used in electricity generation, etc.

Also referred to as AILs (Abnormally shaped Indivisible Loads), such out of gauge cargo exceed standard container dimensions and maybe extraordinarily heavy to be accommodated in rectangular shipping containers such as a twenty feet container (TEU) or a forty feet container (FEU).

The sheer dimensions and weight of such odd-shaped and odd-sized cargo require specialized heavy-duty equipment to handle them for transport by sea.

Unless they are handled with care and precision, such cargo can easily get damaged during transport.

Cost of Transporting Out of Gauge Cargo

Transporting out of gauge cargo can be a costly affair as it involves additional costs. The out of shape cargo eats into space that could have been used for other cargo.

When an OOG cargo is loaded on the deck or below-deck of a cargo carrier, neither can another container be placed and secured to the twist-locks on the adjacent sides of it nor can containers be placed on top of the OOG cargo, as in flat racks and platform containers.

Hence, the shipping and transport companies charge extra to make up for this wasted space. Space thus wasted is also referred to as ‘lost slots’.

Planning and Execution

An out of gauge cargo, if not secured or lashed properly to their containers can damage other cargo that is kept near it. Besides, when out of gauge cargo is placed onboard a vessel, its location has to be planned carefully as there will be other cargo that will have to be unloaded before the OOG cargo.

It is not only the sea voyage of the OOG cargo that has to be planned and executed correctly but also the overland transport from the manufacturing plant or its storage location to the port of loading.

Since some out of gauge cargo may have abnormal protrusions or could be extremely heavy, the type of trailer truck to be used for moving it and the appropriate gantry crane have to be chosen carefully and arranged. Next, the road route to be taken from the OOG cargo storage location to the port, up to the loading point, has to be planned.

The route to the seaport should be planned in such a way that busy roads and peak hours are avoided. There should be enough clearance on either side of the road and on top (over bridges, arches, etc.) for the OOG cargo to pass safely and also not to damage property.

Equipment

The most common options available for the transport of out of gauge cargo is flat racks or open-top containers.

A flat rack container usually has collapsible walls at either end of the container. The sides of the container are open and do not have walls.

Out of gauge cargo can be loaded in such containers from the sides or the top. When loading is from the side, it is normally done using heavy-duty forklifts.

If the cargo is loaded from the top, it is done using cranes. The cargo is usually placed in the centre of the container for optimal weight distribution.

Unlike a flat rack, the open-top container has rigid walls along its length and doors on one of its ends, like the conventional containers. However, the top is open or it may have a removable hard roof. The hard roof can be removed using a crane. Sideloading is not possible in open-top containers as they have rigid walls along the sides. Hence it is done through the door using a heavy-duty forklift or from the top using a crane.

In some type of open-top containers, the beam atop the door can be dismantled to facilitate the loading of gauge cargo through the door.

To help the movement of heavy-duty forklifts into the container some of the doors can be swivelled outward.

Once the out of gauge cargo is loaded, the cargo may be lashed to the floor of the container securely using straps. The open-top is then covered with a sturdy sheet such as tarpaulin or with the container roof.

Tarpaulin is a heavy-duty, flexible material that is commonly used to cover such containers or the out of gauge cargo. It is usually made of canvas coated with polyurethane or polyethene or other such water-proof plastics. It is quite versatile and will also conform to the shape of the out of gauge cargo. Plastic or canvas sheets can also be used to cover the container or cargo.

Most flat racks have pad-eyes or lashing-rings on their floor for lashing the out of gauge cargo or for tying the tarpaulin cover.

Flat racks and open top containers used in the transport of out of gauge cargo are mostly of the standard sizes of 20 feet and 40 feet. This is so that they fit on standard trailers and can be handled by the standard loading/unloading equipment at ports and warehouses easily.

Most of these containers have floors made of hardwood.

Flat Rack Containers

Flat racks are normally found in lengths of 40 feet and 20 feet. Out of gauge cargo can be loaded on to them from the sides using heavy-duty forklifts or placed on the floor from the top using a crane. They are therefore suitable for cargo such as abnormally-shaped machinery, boats, long tubular structures, etc.

A typical 40 feet flat rack container has dimensions of 40’ x 8’ x 8’ 6” (height of the end walls) and they carry a payload of approximately 25 tons. When the cargo is very long or too broad and does not fit on a single flat rack, two or more than two flat racks are connected to hold the cargo.

A 20 feet flat rack container has dimensions of 20’ x 8’ x 8’ 6” (height of the end walls) and they carry a payload of approximately 22 tons.

One advantage of flat rack containers is that empty flat racks can be stacked one on top of the other during storage to save space.

Open Top Containers

Open top containers also come in sizes of 40 feet and 20 feet, though custom-made containers are also available for special cargo. In such containers, cargo is usually loaded from the top using a crane or through the door using a heavy-duty forklift.

A 40 feet open top container has dimensions of 40’ x 8’ x 8’ 6”. These containers can carry a weight of up to 26 tons.

A 20 feet open top has dimensions of 20’ x 8’ x 8’ 6” (height of the end walls) and they carry a payload of approximately 28 tons.

The dimensions and payload capacity change between different makes of containers and container series.

Flatbeds or Platform Containers

Flatbeds or platform containers are also used to transport out of gauge cargo. As the name implies, they do not have any walls or a roof and hence the only restriction to follow is the weight of the OOG cargo.

A 20 feet flatbed with a floor-length of 19.88 feet has a payload of 31 tons. 40 feet flatbeds come in lengths of 39.99 feet each, with a payload capacity of 39 tons.

Like flat rack containers, flatbed containers can also be stacked one on top of the other during storage or transport of empties.

Payload

Why is the payload capacity between 20 feet and 40 feet containers disproportionate? If a 20 feet open top container can hold 28 tons, shouldn’t the 40 feet hold 56 tons?

This anomaly in payload between the two sizes of containers is because of the container design and weight restrictions of these designs. Carrying excess weight than what is prescribed by the container manufacturer can result in “container sagging’.

The container can crack under the excess weight causing damage to the cargo and other accidents.

Different countries may have different limits on container payloads. Since some out of gauge cargo weigh more than the prescribed limit, it is often disassembled and transported as parts and then later reassembled after reaching its destination.

Most of the containers that are used for carrying cargo have Safety Approval Plates in accordance with the CSC 1972 (Convention for Safe Containers 1972). This plate that is fixed on the container shows all the details of the container design and most importantly its gross weight. The gross weight is shown in both kilograms as well as pounds.

Gross weight is the total weight of the container and the payload it can carry. According to the CSC 1972, containers should undergo inspection at the container depot by certified inspectors within 5 years of the date of its manufacture and after that, once every 30 months to ascertain and certify their sea and road-worthiness.

Convention for Safe Containers 1972 (CSC 1972)

The International Maritime Organization (IMO) and the United Nations (UN) jointly promulgated a set of procedures for the handling of containers to ensure human safety during the transport of such containers. It set uniform international safety regulations to avoid confusion caused by the various regulations of different countries.

While the CSC 1972 applies to most transport containers, it, however, covers only containers of a prescribed minimum size. Containers that are covered under the CSC 1972 should be fitted with the Safety Approval Plate showing all the technical data pertaining to the container and its gross weight.

Over the last few decades, various amendments have been introduced to the original set of rules of CSC 1972 to incorporate additional safety and security measures.

Types of Cargo

Carriers transport cargo packed in containers, as dry bulk (mineral ores, grains, etc.), break-bulk (out of gauge cargo, oil drums, etc.), liquid bulk (crude oil, edible oil, etc.), and RO-RO or ROLL-ON/ROLL-OFF (normally automobiles that are driven into the carrier’s hold for transport and driven out of it upon reaching the destination).

The dimensions or weight of some out of gauge cargo may exceed the limits that normal equipment such as flat racks, open tops, or platform containers can handle.

In such cases, it is sometimes secured to the vessel directly, after taking into consideration the safety of the cargo, the vessel, and other cargo that are kept near the OOG cargo.

Monitoring Out of Gauge Cargo Onboard Ships

The deck officers of a cargo vessel are normally in charge of overseeing the loading and unloading of cargo. They work according to a loading/unloading plan which is prepared carefully. Slots to be left vacant adjacent to the out of gauge cargo must be planned.

For below-deck storage, the hatch cover clearance must be considered to avoid any damage to the cargo or the vessel. An even load onboard the vessel and an even discharge plan prevent the listing of the vessel especially when very heavy out of gauge cargo is present onboard the ship.

Good knowledge of the ballast operations and associated instruments help deck officers in their job. They have to ensure that OOG cargo is fixed to the twist-locks and lashed properly to the deck.

Rough seas can often cause these to come loose and therefore the deck officers must conduct periodic supervision during the sailing.

Out of Gauge Rate

Shipping companies usually require the following information from the shipper to provide them with a rate for transport of the out of gauge cargo.

- Description of the out of gauge cargo.

- Dimensions (longest length x broadest width x tallest height).

- Weight of the OOG cargo in kilograms.

- Point of loading.

- Point of discharge.

- Photos or drawings (front, side, and top views) showing the centre of gravity.

- Lifting points of the OOG cargo.

- Special instructions, if any.

Transferring and transporting out of gauge cargo requires a team of experts who can plan and execute the handling and transport of such cargo from its point of origin to the destination.

Most leading shipping and transport companies have separate teams to handle OOG cargo consignments.

You might also like to read:

- Telex Release; Everything You Wanted to Know

- What Is CBM Rate In Shipping?

- What is Seaway Bill in Shipping?

- What is Non-Vessel Operating Common Carrier (NVOCC)?

- Voyage Charter vs Time Charter

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

Hari Menon is a Freelance writer with close to 20 years of professional experience in Logistics, Warehousing, Supply chain, and Contracts administration. An avid fitness freak, and bibliophile, he loves travelling too.

Latest Maritime law Articles You Would Like:

Latest News

- What is the Purpose of DG Shipping?

- What are Logistics Risks?

- How Port and Terminal Operators Can Control Emissions?

- Minimum Quantity Commitment (MQC) and Liquidated Damages in Container Shipping: Concept and Relevance

- MARPOL (The International Convention for Prevention of Marine Pollution For Ships): The Ultimate Guide

- The Ultimate Shipping Container Dimensions Guide

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.