Ohmmeter – Construction and Operation Explained

The most important factor for the staff working onboard ships (or in any other industry) is – the personal safety and the safety features incorporated in machinery and systems.

Electrical components and mechanical systems present in the engine room are mainly maintained by the electrical officer.

The routine maintenance for electrical machinery involves checking of insulation resistance, which is done by an instrument called “ohmmeter”.

The insulation resistance test is done to ensure the integrity, i.e. to resist the current flow outside the equipment, and keeping it within the dedicated parts.

The measured “IR” (Insulation resistance) can be of a wire, cable or motor/generator windings. In simple terms, every electrical insulation should have the opposite characteristic as the conductor.

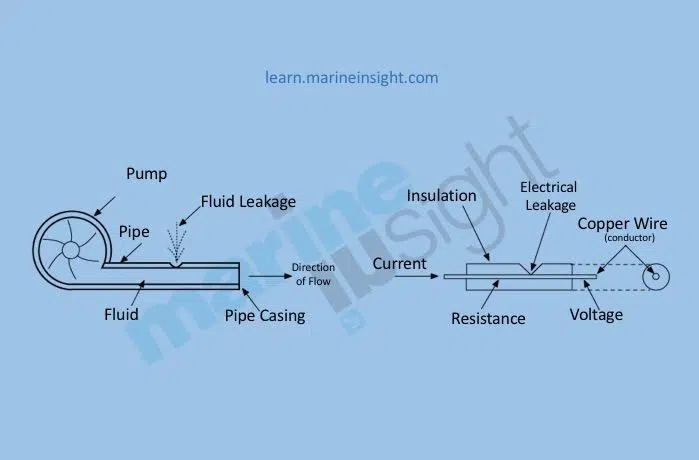

For e.g., in the pump casing and pipes in a water carrying system acts as the insulation, which prevents the leakage of water. Similarly, in an electrical wiring system, the wire insulation prevents the leakage of current which is carried in a copper wire.

Insulation Resistance – Importance And Causes of Decrease

Insulation resistance (I.R) is a critical parameter as it’s directly related to personal safety, the safety of machinery and power reliability.

The I.R value of electric devise changes with ageing, mechanical and electrical stresses, temperature, contamination, atmosphere, humidity etc.

It is therefore important for the engineers and electrical officers to identify this detection to avoid any accidents on board ships because of electric shock.

Another common cause of the decrease in the value of insulation resistance is the ingress of water. If the electrical equipment is wet due to freshwater, it can directly be dried out for checking the IR values.

However, in the case of seawater ingress, the first step is to wash it with fresh water to remove the salt deposits which will cause corrosion of metal parts and insulating surface.

Remove oil and grease from such equipment using a suitable solvent.

Any wet equipment on the ship is susceptible to voltage breakdown. Therefore, when using ohmmeter at the drying out stage, low voltage ohmmeter insulation tester (100 or 250 VDC) to be used.

If low voltage ohmmeter is not available, using slow cranking in a mechanical type 500 V ohmmeter can be done to achieve the results.

Sometimes, electrical ohmmeter is also provided with a test range in kilohms (kW). This test range measurement is the ideal initial check to be made on flooded equipment.

Why is Ohmmeter Testing Done?

As mentioned earlier, the insulation resistance of an electrical system degrades over time because of several factors. The insulation resistance needs to be tested to check the insulation quality (punctures in insulation) of the electrical system and to avoid any major or minor electrical shocks to operators.

Thus ohmmeter testing is carried out to find out information on leaking current and the areas where insulation has deteriorated because of excessive moisture and dirt in the electrical circuits.

Any specific circuit found faulty is then isolated and replaced/repaired to avoid any further problems and ensure the safety of the crew.

Use of Ohmmeter on a Ship (And in other industries)

The Ohmmeter is widely and frequently used by the ship’s officer for the following jobs:

- Testing an Earth/Ground connection

- Battery Testing

- Relay Testing

- Watthour Meter Testing

- Oil Testing

- Transformer Testing

- Circuit Breaker Testing

- Cable Fault Testing

- Power Quality Analysis

- Power Factor Testing

- Low Resistance Testing

- Motor winding testing

- Alternator winding testing

There is no fire hazard related to Ohmmeter insulation tester when used in a normal atmosphere. However, when using the instrument for testing equipment located in inflammable or hazardous atmospheres, it may lead to an explosion due to the spark created, when using the instrument.

Do not use the ohmmeter test equipment in an explosive atmosphere (such as the deck of an oil tanker ship).

Types Of Ohmmeter

Ohmmeter is a portable instrument which is used to measure the insulation resistance of the electrical machinery or system. It can be battery operated or mechanically operated (hand crank dc generator) and gives a direct reading in ohms. For this reason, it is also called as ohm meter.

Onboard ship, different systems are present with large voltage ratings and therefore ohmmeter comes in the range of 50, 500, 1000, 2500, and 5000 V, thereby making ohmmeter meter suitable for applications on normal voltage equipment to more demanding high-voltage applications.

The categories of an ohmmeter test equipment can be divided into two:

- Electronic Type (Battery Operated)

- Manual Type (Hand Operated)

There are other types of ohmmeter available in the market, which is operated by an attached motor requiring an external power source for rotation.

This motor then rotates the generator fitted in the ohmmeter. As the overall size of such meter increases due to the addition of a motor, and their dependency on a power source, they are not much preferred for use on ships.

Electronic Type Ohmmeter:

The electronic type ohmmeter, also known as electrical ohmmeter, is compact of all types and uses a battery for operation. The important parts of this ohmmeter test equipment are:

Digital Display:- To show the insulation resistance value in digital form

Testing Wires:- Two-wire leads for connecting ohmmeter with an electrical external system for testing the later.

Selection Switches:- Different parameter ranges are provided on the meter, which can be selected by using the selection switches.

Indicators:- Different indicators are incorporated into the instrument to give a visual and audible indication when the instrument is ON, for a warning, parameter status etc.

The construction and parts of electrical ohmmeter will vary depending upon the manufacturer, however, the basic construction and operation remain the same.

Advantages Of Electronic Ohmmeter

- Has a very high measurement accuracy

- Easy to operate for one person

- The digital display makes it easy to read the IR value

- Robust and safe to use

- Less maintenance as compare to other types

- Works well in congested spaces

- Handy and compact to carry

- Less time-consuming operation

Disadvantages of Electronic Ohmmeter

- Requires an external source of energy to energize i.e. Dry cell

- High initial cost

Handheld Type Ohmmeter:

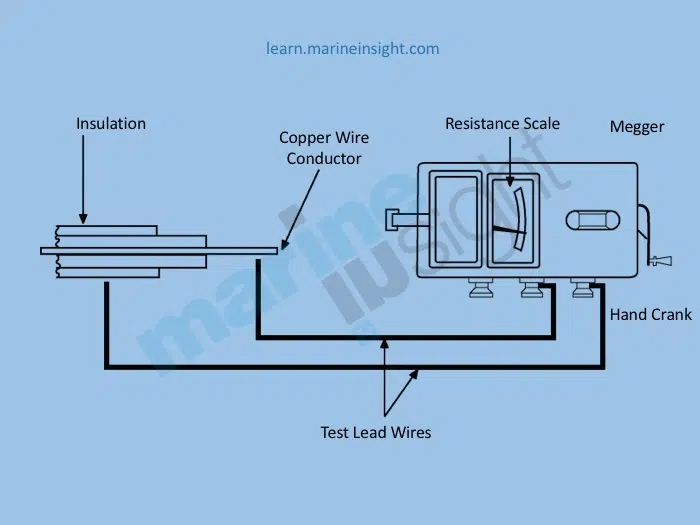

The handheld type ohmmeter is still used on the ship as it provides service without the need for battery and external power source. The main parts of such ohmmeter testing unit comprise of:

Display:- An Analog display is provided, which is a pointer and a scale, to show the IR value recording.

Hand Crank: As this a manually operated ohmmeter, a hand crank is provided which can be rotated to generate the required voltage, which runs through the electrical system for an insulation resistance test.

Wire Leads:- Two-wire leads are provided which can be connected to the electrical system which needs to be checked.

Advantages of Hand Operated Ohmmeter

- No external source required to operate

- An excellent choice for emergency use

- Cheaper than the electrical ohmmeter

Disadvantages of Hand Operated Ohmmeter

- At least 2 ship staff are required for operating handheld ohmmeter. one for rotating the crank and other to connect wire leads to test the IR of the equipment

- Not highly accurate as electronic ohmmeter as the value will vary with the rotation of the crank.

- It needs a stable place to operate and record the IR value, which is a little difficult to find at work sites.

- Unstable placement of tester may impact the result of IR value.

- Provides an analogue display result.

- Require very high care and safety during the use of the same.

- Time-consuming operation

Principle Of Ohmmeter Operation

The ohmmeter works on the principle of the moving coil instrument, which states then when a conductor carrying current is placed in a magnetic field, a force is exerted on the conductor.

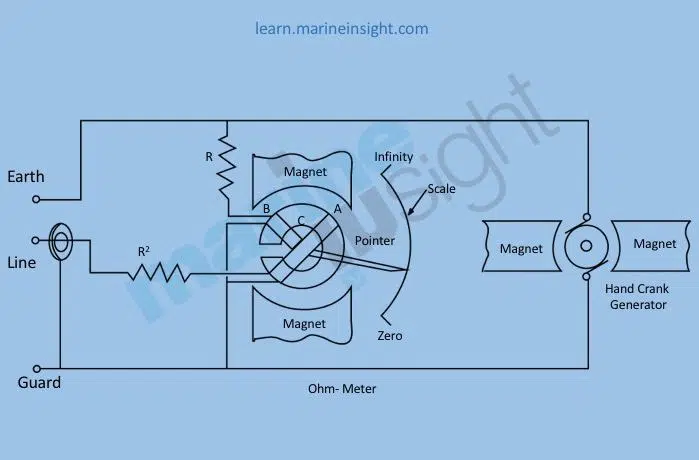

As seen in the figure below, when the current-carrying conductor comes in the magnetic field of the permanent magnet, a defecting torque is produced, which moves the pointer in the scale.

Construction Of Ohmmeter

The important construction features of Ohmmeter consist of following parts:

- Control and Deflecting coil: They are normally mounted at a right angle to each other and connected parallel to the generator. The polarities are such that the torque produced by them is in the opposite direction

- Permanent Magnet: Permanent magnet with north and south poles to produce a magnetic effect for deflection of the pointer.

- Pointer and scale: A pointer is attached to the coils and end of the pointer float on a scale which is in the range from “zero” to “infinity”. The unit for this is “ohms”.

- D.C generator or battery connection: Testing voltage is supplied by hand-operated D.C generator for manual operated Ohmmeter and a battery and electronic voltage charger for automatic type Ohmmeter.

- Pressure coil and current coil: Provided for preventing damage to the instrument in case of low external source resistance.

Working Of Ohmmeter

The voltage for testing is supplied by a hand generator incorporated in the instrument or by battery or electronic voltage charger. It is usually 250V or 500V and is smaller in size.

- A test volt of 500V D.C is suitable for testing ship’s equipment operating at 440V A.C. Test voltage of 1000V to 5000V is used onboard for high voltage system onboard.

- The current-carrying coil (deflecting coil) is connected in series and carries the current taken by the circuit under test. The pressure coil (control coil) is connected across the circuit.

- Current limiting resistor – CCR and PCR are connected in series with pressure and current coil to prevent damage in case of low resistance in the external source.

- In hand generator, the armature is moving in the field of a permanent magnet or vice versa, to generate a test voltage by electromagnetic induction effect.

- With an increase of potential voltage across the external circuit, the deflection of the pointer increases; and with an increase of current, the deflection of pointer decrease so the resultant torque on the movement is directly proportional to the potential difference and inversely proportional to the resistance.

- When the external circuit is open, the torque due to voltage coil will be maximum and the pointer will read “infinity”. When there is short circuit the pointer will read “0”.

General Inspection of Ohmmeter

– Check for loose connections, defective insulation, and cleanliness

– Check meter stop and pointer for damage

– Check the carrying case for corrosion, foam fungus etc.

– Check for easy cranking arrangement for mechanical ohmmeter

– Check the foam rubber lining if fitted

– Check the battery level for digital ohmmeter

– Check all indicators are working fine

General Maintenance of Ohmmeter:

- Digital multimeter is provided with a fuse. Replace it if the ohmmeter is not working

- Clean the surface from dust, dirt, grease fungus etc.

- Remove dust or dirt from terminals with a soft brush

- Clean the display using a soft cloth

- Clean the cables, meter glass, and the exterior surface with a clean, soft cloth. Dampen the cloth with water if required

What Things to Record After an Ohmmeter Test?

When performing an ohmmeter test on machinery or equipment, the following things to be recorded:

- Name and location of the equipment/ wiring

- The date on which the test is performed

- The Insulation Resistance values of test results along with time

- Range, voltage, and serial number of the ohmmeter instrument used

- The temperature of the apparatus during the time of the IR test

- When doing IR test of bigger machines such as alternator, transformer etc. wet and dry bulb temperatures and dew-point determinations to be noted

- Insulation resistance measurement corrected for temperature

Always remember to disconnect the machinery and equipment being tested for insulation resistance as there is a possibility of voltages being induced in apparatus under test or lines to which it is connected (because of proximity to energized high voltage equipment).

Use required PPEs such as rubber gloves etc. when connecting the wire leads to test the apparatus for performing the insulation resistance test.

Some ohmmeter may be provided with a voltage scale to ensure the line to be tested does not have any voltage for insulation testing.

You might also like to read:

- 10 Electrical Jobs Marine Engineers Must Know On Board Ships

- 10 Ways to Achieve Energy Efficiency in Ship’s Electrical System

- Electrical Propulsion System in Ships

- Single Phasing in Electrical Motors: Causes, Effects, and Protection Methods

- How to Minimize the Risks of an Electrical Shock on a Ship?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

we check IR test with voltage as per ohm law current is there so who we handle current

But which voltage on reducing Ac are dc not output

very nice

What’s the minimum resistance that a certain equipment is considered grounded.

in what electrical degree connected to current coil and pressure coil in megger?

Hi, have you got a tutorial for megger OTS 100AF?

@Virgil: As of now, we do not have it.

Insulation Testers are a very powerful tool.

@mecoinst

These equipment are very suitable for use on ships, but in my country Iran is very expensive. I suggest that other brands be used alongside this brand to reduce overall costs.not bad see the following site for other equipment:

Megger is a combination of ?

@Vijay: Ohm meter and generator

What happened if we apply Meggar in live electrical circuit?