Download 18 FREE Maritime eBooks

7 Technologies To Reduce Fuel Consumption Of Ships

Reducing fuel consumption and carbon emissions are two of the main concerns of the shipping industry today. A lot has already been done in terms of research and development to make the ultimate green ship. From renewable/ alternate sources of energy to design modifications, the industry has constantly improved its technology for an enhanced form of sustainable shipping.

LNG fuel, dual-fuel engines and design modifications are being extensively explored to reduce operating costs and to find eco-friendly ways to meet stringent environmental regulations.

In this article, we will take a look at both – some of the most commonly used methods and some of the latest technologies introduced in the industry recently.

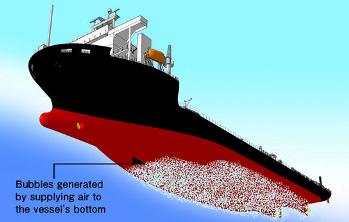

1. Air Lubrication

Air Lubrication System is a method to reduce the resistance between the ship’s hull and seawater using air bubbles. Also known as the “Bubble technology”, it works on the principle of supplying air to the ship’s underside in order to create a layer of tiny bubbles that would help in reducing the friction between the hull and the seawater.

The air bubble distribution across the hull surface reduces the resistance working on the ship’s hull, creating energy-saving effects. With the right ship hull design, the air lubrication system is expected to achieve up to 10-15% reduction of CO2 emissions, along with significant savings of fuel.

Silverstream Technologies has installed their air lubrication system- Silverstream System on the vessel of Norwegian Cruise Line. It is the first commercial installation for improving operational and environmental efficiencies as a means of reducing emissions, fuel costs, and improving the sustainability of their operations. The Silverstream System produces a thin layer of microbubbles that creates a single ‘air carpet’ along the hull of the vessel. This reduces the frictional resistance between the water and hull and improves the vessel’s operational efficiency, reducing fuel consumption and associated emissions. The technology can be added to new build design or retrofitted to an existing ship within just 14 days.

2. Fuel Saving Propeller Attachment

Hyundai Heavy Industries (HHI) has used an energy-saving device called Hi-FIN attached at the hub of the ship propeller, which generates countering swirls that offset the swirls generated by the propeller, and thus improves propulsion efficiency.

According to a year-long trial of the energy-saving device installed on a 162,000 m3 LNG carrier, HHI found that Hi-FIN can save up to 2.5 % of fuel in comparison with the same type of vessels without Hi-FIN. If the fuel-saving ratio is calculated on the basis of an 8,600 TEU containership, the owners or operators of the containership can save about $750,000 per year or $19 million for 25 years, an estimated lifetime of the ship.

HHI has won orders of Hi-FIN for over 30 ships to date, and the company expects more orders now that it can install the device on broader types of ships from LNG carriers to almost all types of ships including VLCC, LPG carriers and containerships.

3. Onboard DC Grid System

Onboard DC Grid system introduced by ABB helps vessels reduce their fuel consumption, cut noise and trim their environmental impact. The system which allows engines to run at variable speeds for top fuel efficiency at each load level has been identified to reduce specific fuel oil consumption of up to 27 per cent, according to the measurements and tests, conducted by Pon Power in collaboration with ABB on Myklebusthaug Offshore’s platform supply vessel Dina Star.

In addition to reducing fuel consumption, the tests also showed 30 per cent engine room noise reduction, contributing to improved working conditions aboard the vessel.

4. Low Loss Hybrid Energy System

The Low Loss Hybrid (LLH) System by Wartsila is an innovative technology which utilises different power sources in combination with energy storage devices to operate the prime movers closest to their optimum performance. A key feature of the system is its ability to reduce transient engine loads that cause increased fuel consumption and added emissions. The Wartsila LLH system is integrated with the inverter control units and interfaces with the conventional power management system.

Furthermore, by increasing the power redundancy, the system allows the engine to operate closer to its optimum design point where it has the highest efficiency and least emissions. Reduced maintenance and increased system performance through rapid response from the energy storage system are also among the benefits offered. The overall hybrid control system is the key element in the total control and stability of the ship’s electrical system and the energy flows.

In addition to annual fuel savings of up to 15 per cent, depending on the type and configuration of the engine and mission profile, the LLH ensures a substantial reduction in exhaust gas emissions.

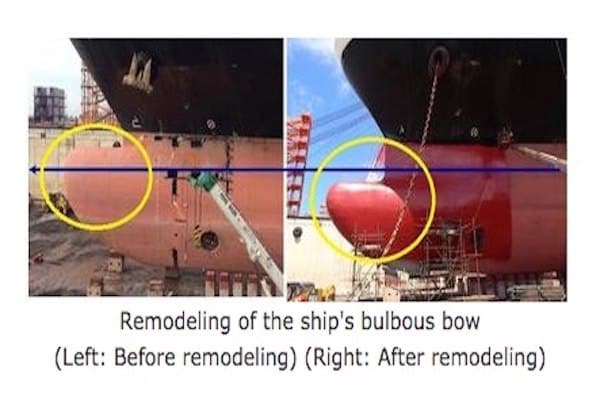

5. Nose Job – Modifying Ship’s Bulbous Bow

Modifying the ship’s bulbous bow is an efficient way to reduce fuel consumption of ships. Companies like NYK group and Maersk line has used this technique successfully to improve fuel consumption.

NYK group has made bulbous bow energy-saving adjustments to a containership resulting in a verified 23 per cent reduction in carbon dioxide (CO2) emissions over half a year, whereas Maersk group was able to reduce fuel costs by approximately 8 per cent in the current slow-steaming environment. The Clipper group was also able to get significant fuel savings with the same method.

DNV also carried out a comprehensive study to develop a new bulbous bow shape optimised for the expected trading conditions. After the planned “nose job” in drydock, onboard measurements showed reduced fuel consumption by almost 1,000 tonnes per year.

6. Fuel Oil Emulsion (FOE) technology

Fuel Oil Emulsion (FOE) technology by Blended Fuel Solutions burns more completely than unmodified fuel and so uses less fuel, emissions are lower and the engines run cooler and so should require less maintenance. This would reduce the use of fuel and the level of emissions as well as give a significant financial saving.

A trial conducted of the technology showed reduced fuel consumption and emissions.

7. Wind and Solar Power

Wind energy is seen as one of the most promising sources of alternative energies for sea-going vessels. A variety of methods/technologies have been explored to harness the power of wind energy.

Sea trials of a new wind propulsion technology by Norsepower confirmed fuel savings of 2.6% using a single small Rotor Sail.

Also, a new design of ro-pax vessel launched by Deltamarin features six-rotor sails to reduce fuel consumption.

Another technology named Auxiliary Sail Propulsion System (ASPS) by Windship Technology Ltd uses fixed wing sail technology. In this system two 35 metre high masts installed on the deck of a vessel will each have three aerodynamic wings fitted.

The masts or rigs rotate automatically to exploit the power of the prevailing wind and, as the speeds and angles of the wind change, the system develops more power allowing reductions in engine power to be made in order to achieve the same speed and so maximise on fuel saving.

Just like wind energy, solar power is also being extensively explored as an alternate source of energy on board ships. Eco marine power has successful completed the trial of its solar power solutions, which will now be released for commercial use.

Apart from the above mentioned technologies and methods, a lot of research is also being made in the field of anti-fouling paints, software tools and low fuel consumption marine engines. It is hoped that with the pace at which technology is advancing in the industry, solutions favourable in terms of environmental regulations and energy efficiency are expected to arrive sooner than expected.

Note: Please do note that this is not an exhaustive list but a compilation of most common and recent practices in the industry.

Over to you..

Do you know any other commonly used fuel-saving method used on ships today?

Let’s know in the comments below.

Disclaimer :

The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

Disclaimer :

The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

Related Articles

⚓️ Enhance Your Knowledge. Prevent Accidents. Stay Safe at Sea.

1. eBooks for Engine Department

Master machinery operations, troubleshooting, and safety procedures with expertly written guides tailored for marine engineers. Prevent costly breakdowns and onboard accidents through practical knowledge.

👉 Explore Engine Department eBooks

2. eBooks for Deck Department

Sharpen your seamanship, navigation, and cargo-handling skills with real-world case studies and practical insights designed for deck officers and cadets.

👉Discover Deck Department eBooks

3. eBooks on Electrical Fundamentals & Issues

Understand marine electrical systems, identify potential faults, and prevent onboard electrical failures with step-by-step explanations from industry experts.

4. Pocket Guides for Quick Reference

Compact, handy, and loaded with essential checklists—perfect for on-the-go reference during operations and emergencies at sea.

5. Combo Packs to Save Big

Access multiple expert eBooks at discounted prices. Ideal for professionals seeking complete safety and operational knowledge across various ship departments.

6. Digital Maritime Courses – Learn at Your Own Pace

Upgrade your competence with Marine Insight Academy’s online courses. Learn from industry professionals anytime, anywhere, and become a safer, smarter seafarer.

Subscribe To Our Daily Newsletter

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

ZSHIPS International ccc ltd a new Canadian startup company is developing a 100% renewable energy ship propulsion system. Zero emissions, Zero fossil fuel, Zero fuel costs.

For more information contact [email protected]

https://www.vaf.nl/products/overview/shaft-power-thrust-meter/

1- Amazingly, I very often see, seeming to me, but I’m not a specialist, poorly designed bow bulbs, typically not under the real flotation line, on giant ships such as cruising ships, ships in which the load, mainly passengers, make very little change on flotation depth, very differently it me be on giant container bearer ships or others big cargo boats.

2- I imagine that this device works well (annulation of two diphasic waves train) for a certain speed. Why not have possibility of changing a little its shape or its length at different speed?.

Correct trim will save fuel. Also, sometimes, more ballast water in the ship will save fuel. More ballast will in some conditions position the ‘nose’ more correct in the waterline and by this save fuel.

One way of maximizing the energy efficiency of the fuel oil is by recovering energy from waste gases. In a Waste Heat Recovery System (WHRS), the vast amounts of energy stored in exhaust gases from ships and power plants are extracted and put to use instead of going to waste.

Fuel reductions of between 4-11 % are possible, depending on the selected WHRS solution. The larger the engine power, the greater the possible fuel savings. In addition to large fuel savings, a WHRS gives large CO2, NOx, SOx and particulate reduction to the benefit of the environment. Also, the payback time is short.

Bound4blue will be going to sea trials pretty soon. These are rigid sails designed to be, additionally to autonomous, foldable.

@Jeppe: Thank you for your input

I have invented a marine propulsion that Utilizes ZFP energy of Quantum Vacuum available in every point of the marine environment. It can be scaled to any power. That is free energy. A ship with this propulsion would have been most economical as does not consumes fuel at all and has no emissions.

Datum Marine Shaft POwer Meter System:

https://datum-electronics.co.uk/product/commercial-marine-shaft-power-meter/

Hi Mariners Good morning! We are also a Startup company- SHALLOW WATERWAY SHIPPING PVT LTD – INDIA. We insist to use Double edge sword. We have solutions for Saving Fuel and thus reducing carbon emission into atmosphere by Focusing in enhancing Cargo Carrying capacity of each Boat or Ship and Boosting up the Utilisation of each Boat or Ship i.e. Backhaul of cargo or Return voyage cargo so in this way you are avoiding your Ballast Water Treatment issues as well. In short we should focus on increasing cargo carrying capacity per voyage rather than only Speed/Resistance in water of Ship or Boat. For more Consultancy and Advisory services in Port & Shipping/IWT/Coastal Shipping Cont.

By using the power of waves big fuel savings would be possible. A reservoir layer could be added to the sides of ships with one way openings in it. Waves force water through the openings so that the reservoirs contain high pressure water. If the water is released behind the ship it will propel the ship forward. The rougher the sea the greater the pressure and the greater the thrust and fuel saving.