Single Phasing in Electrical Motors: Causes, Effects, and Protection Methods

For proper working of any 3 phase induction motor, it must be connected to a 3 phase alternating current (ac) power supply of rated voltage and load. Once these three-phase motors are started, they will continue to run even if one of the three-phase supply lines gets disconnected. The loss of current through one of these phase supplies is described as single phasing.

The ship is fitted with hundreds of motor,s which are responsible for running different pumps, machinery, and systems. The critical machinery such as steering gear, main engine, generator, boiler etc. have 3 phase motors attached to them which run one or the other main or auxiliary system for them.

Related Reading: Electric Propulsion System For Ships

A 3 phase motor of 440V is, in general, the standard frame, squirrel cage induction type designed for AC 440v 3 phase of 60 Hz. Only small capacity motors of 0.4 KW or less, mainly used for lighting and other low power systems, are single phase motor of 220V 60 Hz operation.

Related Reading: Understanding The Importance Of Marine Navigation Lighting

Causes of Single Phasing

Single phasing is a power supply-related electrical fault in case of an induction motor. It occurs when one of the 3 phase circuits in a three-phase motor is opened; hence the remaining circuits carry excess current. This condition of Single Phasing is usually caused when:-

– One or more out of the three back up fuse blows (or fuse wire melts if the fuse is of wire type)

– The motor circuit has contactors which supply the current. One of the contactors is open circuited.

– A wrong or improper setting of any of the protection devices provided on the motor can also lead to single phasing

– If contactor routines are not performed regularly, they might get covered or get coated with oxidation layer leading to single phasing.

– The relay contacts for the motor is damaged or broken

– One of the wire for the motor circuit is broken

– Due to equipment failure of the supply system

– Due to the short circuit in one phase of the star-connected or delta-connected motor

Related Reading: Motor Starting Panels On Ships: Maintenance and Routines

– Feeder or transformer fuse blow-up

Effect of Single Phasing

As mentioned earlier, a three-phase motor is an AC motor which is built to operate on a three-phase power source. The construction of both types of a motor is similar as they both have a stator and rotator. The single phase motor does not have a rotating field, but one that reverses 180 degrees. Usually, single phase motors are not self-starting. For that, they use additional provisions like switching out the start winding or a capacitor.

Single phasing problem on a 3 phase induction motor will have the following effects:

– If the motor is in a stopped condition, it cannot be started as a single phase motor cannot be a self-starter (as explained above) and also due to the safety system provided in 3 phase motor to protect it from overheating

– If the single phasing faults occur while the motor is operating, it will continue to run (unless provided by additional safety cut-out system) because of the torque produced by the remaining two phases which is produced as per the demand by the load

– As the remaining two phase are doing additional work of the one default phase, they will be overheated which might result in critical damage to the windings

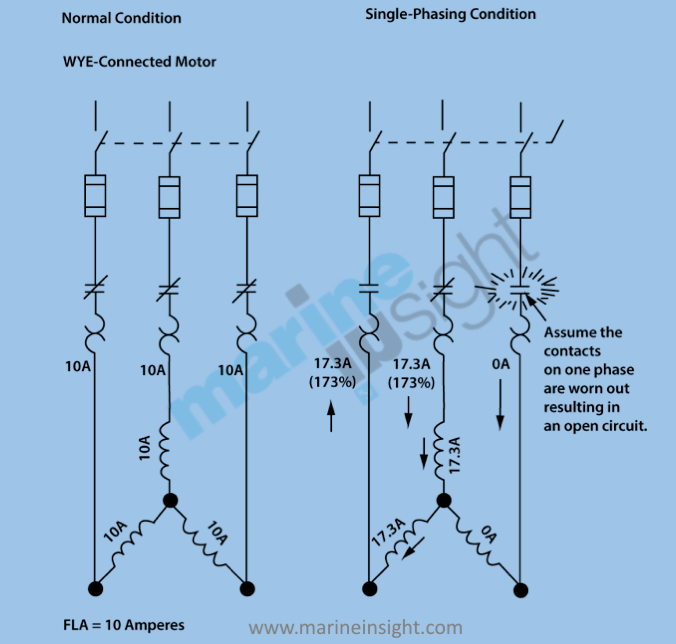

– The single phasing will lead to increase in the current flow by 2.4 times the average current value in the remaining two phases

Related Reading: 10 Ways to Achieve Energy Efficiency In Ship’s Electrical System

– Single Phasing reduces the speed of the motor, and its rpm will fluctuate

– The noise and vibration from the motor will be abnormal. This is the result of uneven torque produced by the remaining two phases

– Almost all the motor system in the ship has a standby arrangement. If the motor is selected for standby, with single phasing problem – It will not start leading to failure of the related system

– If the problem is not addressed and motor operation is continued, windings will melt due to overheating and can lead to short-circuiting or earthing

Related Reading: How to find earth fault on board ships?

– In such condition, if the crew of a ship comes in contact with the motor, he will get an electrical shock which can even be fatal. Overheating of winding is primarily due to the flow of negative sequence current.

– It may cause overloading of the power generation machine, i.e. auxiliary engine, and its alternator

How to Protect Motor from Damage Due to Single Phasing?

Such a condition requires that the motor is provided with protection that will disconnect it from the system before the motor is permanently damaged.

All motors above 500 KW are to be provided with protection devices or equipment to prevent any damage due to single phasing.

The rule stated above does not apply to motors of the steering gear system installed on the ship. Only on the detection of the single phasing, an alarm will be sounded; however, the motor will not stop as the continued operation of the steering motor is essential for safety or propulsion of the ship, especially when the vessel is in congested waters or under manoeuvring.

Related Reading: 8 Common Problems Found In Steering Gear System Of Ships

The most commonly used protection devices for single phasing are:-

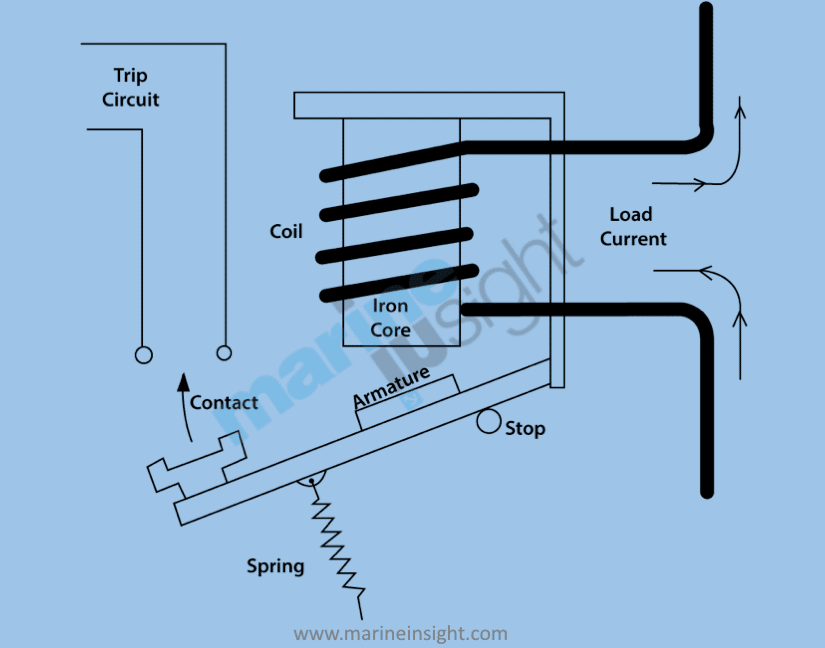

1) Electromagnetic Overload Device

In this device, all the three phases of the motor are fitted with an overload relay. If there is an increase in the value of the current, then this relay activates automatically and the motor trips.

This device works on the principle of the electromagnetic effect produced due to the current.

As the current value increases, the electromagnet in the coil also increases which pulls the relay and activates the trip relay, and the motor is stopped.

Related Reading: Maintenance Of Electrical Relay On Ship’s Electrical Circuit

The time delay is provided in this system because while starting the motor draws a lot of currents which can trip the motor.

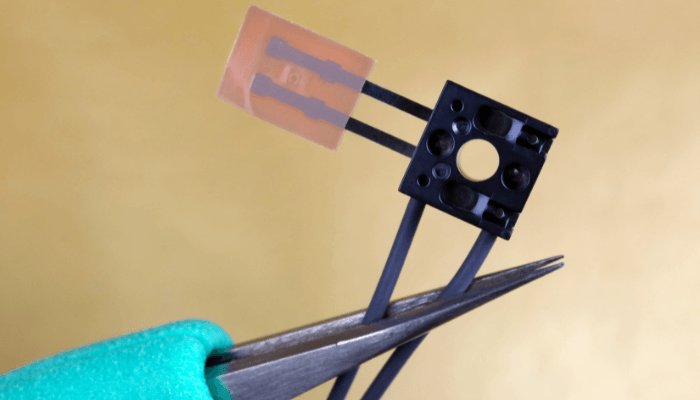

2) Thermistors

Credit: Wikimedia

Thermistors are small thermal devices which are used together with an electromagnetic overload relay. The thermistors are inserted in the three windings of the motor. Any increase in the current will cause heating in the windings, which is detected by the thermistors that send signals to the amplifier.

Related Reading: Amplifier Circuit Or Operational Amplifier Used On Ship

The amplifier is connected to the electromagnetic relay. As soon as a signal is received from thermistor about overheating, this amplifier increases the current value in the coil of an electromagnetic relay which activates the trip and the motor stops or trips.

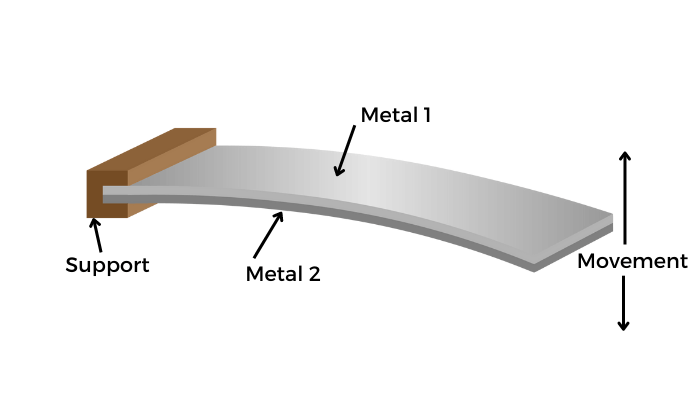

3) Bi-metal strip

In this method, the bimetallic strip is placed in such a way that it detects the overheating in the circuit. As soon as overheating is detected, this bimetallic strip tries to expand due to two different metal used and because they have a different coefficient of expansion. The strip attempts to bend towards the metal having a high coefficient of expansion and finally completes the trip circuit and the motor trips.

4) Standard motor starter overload protection

It is provided in 3 phase motor to takes care of the single phasing condition. Overload heaters are provided in all the phases which detect any overload in the phase, and if the load goes far above spec for the motor, the heaters trip the starter off before the motor winding is damaged.

How to detect the single phasing fault?

It is vital for the ship’s crew to know if the motor has gone single phasing. A 3 phase induction motor is usually provided with overload detection device for single phasing detection. Still, a machine can go wrong at any time, and as an experienced ship engineer, she/he must know how the motor usually sounds, feel or operate.

Related Reading: 10 Electrical Jobs Marine Engineers Must Know Onboard Ships

It is important to keep all the sense alert when performing checks on ships motor to detect these problems which are related to single phasing:

– Unusual Humming noise coming from the motor

– The motor is vibrating at a higher frequency than usual

– The smell of hot and burnt copper (insulation) ( Find out how insulation testing using megger meter helps to prevent any accident)

– Visible light smoke/fumes from the motor casing

To troubleshoot and again run the motor from single phase to three phase, stop the motor immediately and switch to the standby motor. Check the parameters of the motor as stated in the plate attached to the casing and troubleshoot the motor.

Do a proper visual Inspections of the motor winding and check the earth Continuity and Resistance Test. A Power Supply Test to the motor is also performed to locate the problem if the fault is not diagnosed by the motor.

Related Reading: How To Overhaul Motors On Ships

Once the problem is located and rectified, box up the motor. Before connecting the motor to the load, switch on the controls for the motor and test run the motor for all the important parameters (e.g. voltage, current, rpm, temperature etc.) and compare with the values stamped in the plate.

Ensure all the measurements are within the nameplate specifications. Once the idle test run of the motor is satisfied, engage the load and monitor the motor performance to ensure the problem is rectified and the motor is now operating efficiently in 3 phases.

You may also like to read – What is Marine Electricity And How It is Generated?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

The question is:

Should an ETO to do the cleaning alternators/shaft gen.sets/bow or stern thrusters and such might and important motors during the scheduled drydocking maintenance of the vessel.

In my opinion such job should be organized by ship’s company and must be done by shore electrical department to clean up, heat and varnish’em in proper manner cause that is too important for future for motors (more then 600kW motors).

I did not mean an emergency case. Is it responsibility of an ETO?

Your opinions bros?

Thanks

@ Alex: Yes They are very Important machinery but company want to save costs.If a trained professional is available onboard, why to spend dollars on shore service. Your point is valid only for big shipping companies as all small organisation wants to run their ship at minimal operating cost.

With ETO becoming such an important job position, now IMO has also decided to have a COC for such position whihc will defiantly improve the overall technical skills of a person.

How to avoid single phasing?

help pls. i am a new eto can anyone help me on how to synchronize a sperry marine gyro repeater.. thanks in anvance

Am new to this cause can anyone help me to this cause marine electrician in terms of books, Thanks in advance from Benjamin Darko in Ghana.

pls am 56yrs old n I want to b a qualified E T O can anyone. help me

i have 3phase induction motor . T taking in balace current . 12,12,5 A

Can u have one article regarding all the pipe line in engine room in much simplified view with description,it will be very much helpful

Waiting for the article

I’m taking a wastewater test online and it ask A particular electric motor is wound for 3-phase current. If one phase cuts out while it is in operation, the motor will

A. Continue to run without danger and will do a normal amount of work.

B. Continue to run without danger but the work done will be reduced one-third.

C.. Overheat and will be damaged unless it is stopped by a thermal control device.

D. Stop immediately.

now I thought it was c but the answer sheet says d can someone please explain everywhere I’ve seen implies that c is the correct answer

The most correct answer is D . The conditions of C will occur over time if the supply power is not cut to the motor. C is also correct but it is not the MOST correct answer.

The answer is C NOT D! The motor if correctly protected will trip on differential OCR thermally.

Paul

The answer is C the motor will continue to run but would overheat over period of time . Now D is if the motor was using overload protection it would definitely stop before the motor damage.

The protective devices are there for the motor protection and eventually, in most of the cases, will protect the motor. But if the fault is manually detected, the motor should be stopped immediately to contain the damage to it and the supply euipment, without waiting for the automatic protection

@Ajay: Thank you for your valuable input.

Fuse in the line is not effective to the protection against single phasing

in the case of induction motor having stator as:

A. Star

C. Delta connected

B. Zig zag connected

D. None of above

What does single phasing on a motor mean ?

A Optimal operation

B In-phase system

C Loss of 1 power phase

D One-stege operation

The following blog is really informational and comprehending.I want to add on that I have been facing a very concurrent issue of the Frozen evaporator coils.I have followed out the basic troubleshooting. Suggest us what to add on

Thanks to you guys for all the interesting and educating write up.