How and Why to Take Manual Sounding On Ship?

Sounding is a term used for taking a measurement of the amount of fluids in the tanks of a ship. Different type of sounding methods are used on board ships. In this article, we will take a look at the importance of taking manual sounding and the method of taking the same.

Why Manual Sounding?

On board ship, it is very important to keep the updated record of the quantity of liquids (in all forms) present in various tanks. A ship is fitted with different types of automatic and hydraulic/ pneumatic/ mechanical sounding measuring systems wherein the level of the liquid can be checked remotely or locally without manually measuring and calculating the liquid amount inside the tank.

One cannot entirely depend on the automation and mechanical devices, especially when it comes to those substances, for which, negligence can cause oil pollution and machinery damages. Manual sounding is always preferred by all seafarers (deck and engine crew/ officer) to recheck the level of the fluid in the tanks, ensuring the tanks will not overflow or run dry in any case.

When to Take Manual Sounding?

Manual sounding is taken by ship’s staff on a daily basis, but the following are the operations and situations wherein the crew has to take manual sounding without fail:

- On a daily basis to check the level of all ship’s tanks

- When Oil transfer operation is going on, for e.g bunkering, sludge or bilge transfer etc.

- When fresh water is received from the port

- When OWS is operated, bilge tank sounding is monitored manually

- When ship is involved in grounding or collision, the ship officer from each department must check all the tank sounding to assess for any leakages

- When chief engineer is relieved by the new chief, he/she should check the actual level and oil quantity present onboard by manually sounding all the tanks

- Before the ship is reaching a port, all important oil tanks are sounded and quantity cross checked with sounding records for making the cargo plan

- When ship is going to a dry dock for making the docking plan

- When ship is entering Special Areas under MARPOL Annex VI and where fuel quality change is required

- Ballast tank sounding before approaching port, canal, channel etc.

Tools Used For Manual Sounding

Basic tools and things used for manual sounding:

Sounding Tape

For manual measurement of sounding, a measuring tape normally made up of brass and steel with a weighted bob attached at the end of the tape using a strap hook. Sounding Tape comes in meter or feet metric with bob is mostly of cylindrical shape and Torpedo shape. Torpedo (Dip-weight in the form of a rod, terminating in a truncated cone at the lower end) shape is more commonly used for thicker liquid as the cone penetrates the oil/sludge more easily.

A stainless steel tip on the brass dip-weight prevents wear down. Cylindrical bob is used for sounding of water and diesel/ lube oil and similar fluids where penetration is easy to achieve.

The graduation in mm. continues on one flat side of the dip-weight to eliminate any blind spot where the tape is connected to the weight.

Stainless steel dip-weights are intended to use with stainless steel tapes. Brass dip weights are to be used with carbon steel and polyamide coated tapes.

Generally, the dip weights available for measuring water and similar fluids is approx. 400 gram. Bob weight of 700 gram to 1000 grams are most common one for oils and fats.

Water / Oil Finding Paste

These are special pastes which are applied on the sounding tape. They are normally available for water sounding and gasoline/diesel oil sounding as they are transparent in color and difficult to detect in the measuring tape. The paste is applied on the sounding tape and when it comes in contact with the water or gas oil, it will change it’s color, indicating the level.

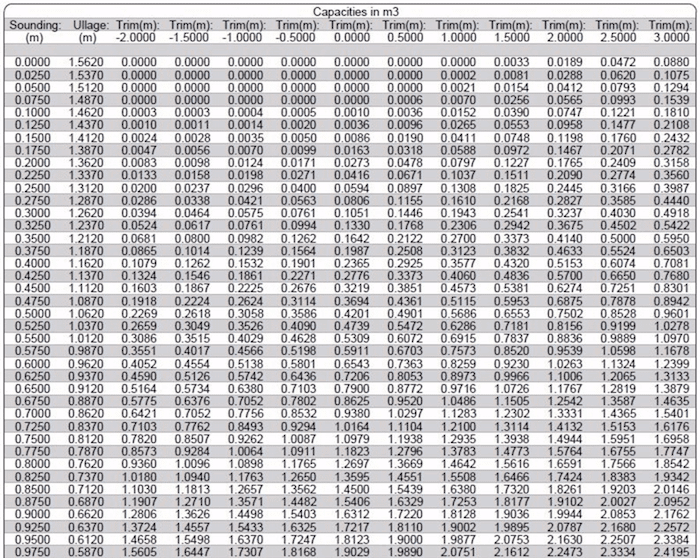

Sounding Table

Sounding table is a chart describing the construction, capacity and most importantly the volumetric content of the tank at given depth of sounding or ullage. All vessels have their own sounding table documents for each tank containing fluid in bulk. The sounding table is compiled to show the volumetric quantity of fluid at various trims and list for the particular sounding depth in cm.

How to take Manual Sounding?

There are two methods to measure the level of the tank:

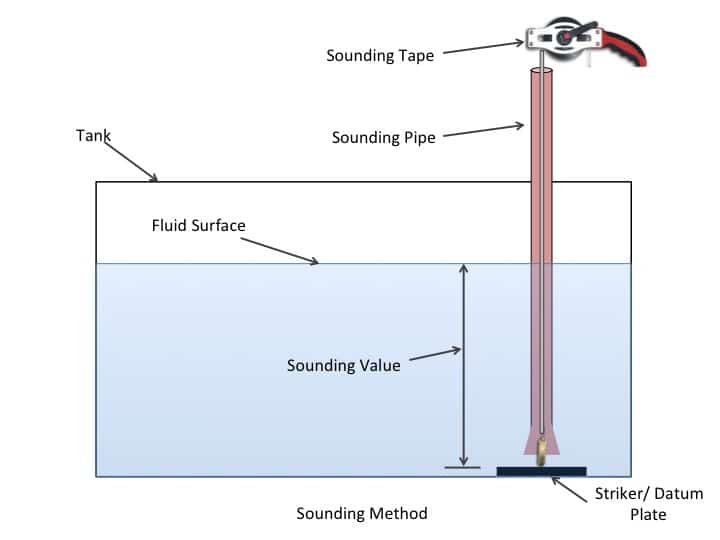

1. Measuring level by sounding the tank

In this method, the sounding tape is inserted in the sounding pipe and bob is lowered till it touches the bottom of the tank i.e. the datum plate (check figure). The tape will measure the complete depth of the liquid which will be compared to the sounding value in the sounding table.

For e.g. Tape is rolled inside the tank till the bob touches the tank bottom. If the tape measure 1000 cm – check the list or trim of the ship and compare the volumetric value for the sounding depth of 1000 cm.

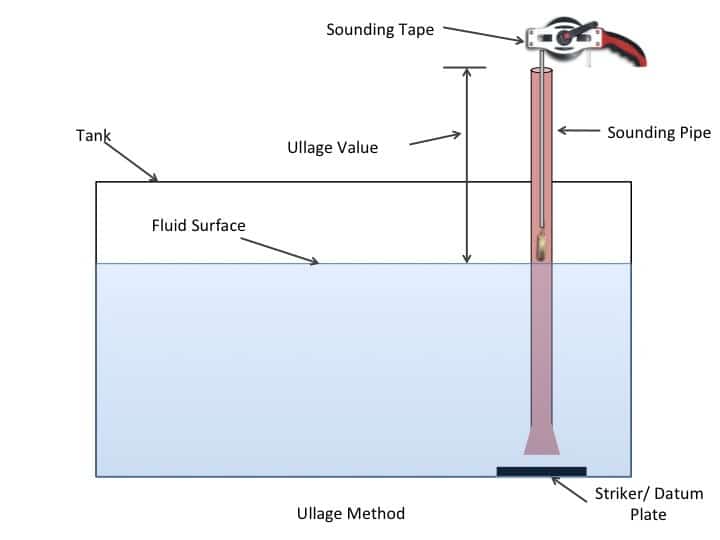

2. Measuring level by calculating the Ullage of the tank

When measuring level by ullage method, the sounding tape is inserted only till the bob/ tape touches some part of the fluid top surface. Instead of measuring the whole depth of the tank, only the free space (from the top of sounding pipe to liquid surface) is measured (Check Figure). This method is convenient if the fluid in the tank is at a higher level. In heavy oil tanks and viscous fluids, this method does not spoil the whole sounding tape and avoids a false reading.

For e.g. If the sounding tape is lowered till 500 cm and the tape measures oil in the tape as 100 cm. The total depth of the sounding pipe is 1600 cm. Hence the ullage is: 500cm- 100cm= 400cm, and sounding value can be calculated as

1600 – 500 +100 = 1200 cm.

Normally ullage values are also provided in the sounding table with reference to the trim of the ship to get the volumetric content in the tank.

Follow the steps mentioned below to take sounding on a ship using the sounding tape:

1) Make sure the bob is tightly held with the tape using a strap hook. Ensure that the tape is not damaged anywhere in between to avoid dropping of bob or tape inside the pipe

2) Know the last reading of the tank in order to have a rough idea whether to take sounding or ullage

3) Apply water/ oil finding paste to get exact readings (for Water and gas oil)

4) Drop the tape inside the pipe and make sure it strikes the striker plate

5) Coil up the tape and check for impression of paste and then note the sounding

6) Check the trim and list of the ship to read the correct reading for volumetric content of the ship

7) Note down the sounding in the record book with signature of the officer in charge

Basic Maintenance of Sounding tape

To avoid wear of the sounding tapes, following points to be taken care of:

- Ensure to clean sounding tape after each use, especially post heavy oil / viscous fluid tank measurement

- Sounding tape to be stowed in it’s drum after cleaning. Tangled or unrolled sounding tape edges tends to wear at a faster rate which may eventually break

- Check the strap hook for its tightness to avoid loosing of bob inside the tank. An additional wire can be used to tie the tape and hook (depending upon the oil/ cargo it will be used for)

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

dear sir , i have a qustion to you, d.o servicetk drain valve chocked , how to repair and what is your action?

For ullage method, how do we know when to stop lowering the tape?

@Ibrahim : You should know the last recorded sounding value and if the concerned tank content is under consumption, an approximate value of oil consumed.

Can you please put sources to regulations on these.

Why do we take soundings daily in terms of Law?

Hi Dennis,

Thank You for the pointed correction. Appreciate your support.

my questions: 1

how to prevent damage to the bottom tank by the use of sounding tape.

*question* 2

how to prevent flooding of a ship through sounding pipes that do not terminate above the main deck?

@Vincent:

1. A striker plate (As shown in the diagram) is used to avoid damage to the tank bottom

2. for the double bottom tanks whose pipe opening is not above the main deck: it has to be fitted with self-closing cocks.

I do not understand why you cannot trust the gauging system. However there are three reasons why you cannot trust the sounding system.

1. Incorrect selection of the gauging system

2. Incorrect installation of the gauging system\

3. Incorrect maintenance of the gauging system (no records of calibration)

If all the above is completed it is a reliable means to perform effective operations. Also it will reduce your man power as taking sounding on a daily basis as suggested consumes resources which is money.

what r the reasons for preferring ullage method rather than dip method in vessels??

We have explained this method (and its advantage)in this article – https://www.marineinsight.com/guidelines/sounding-and-different-methods-of-taking-sounding-on-a-ship/