What is Parametric Rolling in Container Ships?

Rolling and pitching is a part of every ship that is going out at the sea. The first thing you might think upon hearing the word “Parametric rolling” is that it must be a type of rolling movement occurring in ships.

Rolling and Pitching is a normal movement phenomenon that occurs in all kinds of ships, so what is new about this?

The difference is that “Parametric Rolling” is a type of movement that is experienced only on Container Ships.

Causes of Parametric Rolling

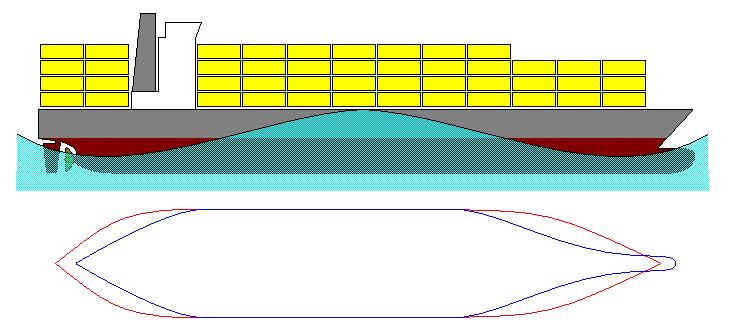

The size of container ships is increasing drastically as companies are looking forward to monster ships; for e.g. Maersk’s Triple-E Vessels. The new container ships coming to the market have a large bow flare and wide beams to decrease the frictional resistance which is generated when the ship fore-end passes through the water, making it streamlined with the hull.

As the wave crest travels along the hull, it results in flare immersion in the wave crest and the bow comes down. The stability (GM ) varies as a result of the pitching and rolling of the ship. The combination of buoyancy and wave excitation forces push the ship to the other side.

A similar action takes place as the bow goes down in the next wave cycle resulting in synchronous motion which leads to heavy rolling up to 30 degrees in a few cycles. This type of rolling is known as Parametric rolling.

This phenomenon occurs only when the sea condition is in the head/stern or anywhere near to them. There are two pitch cycles- maximum and minimum.

The period of the roll is half the natural rolling period which coincides with a large phase angle and maximum roll always occurs when the ship is pitching down i.e. bow is down.

Effects of Parametric Roll

- Heavy stresses in ship structure especially in fore and aft parts

- Extreme stresses on the container and their securing system resulting in failure of the same and even loss of containers

- Unpleasant for the crew of the ship

- Variation in a load of ship’s propulsion engine

- If not tackled quickly, it can result in capsizing of ship

What to do in case of Parametric Rolling on ships?

- Do not panic in such a situation. Keep your calm

- If rolling and pitching occur simultaneously, avoid a head-on sea and change the route.

- Always maintain a correct GM. The ship should not be too tender or too stiff.

- The roll damping measures must be quickly used

Do you have info to share with us ? Suggest a correction

Latest Ship Safety Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Why it takes place only in containers ..?

Due to the shape of the hull of a container ship (narrow relative to length) the bouancy shifts due to the change of the under water volume when the waves are coming from the quarter causing avirtual decrease of gm, if the gm is not suffiecient and if you didnt take asafety margin this can lead to this problem, the solution is simple, change of course/speed, fill up the DB tanks to increase gm. This will not happen to abulk carrier because its hull is almost identical along its length (like box shape) and the gm is always high and not an issue at all in this case (especially when the vessel is in ballast condition, gm can be 7-8 meters).

Hello I’m Michele Tomassoni, owner of the company that sells roll containers in Italy, Mi.To. SM Group. Congratulations for the article, very well written.

Full of salient points. Don’t stop beniveilg or writing!

PR does occur in other types of ships with similar hull properties. Some LCTCs have for example experienced PR.

If you look at the container hull shape, one can notice that it is less bulky than a tanker or bulk carrier ships of equivalent dimensions. Prismatic coefficient or block coefficient will have smaller values. If one look at the midship, it is easy to roll both directions. That means roll damping is less. So the whole shape which is more streamlined is also responsible for such a type roll motion.

what is the required speed of main engine during the rolling pitching ect.

is it slow speed?

@ Ambra: It will depend on several factors such as – Load on the ship, cargo onboard the ship, sea and wind state, degree of rolling etc.

Correctly and breifed well thanks

Glad you liked it @Darrel