Latest Articles

What is Voyage Management System?

What is the Purpose of DG Shipping?

A Guide To Nautical Science Diploma

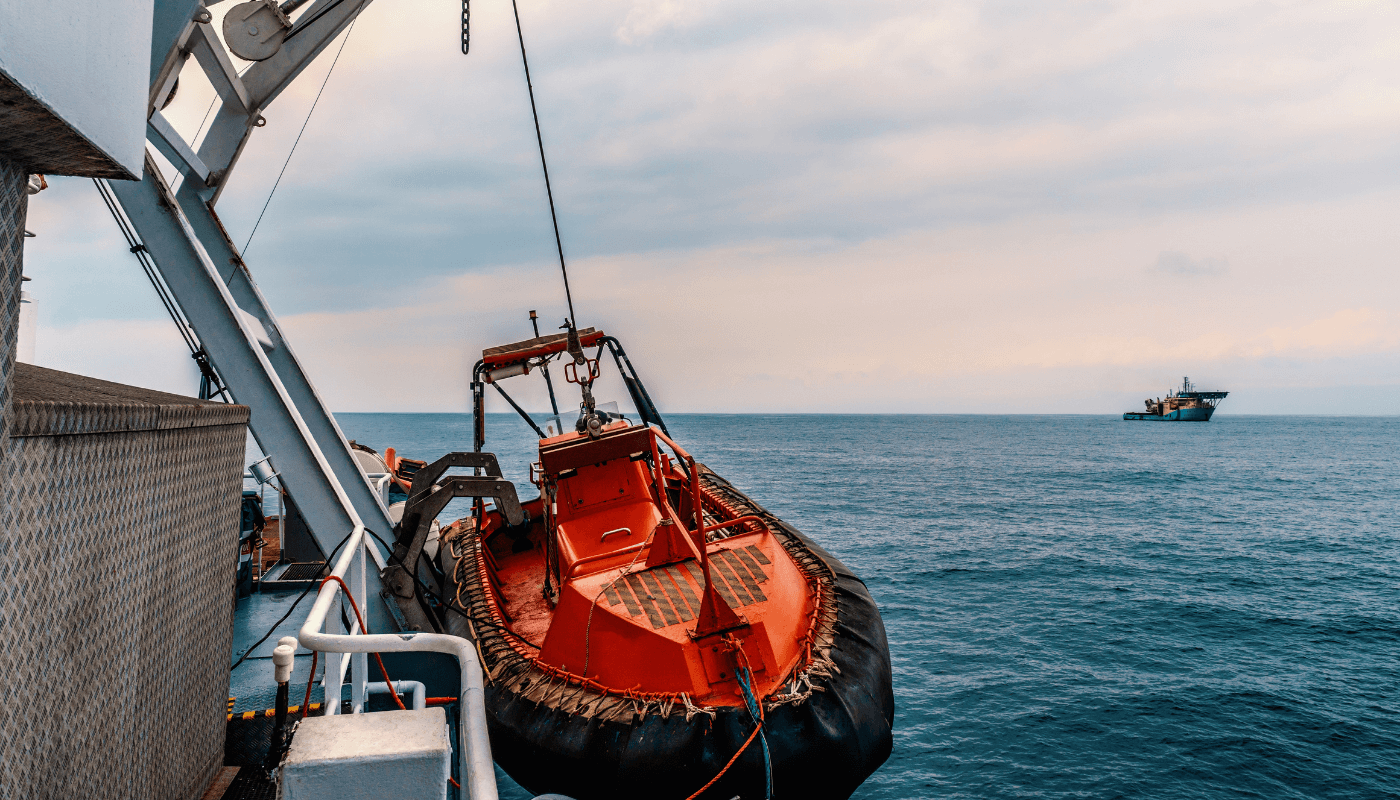

What are Fast Rescue Boats?

What are Logistics Risks?

A Guide To IMU CET Exam 2024

Maritime Law & Logistics

MARPOL (The International Convention for Prevention of Marine Pollution For Ships): The Ultimate Guide

The Ultimate Shipping Container Dimensions Guide

Read More From This Category >