List of Important and Not-So-Famous Tanks on a Ship

Fuel oil, diesel oil, and lubricating oil tanks are the names of tanks everyone is aware of. But there are several tanks apart from them which also play an important part in the overall working of the ship. Moreover, there are also tanks of which many people are not aware of. In this article we will have a look at some important and some not-so-famous tanks present on the ship.

Hydraulic Oil Tanks

Hydraulic oil tanks for valves

Separate tanks are used to store oil which is used for different valves on the ship. Valves such as ballast valves, fuel valves etc. are remotely operated by hydraulic oil.

Hydraulic oil tanks for Winches

Tanks for hydraulic oil are located outside the engine room to store winches oil.

Hydraulic oil tanks for Steering gear

Steering gear hydraulic oil tank is normally located in the steering room and is used as a storage tank to receive bulk oil.

Water tanks

Fresh water tanks

Fresh water tanks present onboard may be two or more in numbers, depending upon the size of vessel. They are used to store sanitary water for accommodation, engine room and deck use.

Drinking water tank

A separate drinking water tank may be present to store drinkable water received from shore or to store water produced by fresh water generator (F.W.G).

Distilled Feed water tank

A ship’s boiler needs distilled water to produce steam, and therefore water from fresh water generator (F.W.G) is stored in distilled water tank.

Boiler feed water tank

The boiler feed water system consist of a separate tank which receives water from distilled water tank.

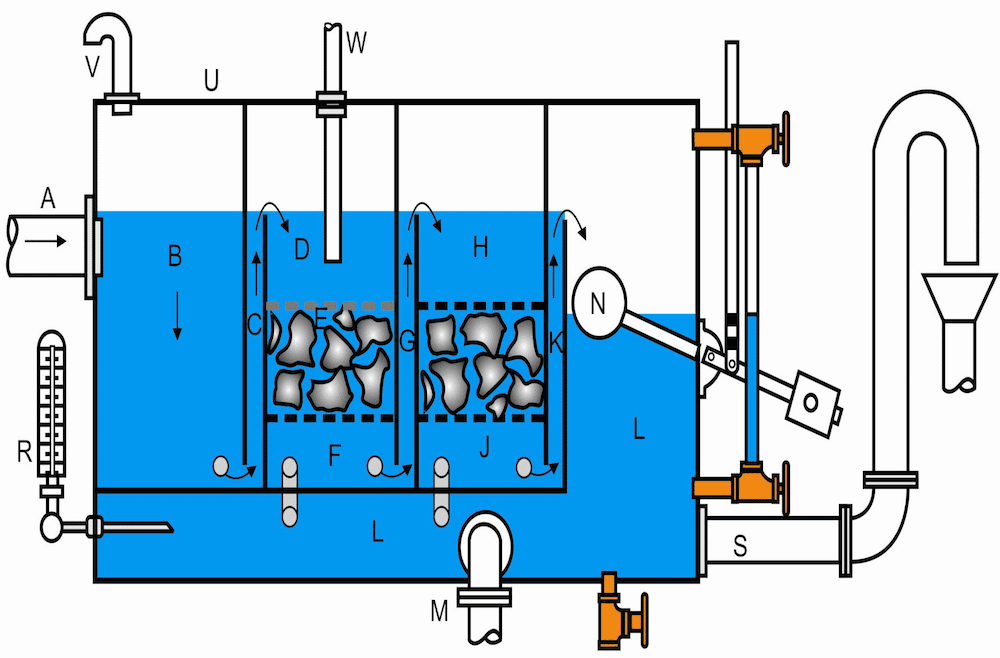

Cascade tank

Cascade tank, also known as hot well, is a part of boiler feed water system. Water is pumped into the cascade tank from the feed water tank. The boiler water is treated in the cascade tank and the return from the steam heating system is also connected to the hot well.

Ballast water tanks

Ballast water tanks are present all over the ship for ballasting and de-ballasting purpose for stabilizing the ship and for acquiring correct draught for port and canal crossing etc. Double bottom tanks are generally located outside the engine room.

Stern tube cooling water tank

This tank is located around the stern tube of the propeller and acts as a cooling media for the same. It can be used as a fresh water water tank of the ship.

Slop tanks

Slop tank in tanker

Slop tanks are present onboard tanker to store oily water mixture from cargo tank washing. The number of slop tanks depends on the Dead weight Tonnage (DWT) of the vessel.

Sludge tank

Located in engine room, this tank is used to store sludge produced after treating fuel or lube oil through purifiers.

Bilge tank

The water and oil leakage in the engine room is collected in bilge wells and this oily water mixture is then transferred to primary bilge tank or bilge holding tank, where the mixture is settled down and then is transferred to secondary bilge tank.

The oily water separator is supplied through secondary or separated bilge tank and a shore connection is also connected to this tank to dispose off all the collected bilge to shore.

Scavenge drain tank

The sludge produced by the main engine in the scavenge area is collected in the small capacity scavenge drain tank.

Oily Water Separator (O.W.S) Sludge tank

When oily water separator operates, it separates oil from water and that oil is collected and discharged into a separate tank known as O.W.S sludge tank.

Other Not-So-Famous yet Important Tanks

Drain tank

The drain tank is located in the engine room. All drip trays and other drains are connected to this tank.

Leak off tank

This is a small tank separately fitted in the main engine and all auxiliary engines to detect any fuel leakage. The tank consists of an orifice and a float. If the leak is very small, it will pass through the orifice; but if leakage increases, the oil will not be able to pass through the orifice and tank level would increase, rising the float and thus giving an alarm.

Stuffing Box Tank

The main engine stuffing box scraps the impure lubricating oil, which is collected in a separate tank known as stuffing box tank.

Stern tube gravity tank

The stern tube system oil is circulated in the system by means of two tanks, lower gravity and upper gravity tanks.

Waste oil tank

The waste oil tank is a separate tank used to collect waste and impure oil produced onboard ship.

Soot collecting tank

When the economiser tube washing is done, the soot water is collected in a soot collecting tank.

Sewage holding tank

The sewage produced from the onboard crew is collected in a common tank known as sewage collecting tank. The sewage plant takes intake from the sewage holding tank.

Expansion tanks

The jacket water system of main engine, auxiliary engine and some times main air compressor are provided with individual expansion to provide provision to compensate change in volume and maintaining positive pressure.

Jacket water drain tank

When any maintenance is to be done on the main engine, the jacket water is drained and collected into the jacket water drain tank.

Rocker arm tank

Many diesel generators are provided with separate rocker arm lubricating oil tank to avoid contamination.

You may also like to read Fresh Water Generator & Ballast Water Management plan

Image Credits:

norherntool

chazsworld

ssmaritime

nauticexpo

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

List is good, but stern tube cooling water tank is forgotten and may be considered as No1 Not-So-Famous yet Important Tank.

Thanks for your valuable suggestion. The tank has been added in the list.

very useful knowledge . thanks a lot

Hi Anish

Very interesting article. I do have a question about the function of a cascade tank.

1) Is this the same tank where the wasted steam from the heating coils for fuel oil storage tanks is condensed into the cascade tank?

2) also if any heating coils are damaged or leaking it would contaminate the cascade tank by the oil entering into the cascade tank and vice versa that is water from the cascade tank will enter the fuel storage tanks through the heating coils thus in turn contaminating the fuel oil

thanks for your assistance

Johsie

3)

@ Joshie:

1. Yes. The return steam (wasted steam) is condensed and sent back to cascade tank.

2. Yes, if their is oil leakage in a heating coil it will come into cascade tank. Cascade tank is provided with an observation glass with a light lit at the background to detect floating impurities and oil contamination since oil having lighter density will float up. The suction of the boiler feed water pump which supplies water to boiler drum is taken from the bottom of the cascade tank to ensure less oil goes to boiler, if the tank gets contaminated. Now a days cascade tank is provided with continually measuring oil detecting device and filters to absorbs small oil quantity.

You can also post your questions in our forum to get multiple and speedy replies: https://forums.marineinsight.com

Thanks very much!

@ Anish:

Hi Anish – During gauging of FO tanks I have come across a similar situation where the C/E told me that # 2 FO Tank (Storage Tank) was contaminated with water and is thus unusable.

Reading the above discussions that would mean that in case of rupture of the heating coils the return steam line would carry with it oil from the storage tank into the cascade tank but how does the water enter the storage tank? I presume the leaking steam coils will be releasing steam (condensing to water) into the storage tank? Am I correct in saying that and if so then 2 things would happen:

a) Steam consumption will increase because the steam is being ‘wasted’ into the storage tank (instead of heating the oil)

b) FW consumption will increase because the Cascade Tank level will continuously decrease and so regular top-up would be required (this was also reported by the C/E that water level in the cascade tank was decreasing)

Meaning to say that if steam consumption increases or FW consumption increases then this would be a sign that heating coils may have been damaged?

Thanks/kc

@ KC : If the heating lines are at higher pressure than the content they are heating (here oil), steam will leak out of the coil to low pressure system. The level (in this case- “head”) of the concerned bunker tank will be less to suppress the steam pressure causing the leakage.

a) Steam consumption will definitely increase as it is leaking out of the closed system.

b) Increase in F.W consumption is not a sure shot troubleshooting for steam leakage unless the fresh water tank is only used for boiler cascade tank filling. Increase in F.W consumption can be due to several other reasons as F.W is supplied to various machinery and to accommodation. The rate of fall of cascade tank level can be used as a reference for steam leakage.

Thanks very much!

Tou forgot rsw fish tanks as used on pelagic vessels

Dear Anish, I used to be a marine engineer some 20years ago. Can you provide me a typical design of cascade tank on board.

Regards

what are individual function of upper and lower header tank of stern tube

header thank.

To maintain the lubrication system for ships with variable draught (due to loading and unloading of cargo), header tanks are provided at around 2 to 3 meters above the water line so that the differential pressure ensures no water ingress.

Why cascade tank have divisions ?

Hi anish, excellent information. I am non marine person but recently came across that slops and sludge discharged from ship can be sold to petro chemicals. Is it true?