What is Fendering?

Fenders are devices or entities used as guards for a vessel against impact with a jetty, dock, quay, berth, or any other ship close to a shore, preventing resultant structural damage.

Fenders act as cushions or absorbers that reduce the impact of mutual contact by absorbing kinetic energy through elastic action.

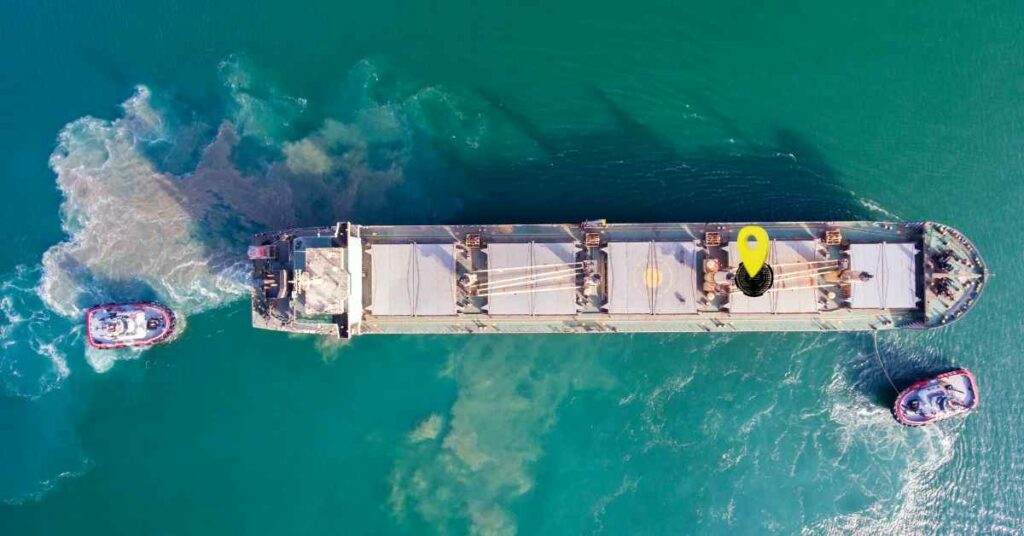

All vessels need to berth at their designated points. During this process, the ship must position itself at a definite location to serve its purpose based on the availability of space and other factors in the jetty, port, dock, pier, quay, etc.

Hence, there is a high chance of direct collision or impact of the vessel with the structure, even though the ship’s speed may be very low.

Later after the vessel is stationed suitably, the risk of contact is still highly prevalent. Though the vessel’s speed is zero after docking or berthing, the nature of the water is highly dynamic.

Thus, even a floating stationary vessel comes in contact with the shore structure now and then by the continuous inherent motions due to water currents, tides, and waves.

Moreover, at a jetty, pier, dock, berth, or quay, there are multiple vessels catering to their operations. Thus, there is also a fair chance of direct contact between the individual ships.

Furthermore, when a vessel is near a port or harbour with great traffic, the risks associated with a collision with another vessel are also high.

Also, two vessels can be berthed to each other for various utilities like bunkering or cargo transfer in what is known as Ship-to-Ship berthing (STB).

This also creates a similar situation, where two vessels are likely to collide continuously. Therefore, the question arises: Can there be any means of protection similar to bumper and mudguards in vehicles or buffers in rail cars? The simple answer is fenders.

Remember those tyre-like things on the sides of the hull and the jetty platform when you first went for your pleasure boat ride?

Those are nothing but simple forms of fendering again. From small speedboats to large cargo carriers, all vessels must have a fendering system to protect their hull structure and any shore structure or other ships from localised collisions or impacts.

However, due to the momentum of the vessel (that further depends on its size) and often continuity, the effect of these kinds of impacts may be significant enough to damage the land structure or cause high localised stress concentrations that can be enough to be called structural damage and even a localised failure for the vessel itself or any other vessel.

Factors for deciding the selection of Fenders

A type of fender suitable for one purpose may render completely inefficient for another. Hence, based on the type of vessel and the purpose.

Thus, the selection and disposal of fenders for a particular location and operation are based upon many factors.

The vessels under consideration: This is the most important factor considered. A fendering arrangement that caters to a fisherman’s wharf is completely ineffective against large cargo ships in a port. Moreover, the vessel’s type, size, and design are also crucial. For example, arch fenders are appropriate for small and medium-sized vessels.

Again, for instance, bulk carriers and general cargo ships need to be berthed right next to the jetty or quay with minimal clearance to facilitate efficient cargo transfer by maximum outreach of cranage. Similarly, passenger vessels require the same to allow safe and convenient boarding and de-boarding of passengers.

Thus, large flat fenders of suitable size and shape that are rigid and require minimum clearance gap are mostly chosen.

Modern systems also incorporate advanced types like parallel motion, sliding, or retractable extrude types that not only are capable of absorbing high values of vessel momentum over prolonged periods but also can adjust themselves accordingly based on the applied forces such that the margin of clearance between the vessel and the quay is minimal. Berthing energy is directly related to the vessel type.

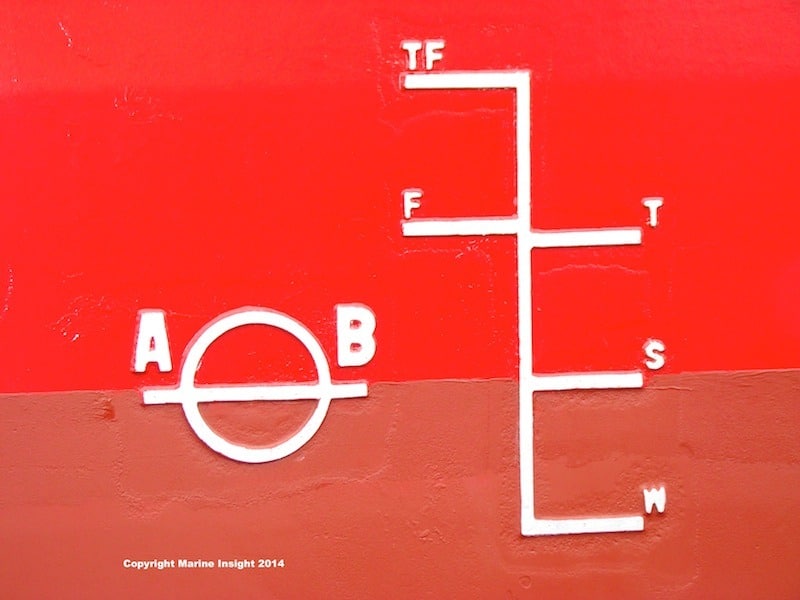

Structure and Environment: The shore structure and environment are also crucial. The conditions in which the jetty, quay, pier, etc., are subjected, like the tidal levels, wave factors, currents, and so on, are determinants of the risks of collision and the forces during the interaction.

Likewise, the type and configuration of the structure are taken into account. For instance, open pile jetties that are common for deepwater operations, load-sensitive, and have limited face area for fendering require large and highly efficient fenders that can, in lesser numbers, not only cater to high loads from large vessels but also be able to work under variable external conditions like high tides or large wave loads.

The berthing configuration and approach: Vessels can be berthed in different configurations at shore based on their requirements and design. Side berthing is the most common mode, followed by end berthing (bow or stern). There are other rare types, like a dolphin or lock berthing. Hence, when a vessel must be berthed by bow or aft, the berthing arrangement on both the ship and structure differs from when the berthing procedure is sideways.

This factor is again closely related to our first point, vessel type. For instance, when a vessel has a bulbous bow and must be berthed by the forward end, the fendering differs from a vessel without a bulbous bow. Other important factors include the approach velocity (again related to the second point of environmental conditions; rough seas increase velocities), approach angle, etc.

Types, Design, and Arrangement of Fenders

Fenders are usually disposed in a single line at more or less regular intervals at regions with the most likely influence of interactions.

On a quay wall, pier, or jetty, they are distributed at the outermost edge where there is the likelihood of contact with the vessel hull. On ships or boats, the fenders are disposed on the side shell in areas close to the waterline and the deck edge.

We know from our knowledge of conventional hull forms that when the vessel is being berthed, the land structure is most likely to strike the lower side shell part of the hull, as shown near the bilge region.

Similarly, for a ship-to-ship interaction, the most likely part of being involved is the upper part of the side shell near the deck edge, as shown.

Thus, the fenders are accordingly disposed of as required. However, for all practical purposes, fendering is optional in large seagoing ships in voyages as there is no chance of a low-scale impact in the deep sea, and fendering unnecessarily interferes with weight, stability and speed.

Types Of Fenders

Fenders can differ widely in size, shape, type, and design.

Based on shapes, some common types of fenders are:

- Cylindrical fenders

- Spherical

- Square fenders

- Corner fenders

- Circular fenders

- Cone fenders

- Doughnut fenders

- Arch fenders

- D-fenders

Depending on their mobility, there can be:

- Fixed fenders

- Floating fenders

As the name suggests, fixed fenders are fixed to a structure like a vessel or a land platform. Floating fenders are suspended on the water and allowed to float while acting as a buffer between two bodies, like vessels or vessels and a fixed structure.

Based on the construction and design, fenders can again be broadly categorised as:

- Flat fenders

- Pneumatic fenders

- Foam fenders

Flat fenders are only fitted in land structures like jetties, piers, or quays. They are mostly of rubber and have a high index of rigidity. They do not compress much and thus are suitable to sustain low momentum impacts. They are mostly circular, doughnut, square or D shape.

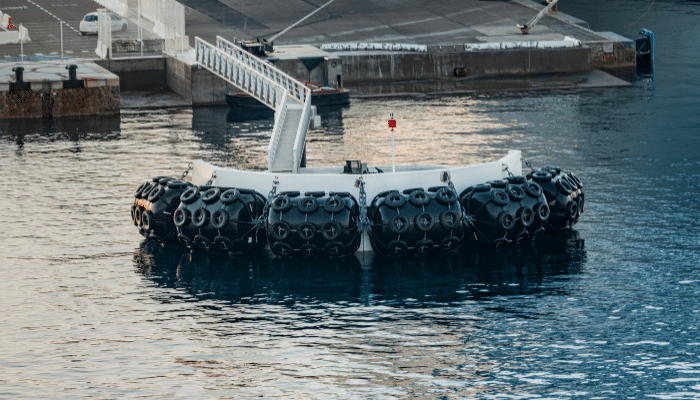

As they are mostly land-based, they are also mostly fixed fenders. Pneumatic fenders are mostly used between vessels but are often used on land when a bigger ship is involved.

These are larger and have compressed air filled in them. Thus, they can absorb a high energy value without deflecting much and have higher flexibility, something apt for situations like berthing between two floating vessels having significant degrees of freedom or for berthing large ships with a sizeable oncoming momentum involved. They are primarily cylindrical or spherical.

They are mainly under the category of floating fenders, as they can float because of their pneumatic nature. Foam fenders are similar to pneumatic fenders and can float because of their construction. They have an inner foam core and an outer shell of synthetic polymers or elastomers. Another added advantage of foam polymers is that they cannot deflate when punctured.

Nowadays, mechanised fenders that are adjustable and retractable based on loading pressures are also common. Leg-type, extruded, sliding and parallel motion fenders are some important ones.

Design factors

Berthing energy: This is the most crucial parameter for fendering for designing fenders. Berthing energy is the kinetic energy of the impact load when it is transferred from a vessel to a berth or between two successive vessels.

Now, as we know, the kinetic energy of a body is measured as ½ X mass X velocity square (1/2 X m X v2 ). When a vessel is imposed on a fixed structure like a berth, this mass is simply the vessel’s displacement. However, when two vessels interact, the effective mass is given by M1 X M2/ (M1+M2), where M1 and M2 are the masses of the two bodies.

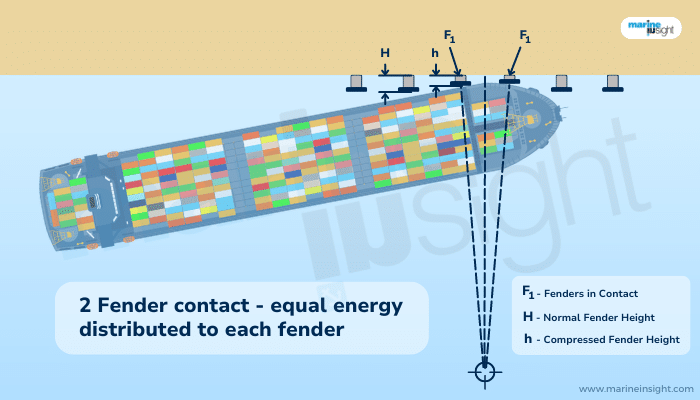

Fender spacing: The interval between 2 successive fenders. This depends on the type of vessels, the environment, and the berthing types.

Fender Contact: This is the force shared by each fender. This is again related to the berthing configuration and the vessel type. As we discussed above, for instance, when a vessel is side berthed, the forces on the fenders Are more or less uniform compared to when it is at an angle dolphin berthing or berthing between two ships when the entire loading cycle is highly dynamic.

Materials

As discussed above, the material for fenders depends on their type. For example, the inner core is foam in foam fenders, and the outer core is elastomers. Flat fenders typically use polyethene, rubber, and sometimes steel additives to improve strength and rigidity.

Pneumatic ones use plain rubber (like tyres) and monomers. PVC is also a very commonly used material. Mechanised fendering uses mostly steel with rubber paddings at the points of contact. The material is selected based on strength and operational requirements.

You might also like to read-

- The Design Of Modern Ship Masts – A Quick Overview

- What is a Skeg in a Vessel?

- Understanding Working of Hovercrafts

- Types of Sailboats – A Comprehensive Classification

- What Do You Understand By Prow Of A Ship?

Do you have info to share with us ? Suggest a correction

About Author

Subhodeep is a Naval Architecture and Ocean Engineering graduate. Interested in the intricacies of marine structures and goal-based design aspects, he is dedicated to sharing and propagation of common technical knowledge within this sector, which, at this very moment, requires a turnabout to flourish back to its old glory.

Latest Marine Navigation Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.