What is Container Depot – Purpose And Design

The shipping industry represents the single largest volume of trade, amounting to nearly 90% of global commerce.

With trillions of dollars in the maritime transport industry, goods and commodities often cannot be simply transported in loose condition.

They must be arranged in a specific manner that protects them from damage and natural motions of the ship.

This is where shipping containers come into play.

Unlike oil, fluids, gases or grain, certain goods are grouped on pallets and then stored in large containers.

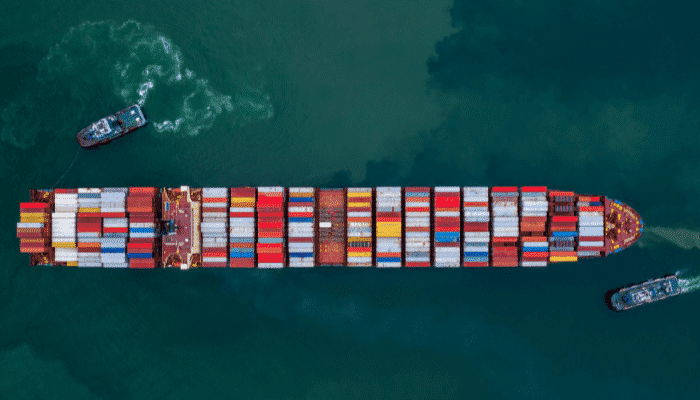

An average size container ship carries approximately 15000 – 20,000 containers, each with a capacity of holding anywhere between 30,000 to 60,000 litres worth of goods. This translates to an enormous amount of trade volume per ship.

Moreover, unlike other types of vessels, container ships are versatile and can carry a wide variety of goods, since the only constraint is that they must fit inside the containers. These factors make containers ships ideal for transporting goods and commodities.

The next question that is raised, is where these containers are to be stored while not on ships. It is impossible to have every single container pressed into service at any given point in time.

Loading and unloading of goods can take long periods of time that require the container to be stored in a safe and permitted place until it takes on its next assignment.

Most companies do not have the adequate space to store an entire container consignment, and can only collect the goods within it.

Thus, there must a central facility where these containers can be stored while they are in a state of transit. This facility is known as a container depot or a container yard.

What is a Container Depot?

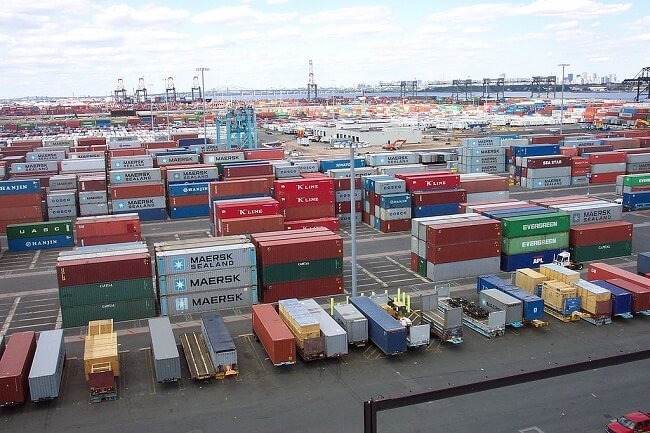

A container depot or yard is where several containers are stored or held in transit, once they are unloaded. This depot provides a single place where shipping and logistics companies can keep their containers until it is time for reloading.

A common misconception is to consider that storage facility for fully-loaded containers is also container depots. In fact, those are merely holding facilities or terminals, and are temporary in nature since shipping companies aim at transferring the goods to the receiving party or to the care of the port at the earliest.

Once containers have been unloaded, they are trucked back to the depot, where they are registered by company officials. In general, the depot is located inside a port or terminal or in the surrounding area. This enables for a quick and immediate transfer of containers between different locations.

These container depots and yards are secure facilities that provide basic essential services for the container shipping companies. These are covered in more detail later on.

It suffices to say that containers are often kept for protracted periods of time entailing maintenance and frequent checks. The yard/depot provides a single place from where these services can be carried out.

In addition to a container depot, there are also container ports and terminals. Container ports are those ports that primarily deal with the shipping of containers through carriers.

Shanghai and Rotterdam are major container ports that see billions of dollars’ worth of trade every day. They are often subset entities of larger ports but deal specifically with goods.

Container terminals, on the other hand, are facilities where loaded containers are held before “transhipment”. This is a term that indicates transfer between different modes of transport.

For instance, once unloaded from a ship, the container can be then moved onto another vessel, known as maritime transhipment. Or, it can be loaded onto a truck for transport by road or rail, which is known as inland transhipment.

These container terminals are located inside ports in most cases, as they allow for better logistics when it comes to transhipment. Container depots, on the other hand, do not have any such prerequisite.

They are located near ports merely to receive the benefits that come with being located near them. They might also belong to the port, and so are located nearby.

Functions and Uses of a Container Depot

Container depots serve multiple uses and ensure a smooth flow of commerce between various countries and ports. One of the major issues that they solve is the holding of empty containers after unloading at the receiving party’s warehouse.

Ideally, each container company should provide its own secure facility for storage, where they can keep track of their containers in different locations. However, this creates a major crunch in space around the hinterlands surrounding the port.

Thus, an idea was born in the mid-19th century, where ports or other private entities offered a single location with nominal payment rates, for storage of containers.

Almost all the major shipping companies in the world from American Shipping Lines and Maersk to Hapag-Lloyd store their containers in such secure facilities.

One advantage of having these depots is that they allow for easy logistics between ports and other depots. They serve to solve the problem of bottlenecks and storage issues.

For instance, an average ship can move 20,000 containers from Rotterdam in Europe to Shanghai in the far East. This creates a shortage of containers in Rotterdam, while there is a surplus in Shanghai. To balance this, Rotterdam requests for containers from nearby depots.

Once supplied, Rotterdam reaches its baseline value of containers. The surrounding depots that supplied it again request for containers from their nearby depots, and this cycle continues until an equilibrium is reached.

Finally, at the end of the cycle, the depot at Shanghai port supplies a neighbouring depot with its surplus containers, which terminates the process.

The situation where there is a large surplus of containers in one location, but a crunch in another place is known as a shipping bottleneck. This often arises from improper planning in the logistics phase of shipping.

Container depots are integral in solving the bottleneck crises that arise frequently in the shipping industry.

Another essential function of container depots and yards are the auxiliary services that they provide.

Enterprising depots often offer a wide range of services to their clients. This is in the form of cleaning, repair, maintenance, protection, fumigation, transportation etc. They provide an alternative to individual shipping companies having to maintain and handle their empty containers.

Most depots have facilities that clean and regularly fumigate the containers. This is because the chance of mould or organisms entering and breeding in the container are highly likely, especially during long voyages. Thus, regular care is to be taken of the condition that the container is maintained.

Another function is the repair of broken or damaged containers. When lashings come loose during transport, the goods within may damage the container. This could range from small scale dents to a major overhaul.

Thus, instead of having to ferry the container to the company facility, it can be repaired for a nominal fee at the depot itself. Maintenance is another important service provided by container yards.

Reefer boxes often need their cooling systems to be regularly maintained so as to prevent a risk of short-circuiting in the middle of a journey. Along with all these services provided at yards, they sometimes offer incentives such as free transport and pick up between locations.

For instance, companies often unload their goods using trailers that they hire. However, when yards provide pick up from the warehouse, the shipping company does not have to pay for the additional services of the trailer.

Related Reading: Freight Forwarder Vs Supply Chain Professional – What To Choose?

Layout and Design of Container Depots

Container depots must have a standardized layout that promotes security, while also providing sufficient space for storage. A major issue that plagues storage units and other similar facilities is that providing security for large units can be difficult.

Pilfering machinery from containers such as the refrigeration unit of reefers is a major problem. In addition, if not properly checked, illicit goods could be trafficked through the containers.

Most depots have large boundaries with points of entry and exit that are manned round the clock. Some depots have facilities that test for trace amounts of drugs and other substances in empty containers. This helps officials pinpoint and stop methods of smuggling.

Inside the boundary, most containers are piled high in the air using straddle carriers, or large spreader cranes. These are capable of lifting containers to large heights and stacking them in order of arrival and departure.

Some yards also stack containers by the company they belong to. Thus, there may be a separate region for each company, and the location and size of this region are often allocated through bidding.

Arranging containers is important, as it affects the turnaround time between demand and supply. For instance, if all the Twenty-foot Equivalent Unit (TEU) containers are located at the bottom of a stockpile, then all the units above them will have to be removed. This is a considerable waste of time. Instead, efforts are made to have as small a turnaround time as possible, by ensuring efficient stacking.

Lastly, offices and other service providers generally occupy the periphery of the container depot. The entire depot is connected using an extensive road and rail network.

Large facilities often have an in-house rail connection that is used to bring and send containers. Some yards also have a customs office that oversees loading and unloading of containers, along with the regular inspection.

Conclusion

Container depots are an ideal case study of logistics and operations management. They showcase the steps that can be taken to overcome important problems such as bottlenecks and lack of space.

By offering a centralized facility for the collection, storage and maintenance of containers that are not currently in use, they can be used to boost the revenue of ports in the vicinity.

In addition, they also help establish ports as innovative and user friendly. The bottom line is that container depot create an interim holding facility that combines several useful services in a single place.

You might also like to read:

- What is Demurrage and Detention in Shipping?

- 16 Types of Container Units and Designs for Shipping Cargo

- What is Merchant Haulage?

- What is OOG or Out of Gauge Cargo?

- A Guide to Shipping Container Dimensions

- What is a Logistics Cycle?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Maritime Knowledge Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

Ajay Menon is a graduate of the Indian Institute of Technology, Kharagpur, with an integrated major in Ocean Engineering and Naval Architecture. Besides writing, he balances chess and works out tunes on his keyboard during his free time.

Hello, dear Ajay Menon.

I am a naval engineer from Colombia, studing an MBA, in my final work, I am analzing the container depot efficiency, I really appreciate if you have information about how to create a container depot