20 Hazards On Oil Tanker Ship Every Seafarer Must Know

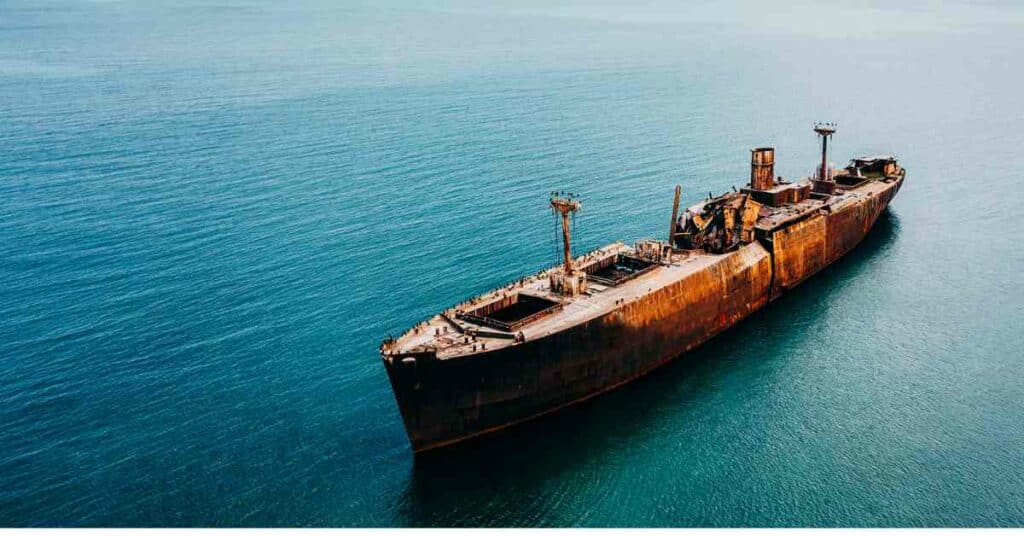

The world runs on oil and so do the ships which transport this oil around the world. The ships that are used for transportation of liquefied cargo in bulk are popularly known as tanker ships. Out of all tanker vessels sailing at sea, the most extensively used is the oil tanker ship.

Oil Tankers can be broadly classified into two types:

Crude oil tanker ship: These types of vessels are bigger in size; e.g. VLCC tanker or ULCC tanker and are used to carry a large amount of unrefined crude oil from one port to another. They mainly transfer the unrefined product from the source to the refineries.

Product tanker ship: This type of vessel is mainly used to transport refined oil. They are smaller in size as compared to crude oil tankers.

Related Reading: Different Types Of Tankers

Considering the hazardous nature of the cargo these types of vessels carry, a seafarer working on an oil tanker ship has to be extra vigilant and also need more extensive safety training as compared to that for a dry ship (container or bulk carrier ship). Not all cargo carried by different types of tanker ships is dangerous, but all of them have some risks involved.

Needless to say, it’s of extreme importance that seafarers who are working on any type of tanker ship, whether VLCCs or ULCCs tanker or a small product tanker, must acknowledge and validate various occupational risks involved on a tanker ship.

Listed below are 20 hazards related to an oil tanker ship which a seafarer must be aware of:

Flammability:

1. Cargo: Cargoes carried on tanker ships are flammable in nature as most of them release some types of gases which may form a combustible mixture composed of hydrocarbons. A flammable mixture contains 1 – 10% hydrocarbon gas by volume and the rest is air.

2. Smoking: Several incidents of fire in the past have occurred because of smoking in prohibited areas. A seafarer must always follow all the instructions on smoking and should smoke only in the designated areas where it is permitted. Avoid taking cigarettes, matches or lighters out on the deck. (Note- As we write this, most of the shipping companies have prohibited smoking on their vessels.)

Static electricity:

3. Static electricity charge in the tank: On an oil tanker, this phenomenon might not be that dangerous as electricity is earthed to the ship’s hull. However, in case a charge remains in the tank, a metal object brought into the tank may generate a spark, resulting in an explosion. Thus, always check for earthing before taking any metal object, tools, or sounding tape inside a tank.

4. Steam: Steam should not be injected into a compartment or piping system which contains a flammable mixture, as high-velocity water droplets in a jet of steam may become charged while passing through a nozzle and can produce a charged mist.

5. CO2: The fixed CO2 fire fighting system is installed to suppress the fire by spraying CO2 at high velocity. It will rapidly evaporate, and then cool and form particles of solid carbon dioxide, which may become electrostatically charged.

Related Reading: 30 Ways To Make Cargo Operation on Tankers Safer

Personal Equipment Hazards:

6. Unapproved Torches: It is common practice among seafarers to carry their own torches when joining a new vessel. In an oil tanker ship, only EEX-approved flashlights are to be used at all times.

7. Mobile Phones/ Camera: Never carry a personal GSM mobile phone, camera and other similar equipment to open deck as they may cause sparks and ignite any flammable gas.

Related Reading: Why Are Intrinsically Safe Cameras Used On Tanker Ships?

Tools:

8. Unapproved power tool: Electrical equipment and power tools are widely used in daily ship operations. In oil tanker ships, use only intrinsically safe electrical equipment at all times.

9. Hand tool: Metal tools are a common source of spark if they fall or come in contact with another tool, deck surface or any other metal surface. Use such tools only in the safe area (such as the open deck) after inspected by a responsible officer.

Non-sparking tools are available but they can be hazardous as ferrous metals (which can cause sparks) might be embedded in the material. All non-sparking tools on the ship must be inspected for any hard substances embedded in the softer non-ferrous material.

Aluminium:

10. Aluminium Equipment/ tools: Aluminium metal against a rusty surface leads to increase in the temperature of the surface. Avoid using equipment and tools made out of aluminium in hazardous areas. In the galley, aluminium utensils (e.g. ladle or spade) should not be used.

11. Aluminium Paint: Similarly, aluminium paint will have the same effect as explained above on a rusty surface when another metal is rubbed or banged on it.

Cathode protection unit:

12. Anodes: Anodes are installed inside tanks of a tanker ship to avoid corrosion. Never drop or let the anode hit the tank surface as it may create a spark – a source of ignition for flammable gases.

Related Reading: Understanding Sacrificial Anodes On Ships

Harmful mixture:

13. Inert gas: Inert gas is considered as the main source to prevent fire on an oil tanker ship. It is, however, harmful to the humans when inhaled. A poor quality inert gas, having high CO2 content, can react with ammonia, causing carbamate formation

14. H2S: Hydrogen sulphide usually is present in crude oil, naphtha, fuel oil and gas oils. Its concentrations are generally lowered before loading it on a tanker vessel with unique stabilisation methods. Still, even a small amount of H2S can be highly toxic, corrosive and flammable at low levels. It is colourless gas with a smell of rotten eggs. Exposure to high levels of H2S can be fatal even for a very brief period of time.

15. Corrosivity: Crude oil carried in a ULCC tanker or petrol in a product tanker are pre-treated to remove the salts such as chlorides of calcium, magnesium and sodium, and other impurities that are corrosive. If present, these salt will react and release harmful liquid or gases which may attack human tissue.

Related Reading: 7 Dangerous Diseases / Disorders Seafarers Must Know

Weather:

16. Wind: Wind speed plays an important factor in safe cargo operation on an oil tanker ship. If the wind speed is very low or nil, the vapours released or purged will not disperse and persist on deck, resulting in a flammable situation.

Also, a strong wind may create low pressure on the lee side of a deckhouse or structure and thereby cause vapour to be carried towards it.

The responsible officer of the tanker ship must take a call to carry out the cargo operation in such situations.

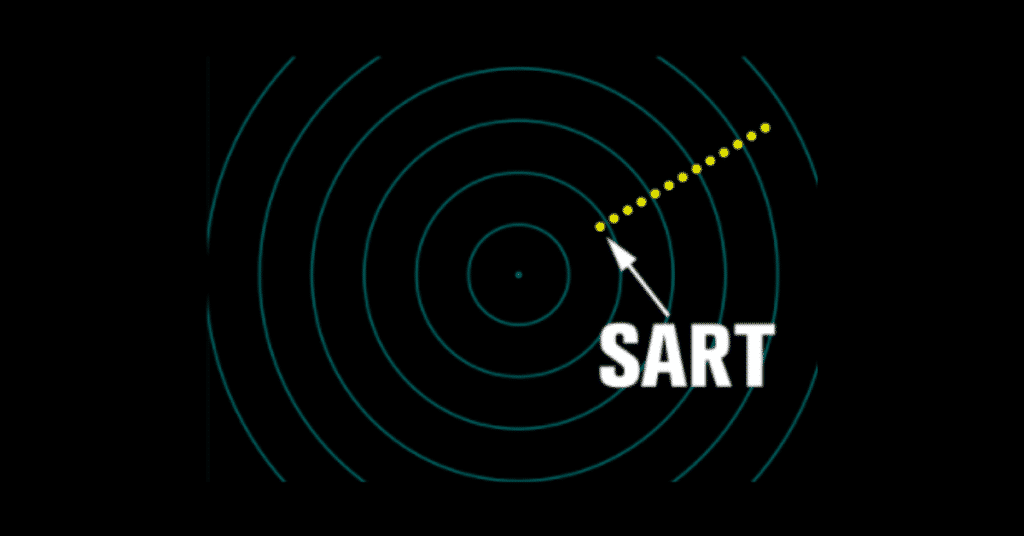

17. Lightning: If there is an electrical storm in the vicinity of the ship, the cargo operations must be stopped immediately.

Related Reading: 7 Important Points For Safe Lightering Operations On Ship

Oxygen deficiency:

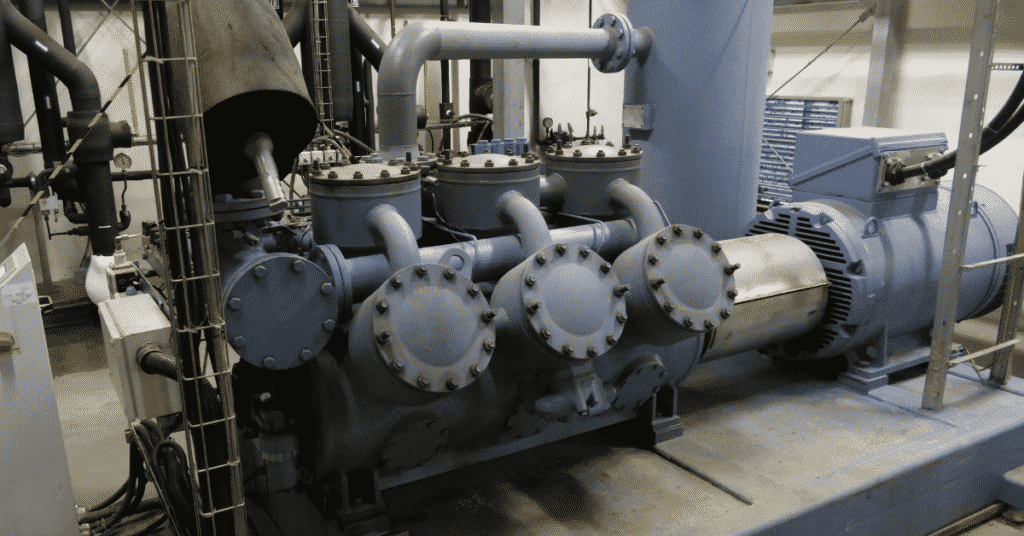

18. Enclosed space: Ther are several enclosed spaces on ships, and the number increases further for an oil tanker ship. Pumproom of a tanker ship is considered to be an enclosed area, and all entry precaution must be taken by the seafarers before entering, as it is one of the most frequently visited confined space.

Needless to say, for tanker cleaning or inspection, all the enclosed space precautions must be taken by the crew.

Related Reading: Procedure For Entering Enclosed Space On Ships

Repair work:

19. Hot work: Hot work is considered to be one of the most dangerous operations on a ship, and when it comes to a tanker ship, the hazardous level increases drastically. Seafarers conducting the operation not only have to follow all the precautions on the location (by ensuring no hazardous environment) and adjacent places but also have to ensure the wires used for equipment used on ships do not pass through flammable areas and are intrinsically safe.

Under hot work, all operations such as gas cutting, sandblasting, electrical arc welding and use of spark generating tools are included.

No hot work must be undertaken inside a compartment until it has been cleaned and ventilated. The atmosphere tests in the chamber should indicate 21% oxygen content by volume, not more than 1% LFL, and must be free from toxic gases. It is essential to continue ventilation during the operation.

Related Reading: 20 Practical Tips For Safe Gas Welding and Cutting Operations On Ships

Pollution:

20. Spillage: Oil Spill hazard is not precisely related to the tanker ship only, but it can majorly affect the marine environment near the vessel. History shows that almost all major pollution at sea were a result of accidents on tanker ships.

You may also like to read – What is Ship Arrestor Technology?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Ship Safety Articles You Would Like:

Latest Shipboard Guidelines Articles You Would Like:

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

well-ship’s are dangerous, not my own ship but have the situations as a cadet, nobody talk’s ” it is a hidden, secret “ban

any mild/carbon steel

best regards / [retd] capt.salim a chagla

Good article for basic knowledge on tanker ships. Could I share it with our crew vessel?

Many thanks.

Rgds,

Imam H. Elhaq

Excellent Article For Tanker Man !! This Article Train Our Brain Regarding Basic Tanker Safety !!

Thanks for such an informative blog. Like it a lot. To prevent from accidents explosion proof camera also help us.

Really helpful for my physics homework.thnx mate

??

How safe it is to do Chipping and grinding on Tanker vessel if Naftha is loaded on board

Crude oil ships may the crew face time thier family or use hangout google video to chat with family or phone calls or WhatsApp video

If this is hazardous please explain