What Are Open Top Containers – Design, Specifications and Dimensions

The global container shipping industry is worth billions of dollars. Compared to other goods and cargo ships, container vessels present a unique method of seaborne transportation.

Compact and easy to store, shipping containers are the best mode for efficient transportation across the world. Containers are built to allow nearly every type of cargo to be shipped.

Companies can hire units, store goods in any manner they wish, and then have it shipped around the globe.

Additionally, the way that these containers are manufactured ensures that several units can be stacked on top of each other. The container vessel allows for hundreds of containers to be stored onboard.

No other vessel is capable of transporting such a large variety of goods in a single voyage. For this reason, the annual growth rate of the container industry is on a steady increase.

Within the container industry itself, there are several different containers that can be commercially used for shipping. From wholly refrigerated units called reefers to custom made units for factory and industrial parts, there is a type of container for almost every single good that can be shipped.

An important point to keep in mind is that containers are generally of fixed dimensions. The height and breadth are consistent across most widely available units, while the length varies between either 20 foot or 40 foot.

These are the internationally accepted standards for shipping container sizes and are referred to by 2 unique names-

Twenty-Foot Equivalent (TEU) and Forty Foot Equivalent (FEU).

When measuring container traffic,

1 FEU = 2 TEUs

However, what happens when the cargo to be shipped is too tall for the container? Or it cannot be loaded through the doors at either end of the container? For such goods, cargo ships and general carriers may not be an option.

This is where the Open Top Container comes into picture. It is an important container unit that is provided by most shipping lines and logistics companies around the world. It offers enables several industries to function by allowing a larger variety of goods to be transported.

In this article, we will take a closer look at the Open Top Container, the goods commonly transported in such units, and the restrictions imposed on it.

Introduction to Open Top Containers

Open Top Containers (OTCs) are a type of container unit that is unique in structure. It is characterized by an open-top that is covered by a tarpaulin. It is specifically built to store large unwieldy cargo that cannot be transported by conventional containers. In addition to the open-top, it can also be accessed through doors on either end of the container that allows normal goods to go through.

Most containers are manufactured from steel to provide structural strength despite having a discontinuity at the top. Reinforcements run along all sides to keep the shape rigid and also to support loads from all directions.

The cover on top and the doors can be locked and are also sealed by the customs at a port. While other containers are difficult to tamper with due to the seal placed on the locks, there is an additional challenge of sealing open-top units.

For this reason, heavy-duty covers are used and are kept in place by clamp locks that cannot be unlocked without a special device. Additionally, these containers are monitored while in transit to prevent theft or vandalism to the unit.

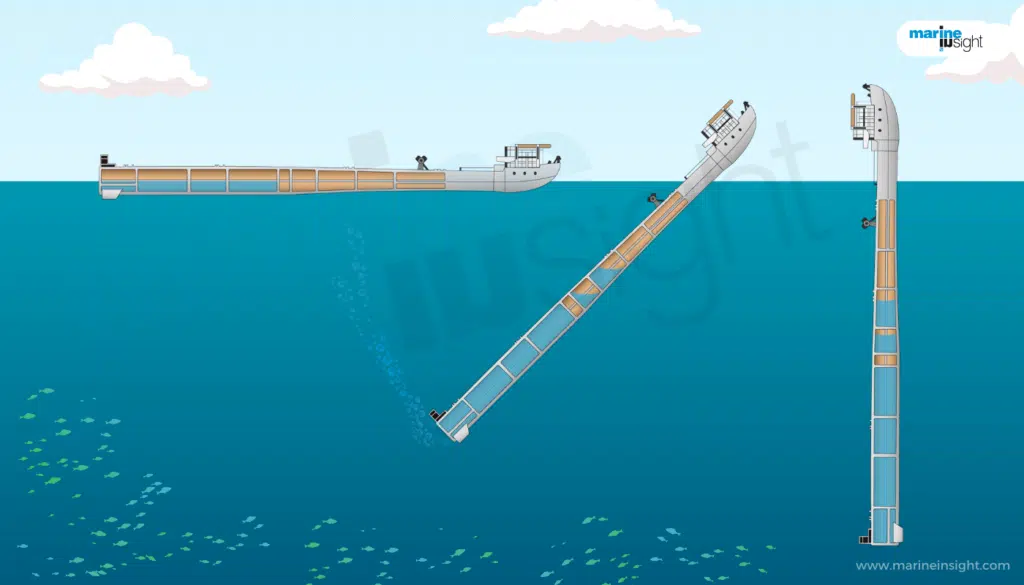

Loading and unloading operations are carried out in a manner similar to any normal container. Spreader cranes are used to lift the unit up while container stackers are used within the yard for arrangement.

In most cases, the cargo within fits well within the container dimensions, and so, the tarpaulin remains horizontal. In such cases, the container can be stacked under other units without any structural problems. However, if the cargo is large, bulky, and does not fit into the container, then some portion of it will stick above the container sides.

In such cases, the container cannot be stacked. During shipments, such container units are kept in a separate location to ensure that they are not damaged.

Similarly, at the container yard, open-top containers are placed in a different location to prevent accidental stacking. For moving OT units with cargo that sticks above the roof, only forklifts or vertical stacking cranes can be used.

Due to the novelty of OT containers, they are not easily available in the market. Shipping lines such as Maersk provide these facilities around the globe and even offer special services to keep your cargo safe and secure throughout the journey.

Due to the lower number of such units in circulation, they cost slightly higher than conventional containers. Also, the cost varies depending on the type of cargo you wish to transport. Cargo that stays entirely within the unit is typically charged much lesser compared to cargo that extends beyond the roof cover.

Open Top Container Specifications and Dimensions

Due to the specialized nature of goods shipped in OT containers, the dimensions play a very important role when selecting a unit. Broadly speaking, OT units are classified into 2 sizes- twenty-foot and forty-foot units. Within these, there may be standard and high cube containers that can store larger goods.

The 20-foot unit weighs between 2,000 to 4,000 kilograms in an unladen condition, referred to as the “Tare Weight”. It can handle payloads near 30,000 kilograms and has an internal volume of less than 35 cubic meters.

The 40-foot unit weighs 3,850 kilograms in an unladen condition, also has a maximum payload in the region of 30,000 kilograms, and has an internal volume of 66.4 cubic meters.

Note, the volume capacity is double that of the 20’ equivalent, while the weight only increases marginally. This is due to the decreasing strength of the container as the length increases.

Despite being 2 times longer, the container now has a higher chance of bending under stress and suffering from fatigue-related failure. So, the payload capacity is not proportionately increased, unlike the volume capacity.

Some of the major dimensions of a 20’ and 40’ open top container are given below:

20 Foot Container 40 Foot Container

| 20 Foot Container | 40 Foot Container | |

| INTERNAL LENGTH | 5.89 m | 12.03 m |

| INTERNAL WIDTH | 2.35 m | 2.35 m |

| INTERNAL HEIGHT | 2.38 m | 2.38 m |

| EXTERNAL LENGTH | 6.06 m | 12.19 m |

| EXTERNAL WIDTH | 2.44 m | 2.44 m |

| EXTERNAL HEIGHT | 2.59 m | 2.59 m |

| UNLADEN WEIGHT (TARE) | 2,260 kg | 3,720 kg |

| PAYLOAD CAPACITY | 31,260 kg | 28,780 kg |

| VOLUME CAPACITY | 32.7 m3 | 66.7 m3 |

| ROOF OPENING LENGTH | 5.44 m | 11.57 m |

| ROOF OPENING WIDTH | 2.23 m | 2.21 m |

| DOOR OPENING WIDTH | 2.34 m | 2.34 m |

| DOOR OPENING HEIGHT | 2.28 m | 2.29 m |

It is important to note that the exact dimensions may vary between container manufacturing companies.

Common Cargo and Goods Shipped in Open Top Containers

Some of the common goods carried in open-top containers include machinery and factory parts such as pipes, heavy-duty tires (such as those for heavy lift vehicles), jet and ship engines etc.

From the previous section, we see that the unit can bear weights up to nearly 3 tons. Most types of cargo fall well within this limit but are selected for shipment by OT containers due to their unwieldy shape. In this section, we will look at the types of goods and provide some guidelines to help you decide if your cargo classifies as an open-top cargo.

OT containers behave differently under loads as compared to other conventional units. They are widely used across the industry even till date. There are primarily 2 types of cargo that may be shipped in an open-top container.

First, the cargo may be so large that it cannot fit into a conventional TEU or FEU. In such cases, a crane will hoist the entire cargo through the open top into the container. It will then be restrained using tethers provided along the walls and floor of the unit.

Specially built pad-eyes and lashing rings that are capable of motion restriction are used for this purpose. These can generally resist loads up to 1,000 kilograms. Once the structure is in place, a tarpaulin or other suitable cover is placed over it and secured into place. A little slack is provided to prevent the transfer of shocks or jolts during shipment. Such types of cargo are most common when using open-top units.

Second, while the cargo may fit within the dimensional constraints of a TEU or FEU, it may not be possible to load it through the container doors. This could be due to its fragile nature, the lack of rollers on the container floor, or some other issue.

Certain containers are built for such eventualities where rollers enable the cargo to be pushed safely into the container. However, fragile and bulky structures may not work well with rollers.

Additionally, they need a flat surface to be able to move across the floor. These challenges make it difficult to use standard containers. For this purpose, an open-top container is perfect. Here, the tarpaulin is completely secured to the top of the container under tension. Tethers and restraints keep the cargo in position throughout the voyage.

How to Choose the Right Open Top Container

Picking the right container is extremely important and this extends to OT containers. Open top units allow for a wide range of goods to be shipped as we have discussed above. However, there are several key points to be considered when selecting such a unit. One must account for the structural safety and the services provided. Reputed logistics and shipping companies freely provide all customers with such details. This allows you to make an informed decision on which container unit to pick.

The open-top container is a structurally critical unit. Conventional containers that are closed on all sides are stiffened with reinforcement members. This keeps the structure rigid and enables it to withstand forces in most directions.

Such structural strength is important for containers since they are often stacked on top of each other and must bear large loads. However, even with the extra reinforcement, when loads that exceed the permissible limits are applied, a container may buckle or bend. So, what happens if you take the top of the container? The structural integrity is severely compromised in such a situation and adequate measures have to be taken.

The load can no longer rest on the top since it is covered with a tarpaulin that cannot bear loads. For this purpose, the loads are transferred downwards using container supports that run along the four vertical edges of the container. In addition, since open-top units are weaker, there are additional vertical supports running along the side faces as well.

The sides of the container are made stronger and stiffer by adding materials with higher yield strength. So, when picking up an open-top container, you must ensure that it is structurally stable while keeping in mind that it lacks a strong roof for support.

Next, when selecting an open-top unit, there are a few points to keep in mind about external services provided. Sometimes, padding or other substances have to be placed to secure fragile types of cargo. In such cases, some logistics companies provide the necessary padding or may even custom make polyester cases to hold the cargo.

The tarpaulin cover that is also provided with the unit may need to be modified to suit your need. For example, it can be secured by different methods such as a knotted arrangement (where it is connected to the mainframe by a series of knots), clamped arrangement (where it is clamped between the side plates of the container), or a crank-belt mechanism (which is capable of applying tension to automatically tighten and secure the tarpaulin).

In almost all cases, the cargo may simply have to be top loaded, and this is the reason for picking an open-top container. Then, the tarpaulin will be placed under tension along the roof of the unit. However, if a portion of the cargo sticks out of the unit, safety precautions may have to be taken to allow the tarpaulin to move with some slack. This prevents the loads exerted on it from transferring to the cargo and potentially damaging it.

You may also like to read – What Are Supramax Cargo Vessels?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Type Of Ships Articles You Would Like:

About Author

Ajay Menon is a graduate of the Indian Institute of Technology, Kharagpur, with an integrated major in Ocean Engineering and Naval Architecture. Besides writing, he balances chess and works out tunes on his keyboard during his free time.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.