Converting Seawater to Freshwater on a Ship: Fresh Water Generator Explained

Fresh water generator, one of the important machinery on board a ship, is something that cannot be done without. Fresh water produced from fresh water generator is used for drinking, cooking, washing and even running other important machinery which use fresh water as a cooling medium.

Fresh water is generally produced on board using the evaporation method. There are two things that are available in plenty on ship to produce fresh water –Seawater and heat. Thus fresh water is produced by evaporating sea water using heat from any of the heat source. The evaporated sea water is then again cooled by the sea water and the cycle repeats.

Generally the heat source available is taken from the main engine jacket water, which is used for cooling the main engine components such as cylinder head, liner etc. The temperature available from this jacket water is about 70 deg. centigrade. But at this temperature the evaporation of water is not possible as we all know that the evaporation of water takes place at 100 deg centigrade under atmospheric pressure.

Thus in order to produce fresh water at 70 degrees we need to reduce the atmospheric pressure, which is done by creating a vacuum inside the chamber where the evaporation is taking place. Also, as a result of the vacuum the cooling of the evaporated sea water will also take place at lower temperature. This cooled water is collected and transferred to the tank.

Nowadays, reverse osmosis is one of the methods which are used on board for generating fresh water. Generally this is used on passenger vessels wherein there is a large requirement of fresh water production. However, in merchant ships the evaporation method is used as reverse osmosis is costly and includes large maintenance cost for membrane.

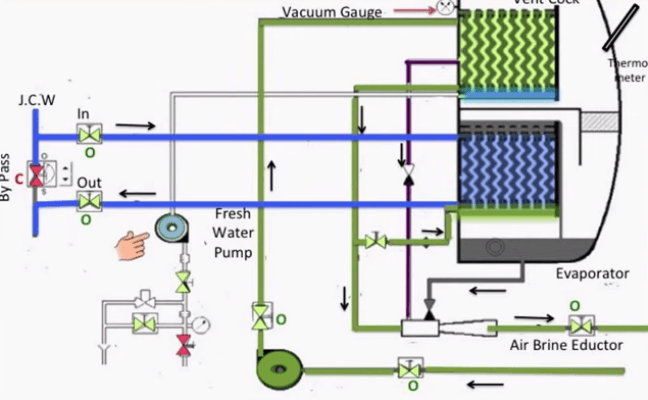

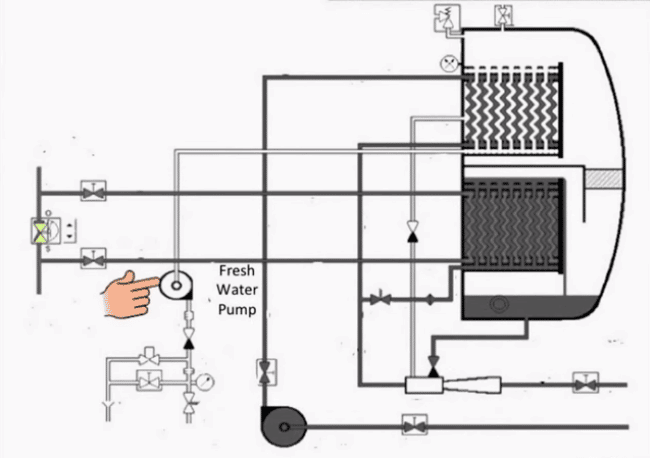

Fresh Water Generator Arrangement

The main body of a fresh water generator on the ship consists of a large cylindrical body with two compartments. One of the compartments is the condenser and the other is the evaporator. The fresh water generator also consists of an educator which helps in generating the required vacuum. The fresh water pump and ejector pump helps in transfer of water to and from the fresh water generator.

Starting the Fresh Water Generator

- Before starting the fresh water generator we have to check that the ship is not in congested water, canals and is 20 nautical miles away from the shore. This is done because near the shore the effluents from factories and sewage are discharged into the sea can get into the fresh water generator.

- Check whether engine is running above 50 rpm, the reason for this is that at low rpm the temperature of jacket water which is around 60 degrees and not sufficient for evaporation of water.

- Check the drain valve present at the bottom of the generator is in close position.

- Now open suction and discharge valves of the sea water pump which will provide water for evaporation, cooling and to the eductor for creating vacuum.

- Open the sea water discharge valve from where the water is sent back to the sea after circulating inside the fresh water generator.

- Close the vacuum valve situated on top of the generator.

- Now start the sea water pump and check the pressure of the pump. The pressure is generally 3-4 bars.

- Wait for the vacuum to build up. Vacuum should be at least 90% which can be seen on the gauge present on the generator. Generally the time taken for the generation of vacuum is about 10 minutes.

- When vacuum is achieved open the valve for feed water treatment, this is to prevent scale formation inside the plates.

- Now open hot water (jacket water) inlet and outlet valves slowly to about half. Always open the outlet valve first and then inlet valve. Slowly start to increase the opening of the valves to full open.

- Now we can see that the boiling temperature starts increasing and the vacuum starts dropping.

- The vacuum drop to about 85% which is an indication that evaporation is started.

- Open the valve from fresh water pump to drain.

- Switch on the salinometer if it has to be started manually. Generally it is on auto start.

- Now start fresh water pump and taste the water coming out of the drain.

- When fresh water starts producing it is seen that the boiling temperature drops again slightly and vacuum comes back to the normal value.

- Check the water coming out of the salinometer is not salty and also check the reading of the salinometer. This is done to see if the salinometer is working properly or not and to prevent the whole fresh water from getting contaminated with salt water. The value of salinometer is kept below 10ppm.

- After checking the taste of the water coming out of the salinometer, open valve for tank from the pump and close drain valve.

Stopping the Fresh water Generator

- Close the jacket water inlet valves. Generally inlet is closed first and then the outlet valve.

- Close the valve for feed water treatment.

- Stop fresh water pump.

- Switch off the salinometer.

- Stop sea water pump (also known as ejector pump).

- Open vacuum valve.

- Close sea water suction valve and overboard valve. This is generally not required as they are non- return valves. However, in case of valve leaking or damage, these valves are to be closed without fail.

Watch this video for better understanding of how freshwater is generated:

You may also like to read – Concept: A Life Raft that Makes Drinking Water from Seawater

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

thank you for this great web side i feel confident and ever happy as a marine engineer because you feed us with latest news keep it and have a wonderful weekend cheers..

THANK YOU A LOT FOR SHARING YOUR KNOWLEDGE AND VIEWS ,IT REALLY HELPS TRAINEES LIKE ME. GOOD JOB. KEEP IT UP.

Thanks for sharing your knowledge… I’m happy

The above given information is very useful for me..but I need the vaccum range which is created inside the evaporator.. Please kindly mail me the answer..

vaccum range in the evaporator of FWF is 75mm of Hg.

vaccum gauge shows up to 76mm of Hg.

Thank you!

Very well said.

Many Thank…

thank you for the good knowledge you are giving out, am really happy whenever i come across your reports, it always up date me as a marine engineer, God bless you.

What is the rule of vacuum in fw generator?

The fresh water generator of the another one way is batch distillation. this is expansive. vacuum is created for oil vacuum pump or water vacuum pump. the full vacuum is 760 mmHg

Please send me more of marine egineering stuffs (how they work)

We need people like you in our marine practice field. Build ” CARE and SHARE “, in case if you have time .? Please share again for subject to ” PURIFIER ” with much appreciate in advance.

Thank you very much, it is very informative, easy to understand.. May God bless you

well done, keep it up

thankx for helping the peoples

Thanks for sharing this blog. The blog was very interesting & useful. Got to know more about it. Keep Blogging.

what happens to the salt that is produced during the process.

@Abey: Brine ejector removes the salt and discharge it overboard

What is vaccume valve and why water is feeding to the evaporator through orifice

@Ashutosh: Vacuum breaker valve is provided to break the vacuum while stopping the FWG.

An orifice is fitted to control the supply rate of water to the evaporator.

Why the steam generated will not get ejected with air to create vaccum.. Why only air get ejected..????

hello

thanks for share you knowledge.

I would like to know the reason for this sequence: “Always open the outlet valve first and then inlet valve” in the starting the system; and “Close the jacket water inlet valves. Generally inlet is closed first and then the outlet valve.”in the stopping. if it is a heat exchanger, shouldn’t I regulate the flow by the entry?

thanks once more

THANKS FOR SHARING

Glad you liked it!

Would you kindly reply, Why vaccum is not made 100% in Fresh water Generator? Why 90-93% preferred, why not 100%

Alaqua works in the department of manufacturing evaporators, crystallizers, and distillation systems. We design and manufacture them for the chemical, environmental, food, dairy, beverage, and pharmaceutical industries.