Efficiency of Air Compressor and Uses of Compressed Air on a Ship

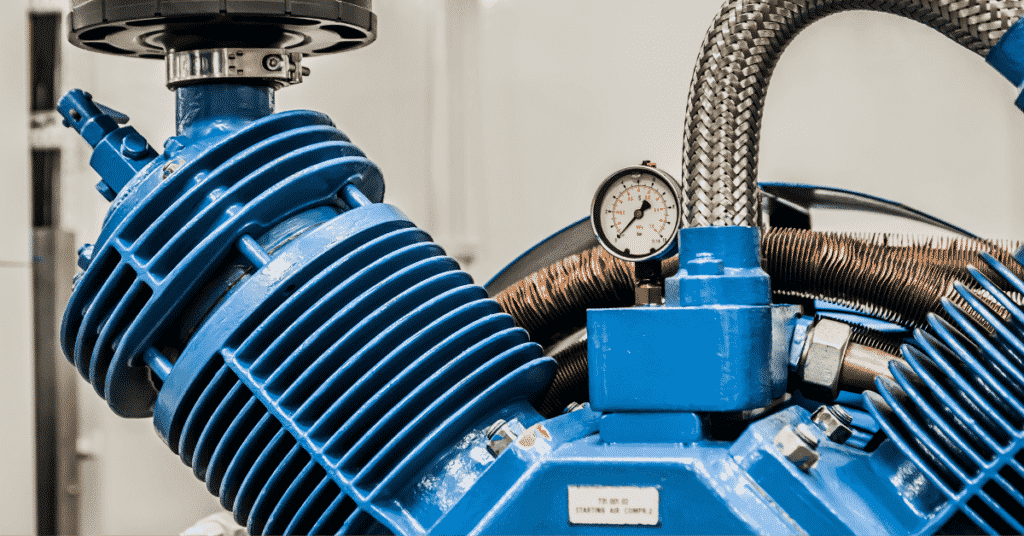

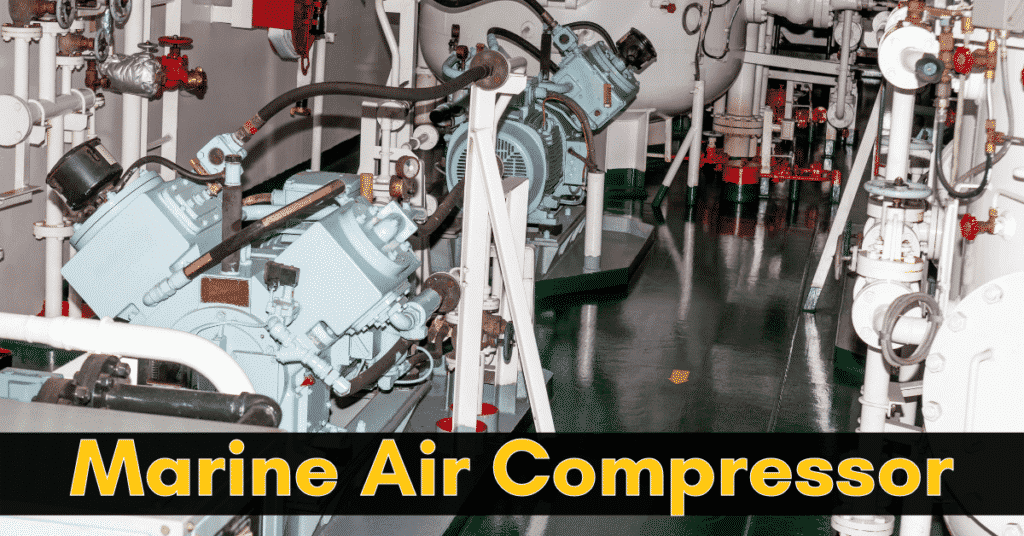

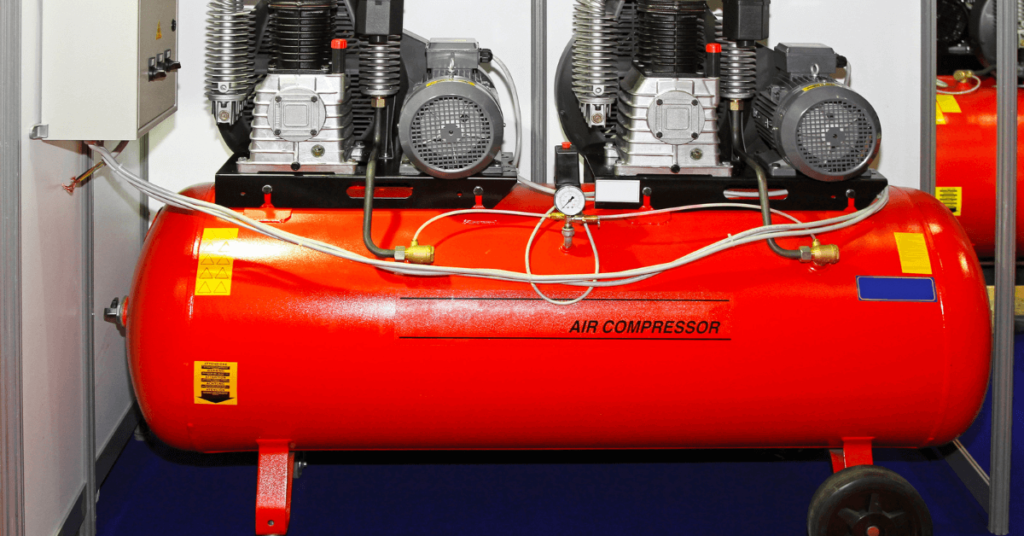

The Efficiency of an air compressor on a ship depends on several factors. A compressor provides highly pressurized air which increases the temperature to exceptionally high levels. In order to get quality performance out of air compressors, it is important to check and control the pressure and temperature within optimum range. In this article we will learn as to what it takes for efficient running of an air compressor on a ship.

Efficient working of Air Compressor

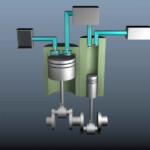

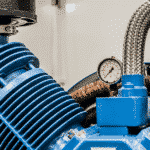

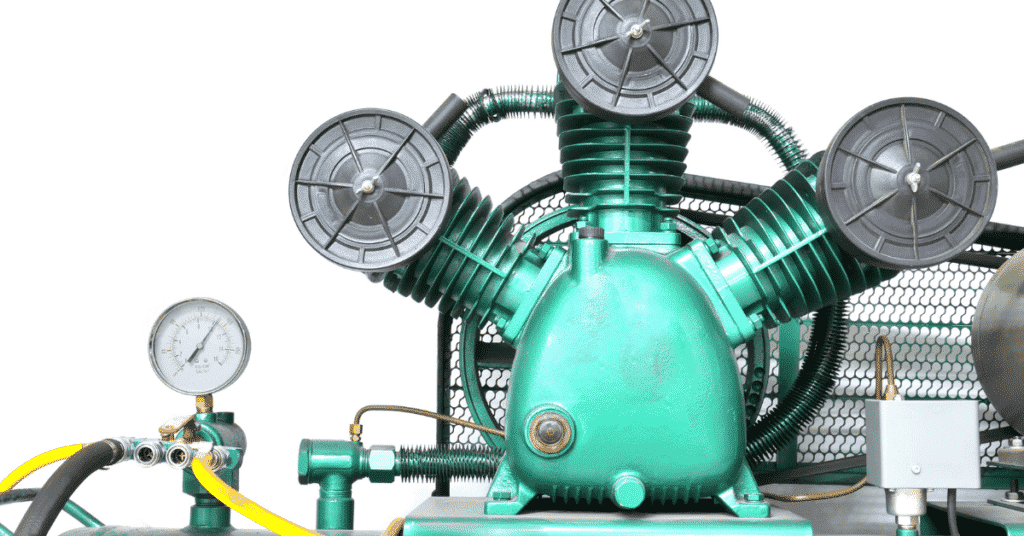

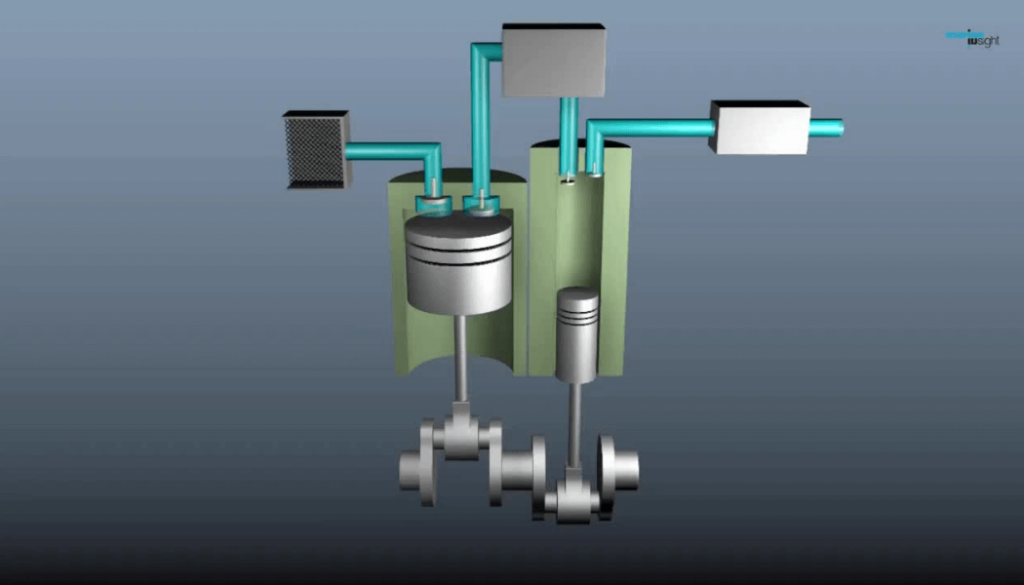

An air compressor is to provide air at high pressure. The temperature during the compression process is known as the compression temperature. The compression temperature that is generated is enough to ignite vaporized oil if present in the system. Moreover, in the process, a lot of energy is also wasted in the form of heat.

To avoid the loss of heat and overheating of internal parts, inter-coolers are fitted in the air compressor. With the help of inter-coolers, it is possible to approach the ideal isothermal compression to achieve maximum volumetric efficiency.

Sea water is commonly used for the cooling purpose in air compressor. Sea water is circulated in the system using an attached pump or by using main or auxiliary sea water circulating system. It is to note that sea water causes scale deposits in cooling passages. Sometimes, fresh water from a closed loop system is also used to avoid scale deposit problems.

Graph showing saved work due to inter cooling

Uses of Compressed Air on Ship

Compressed air is used for the following purposes on a ship.

- For starting of main engine, auxiliary engine, emergency generator and emergency fire pump.

- For automation and control air for main and auxiliary engine.

- For different application on the deck side and in engine room such as chipping, drilling, buffing, pressurized water jet cleaning etc. by use of pneumatic tools and machinery.

- For overhauling machinery by use of pneumatic tools and hydraulic jack.

- For pressure testing of different machinery parts, pipeline etc.

- Compressed air is also used for ships whistle and fog horn.

- It is used in life boat for heaving up the later, if air motor is attached as a heaving provision.

- For supplying water to accommodation and various parts of the ship through hydrophore by keeping the later pressurized with air.

- For conducting aerobic breakdowns of the on board sewage in sewage plant.

- For pressurized spray painting.

- Used in soot blowing of boiler and economizer.

- Used in portable pneumatic pumps like Weldon pumps for oil, water and bilge transfer.

- For general cleaning and services.

The above mentioned are the most common purposes for which compressed air is used. The application and uses may differ from ship to ship.

You may also like to read – Compressed Air Line On Ships – A General Overview

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Latest Marine Technology Articles You Would Like:

- Compressed Air Line On Ships – A General Overview

- Marine Air Compressor Maintenance – Things You Must Know About

- The Ultimate Guide to Air Compressors on Ships

- What is Clearance Volume or Bumping Clearance in Air Compressors?

- Troubleshooting Air Compressors on a Ship: The Ultimate Guide

- Safety Features and Maintenance Procedure for Air Compressor on a Ship

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

The waste heat could be used for hot water heating, cooking, desalination, etc.

Yes,compressor are very useful for every field,air and ship also.

how to take performance of main air compressor