17 Pro Tips For Efficient Marine Growth Prevention System (MGPS) On Ships

The Marine Growth Prevention System (MGPS) has been developed for ships with the sole purpose of tackling marine organism growth, preventing it from depositing on the ship’s interior piping systems, which are continuously supplied with sea water.

Related Read:

The anode in the MGPS system generates ions that spread in the seawater system, producing an antifouling and anti-corrosive layer over the internal sides of sea pipes, heat exchanger (i.e. coolers and condensers), valves in seawater system, refrigeration systems, AC units etc.

The three types of alloys used for anodes are:

Copper Alloyed Anodes: This is the most used type to prevent marine fouling in piping, strainers, heat exchangers, pumps etc.

Aluminium Alloyed Anodes: This type is used in conjunction with copper alloy anodes to prevent corrosion throughout the ferrous piping system.

Ferrous Alloyed Anodes: They are used in conjunction with copper alloy anodes to prevent corrosion throughout Cu/Ni pipework.

Related Reading:

Understanding Sacrificial Anodes on Ships

An MGPS system can be installed on the ship in following ways:

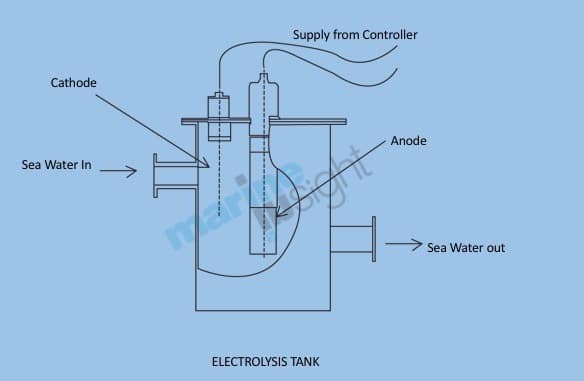

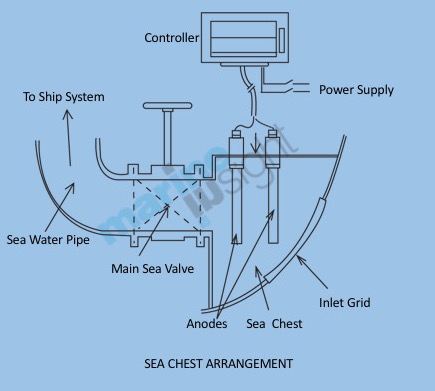

Anodes Mounted on Sea Chest: They are commonly installed in new buildings and have a working life such that they can run till the next drydocking.

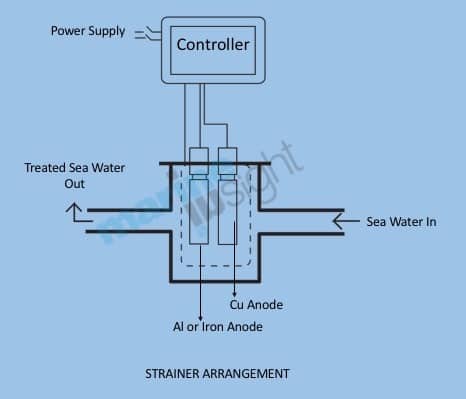

Anodes Mounted in strainers in the seawater pipeline: They have an advantage of replacing the anodes without affecting the seawater supply to ship’s system.

Treatment tank setup with a spray nozzle in sea chest: In this system, a separate electrolysis tank with anodes is installed which sprays the ion through the nozzle in the sea chest. This system is installed on ships where sea chest or strainer mounting is not possible.

Related reading:

4 Types of Anti-fouling Systems Used on Board Ships to Prevent Marine Growth

With the MGPS functioning efficiently, the systems using seawater will have following benefits:

- Marine organisation growth on the surface of pipe or valve will decrease the flow. MGPS helps in maintaining a good seawater circulation

- Eliminating corrosion in the pipelines

- Increasing the cleaning duration of the seawater system which will be very frequent in the absence of MGPS

- Maintain the efficiency of the system and machinery supplied with seawater

- MGPS adds to the energy savings of the ship

Here are 17 tips to ensure Marine Growth Prevention System (MGPS) always provide the top-notch performance to get the benefits stated above:

1. Ensure there is no aluminium pipes or parts attached to the seawater system in which MGPS copper anodes are connected. In a copper-based anode or MGPS systems, the aluminium will have a chemical reaction and act as an anode in the vicinity of copper, leading to severe corrosion of aluminium parts

2. The current settings for the MGPS should always be maintained as prescribed by the maker. A high current value setting will lead to a shorter anode life, and a lower current setting will increase the anode life

3.The typical current value on which the majority of MGPS anodes work comes in the range of 0 to 2 amps per anode. This value can be manually adjusted in a range of 0.2 amp steps

4. When the MGPS is installed on a non-ferrous metal surface (e.g. pipe upstand), the installation flanges of the anodes must be provided with an isolation material to ensure there is no electrical contact between the anode and non-ferrous surface, i.e. between two dissimilar metals

Related Reading:

How to Identify Metals in Engine Room?

5. When the MGPS anode assembly is installed on the strainer (the anodes usually are installed on the strainer lid), it is essential to correctly place the anode inside the strainer basket in such a way that the anode surface does not touch any metallic components

6. Whenever the strainer is opened up for inspection or cleaning by lifting the lid, ensure to disconnect the supply of these anodes and not to damage them when removing the strainer basket lifting bar

7. When the MGPS anodes are installed in a sea chest, ensure they are not placed in the “dead zones”, i.e. where the water flow is minimal. They should be mounted in the central passage of the seawater flow from the inlet grids to the seawater suction

Related Reading:

General Overview of Central Cooling System on Ships

8. Ensure not to use oversize cables for the MGPS anodes as they are likely to cause mechanical overload on the terminal blocks.

9. Under daily watchkeeping duties, check the digital display ammeters are working properly. When an anode has nearly consumed, the corresponding display will show a low value.

Related Reading:

12 Ways to Master the Engine Room Watch Keeping Procedure

10. If the anode current value is dropped to a low level, turn off the current knob to zero, i.e. no supply to the anode and renew the anode at the first chance. After renewing the anode, reset the current to the previously given current settings

11. For treatment tank type MGPS, open the air vent on a daily basis to prevent air pockets inside the tank

12. When replacing or renewing the anodes, ensure to carefully unscrew the mounting nuts to prevent the anodes falling down the sea chest, which may damage the chest or the anode itself

While drydocking of ships, the MGPS anodes are normally opened up for overhauling and checks as no water is present in the sea chest.

Following points to be considered when working on MGPS system in drydock:

13. While opening the anode, never lift or support the anode from its cable or apply any mechanical load to anode cable.

14. The new spare anode which is of held-in type or flange sleeves type is supplied unpainted with a rust prevention coating. Ensure to remove this coating before the installation. Never use a wire brush or mechanical instrument to remove this layer. White spirits or turpentine can be used for the removal of this coating.

15. If anodes are installed in a space where blast cleaning or painting is not finished, they must be suitably protected. Before flooding the spaces, check to ensure that the protection has been removed. Also, remove any paint, tape adhesive residue or grease from the anode surfaces.

16. Ensure the renewed anodes are mounted in the vertical position unless otherwise stated by the makers or manufacturer.

17. During dry docking for retrofit systems, before the vessel is launched or refloated, check the isolation of each anode from the hull, as well as continuity of the positive feed circuit to the anode

The MGPS installed on a ship must be effective against a large variety of organisms due to the multiple numbers and complex nature of fouling communities present in waters of different parts of the world the ship ply to.

Any antifouling agent used within the MGPS must comply with the local and international regulations and requirements, particularly about biocidal discharges.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

good day i don’t understand there is reccomendation to use Aluminium Alloyed Anodes with copper alloyed anodes together, but i read down from 17 tips that there must not be working together ……> Ensure there is no aluminium pipes or parts attached to the seawater system in which MGPS copper anodes are connected. In a copper-based anode or MGPS systems, the aluminium will have a chemical reaction and act as an anode in the vicinity of copper, leading to severe corrosion of aluminium parts.please explain i don’t catch your points?

Anodes are meant to react to safeguard. However, when it comes to parts and piping system they should not react. As mentioned – In a copper-based anode or MGPS systems, the aluminium will have a chemical reaction and act as an anode in the vicinity of copper, leading to severe corrosion of aluminium parts