What is Clearance Volume or Bumping Clearance in Air Compressors?

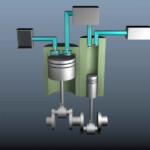

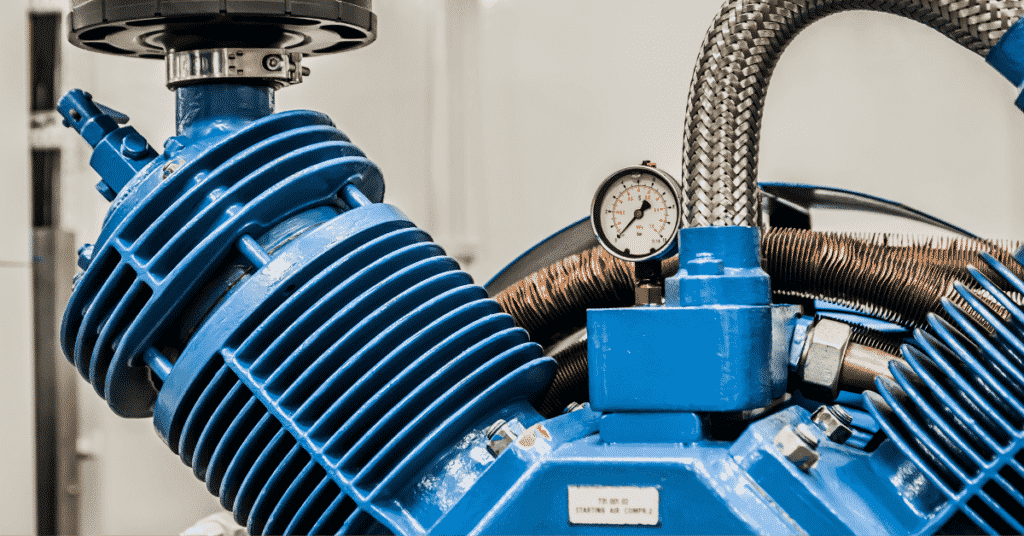

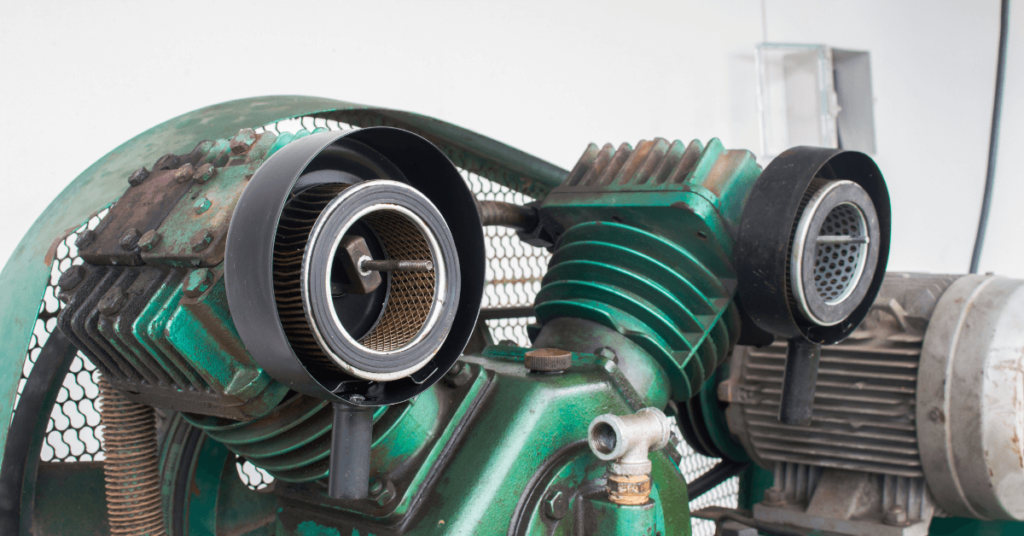

Clearance volume or bumping clearance is the space between the top of the piston and the cylinder head of an air compressor. This clearance is an important aspect of the compressors and should be as less as practically possible to improve the volumetric efficiency of the compressor. The clearance volume should not be too less or too more. Moreover, it affects the efficiency of the machinery and thus should be checked at regular intervals of time.

Significance and Effects of Bumping Clearance

In an air compressor, when the discharge valve closes in the end of the compression cycle, a small amount of high pressure air is trapped in the clearance volume.

Before again taking suction, the air trapped in the clearance volume must expand below the suction pressure i.e. below the atmospheric pressure.

The expansion of this trapped air in the clearance volume causes effective loss of stroke due to which the volumetric efficiency of compressor drops. Therefore, the clearance volume has a significant effect on the efficiency of the compressor.

Effects Due to Less Clearance

Small clearance volume may result in piston banging or colliding to the cylinder head.

This is dangerous when the compressor when is running in unloaded condition without any resistance to the movement of the piston.

Effects Due to Large Clearance

Large bumping clearance retards the formation of vacuum on the suction stroke and thus less air is drawn inside for compression and accordingly the weight of the air delivered is reduced proportional to the clearance volume.

Compressor has to run for a longer period to provide the necessary compression pressure.

Reasons for Change in Clearance Volume

During overhauls of the air compressor, if the gasket fitted between the cylinder head joints is of the wrong type, then the bumping clearance will increase, resulting in wear down of bottom bearings or wrong bearings are put in place.

How Bumping Clearance is checked?

Bumping clearance is checked by putting a lead ball or plastic gauges over the piston and then turning the compressor one revolution by hand.

By doing this the lead ball will compress and the thickness obtained is the clearance volume.

This thickness is measured with vernier caliper or micrometer and is then compared with the manufacturer’s value. Adjustments are made in case there is an offset in the value.

Adjustment of bumping clearance

Bumping clearance can be adjusted with the help of inserting shims (thin metallic plates) in the bottom bearings. Inserting shims will move the connecting rod and the piston which will change the clearance.

What should be the Bumping Clearance?

Generally bumping clearance depends on the manufacturer but as a thumb rule it should be between 0.5% to 1% of the bore of the cylinder.

If you liked this article, you may also like to read Different parts of Marine air compressor

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Latest Marine Technology Articles You Would Like:

- Compressed Air Line On Ships – A General Overview

- Marine Air Compressor Maintenance – Things You Must Know About

- The Ultimate Guide to Air Compressors on Ships

- What is Clearance Volume or Bumping Clearance in Air Compressors?

- Troubleshooting Air Compressors on a Ship: The Ultimate Guide

- Safety Features and Maintenance Procedure for Air Compressor on a Ship

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

As written above, fr adjusting the bumping clearance put a shims to the bottom bearing. By putting a shims it will hamper our bearing lubrication, as the clearances will be different from previous one. So how to manage the lubrication?

You are right that the clearance will increase. The manual specifies the limit for this and it will depend on the manufacturer. If the clearance is too much then of course we need to put oversize bearing which is also specified by the manufacturer.

Is it right to adjust clearances by adjusting gasket size between bed plate and crankcase.

Increasing gasket size reduces H.P clearance and increases L.P clearance.

Where to insert depth gauge to check bumping clearance without removing head….tanabe manual says insert depth gauge but didn’t mention exatly where

how clearance affect s the pressure ratio

Nice article, Easy to understanding and interesting to reading, Thank you