Understanding Water Jet Propulsion – Working Principle, Design And Advantages

Ships are enormous structures, weighing anywhere between 100000 tons and 500000 tons. Yet, they are moved with ease across the earth’s oceans.

At the other extreme of the vessel size spectrum, small fishing trawlers and pleasure yachts barely weigh over 10000 tons. They are commonly found speeding along the coastline at very high speeds.

So how are such different vessels and boats powered across water?

This is where marine propulsion comes into the picture.

Different vessel classes utilize various propulsion systems that use several techniques for generating power. Earlier vessels used fossil fuels such as coal to run large engines powering propellers.

Later models worked using reciprocating engines and diesel-run marine engines that were more efficient. Nuclear power is also used nowadays to power warships but is far too expensive and dangerous to be adapted into the commercial shipping sector yet.

Wouldn’t it be convenient if some form of power could be generated using an easily available commodity that does not create toxic products?

This is where water jet propulsion comes into the picture.

Water is the most abundant resource present on earth, with nearly 75% of the earth covered with water bodies. In addition, when used as the sole propulsion component, no harmful by-products are created, and the entire process is environmentally friendly.

In this article, we will take a look at water jet propulsion, its working principle, and the advantages that it poses.

Conventional Marine Propulsion Systems

Propulsion refers to the mechanics behind generating thrust and force that can be used to move a body under its own power. The required power is conventionally produced using two or more marine diesel engines that work on either two or four-stroke modes.

These engines have several piston cylinders that generate rotational motion through the combustion of the fuel at ignition temperature. The rotational motion is used to rotate a crankshaft that is connected to the marine propeller shaft that leads up to the propellers.

Propellers have hydrodynamically shaped blades numbering three or more, that force water behind the ship to propel it forward. The engines are placed on strong shock-absorbing platforms capable of redirecting vibratory motion into the large surface area of the hull.

To alter direction, rudders are used to direct the incoming fluid mass from the propellers. In newer azipod designs, the rudders are integrated into the propellers, resulting in a compact system that can rotate in most directions to change the trajectory of the vessel.

From the above description, there are several problems that can be identified. The main disadvantage of this conventional system is the dependence on a large number of components, that are not easy to replace.

For instance, if the marine propeller shaft requires repair, the propellers and entire shaft assembly have to be removed from within the ship, at great cost to time and labour.

A simpler design would allow for repairs to be performed faster, by allowing various components to be more accessible.

Water jet propulsion has this benefit, as it is built into a compact system that can be taken apart without having to dismantle a large part of the ship.

Now that we have a proper understanding of the method in which conventional propulsion works, we can better understand water jet systems and the advantages they come with.

Water Jet Propulsion

Using water as a source of power eliminates several problems arising out of conventional propulsion methods. It’s fast, quiet, and extremely environment friendly.

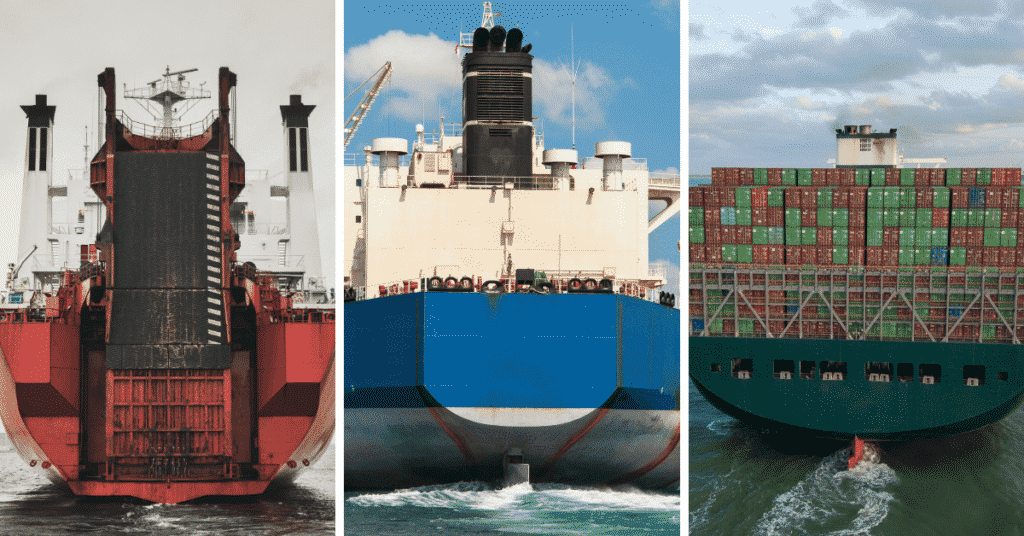

Nevertheless, water jet propulsion cannot be used for large ships such as tankers, cargo carriers, or warships at present. It is more suited to powering smaller coast guard and naval vessels, trawlers, tugboats, and personal vessels.

The idea of using water as a source of power was first considered as early as 1661, by Toogood and Hayes who theorized that a central water channel could be used to generate propulsion. The idea went through several iterations before it was widely accepted and integrated into commercial vessels.

Several commercial enterprises design, construct and install water jet systems. The main difference in these companies is the installation components, the degree of movement, working component design, and material choice.

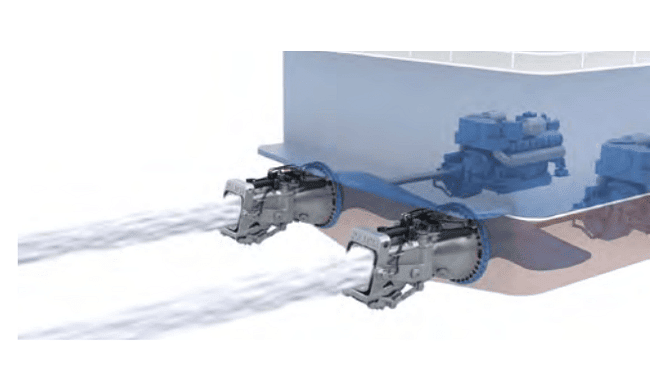

Briefly put, water jet systems are placed at the stern of the vessel, near the waterline. Water is drawn and processed within the system to exit the aftmost nozzle at a high velocity that propels the vessel forward.

In the next section, we will analyze how this system works and the physics behind water jet propulsion.

Working Principle, Mechanism, and Components

The water jet system operates on the principle of Newton’s Third Law which states that every action has an equal and opposite reaction.

The force developed due to the rapid ejection of water from the aft nozzle of the water jet system creates a reaction force that propels the vessel forwards.

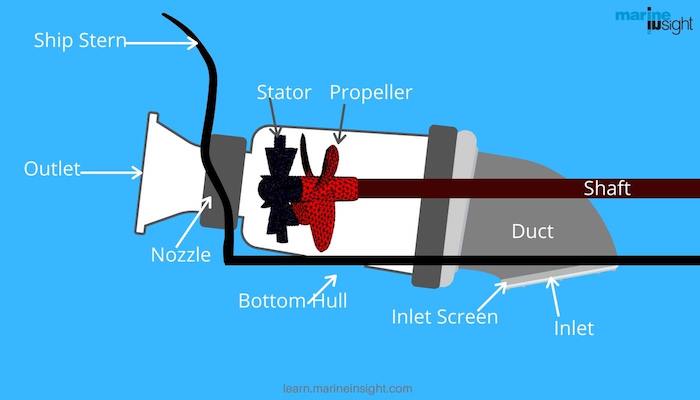

The water is directly fed into the main machinery through a suction duct located on the underside of the vessel.

Most vessels use only a single duct, although a higher number of ducts can increase the power generated which is required in large vessels. The fluid passing through the inlet is directed through the main processing unit of the system.

In case of any blockage due to debris near the inlet, the vessel can be stopped until the debris is cleared. Other mechanisms are present that can backflush the inlet so that the debris is dislodged.

The inlet water is a relatively low energy fluid since it is at rest prior to suction. However, in order to create sufficient thrust, it must be converted into a high energy fluid. This is accomplished by inducing an element of turbulence using blades. The blades are powered using an impeller and stator arrangement.

Due to fluid mechanic responses, sufficient pressure is created using this turbulence and is then ejected as a high-pressure jet from the nozzle. The impeller is a shaft that is powered using an onboard motor. It is coupled to the stator that rotates the blades.

To understand the impeller-stator arrangement, it can be likened in principle to the engine of an aeroplane that rapidly increases the outlet velocity of air entering the turbine. The impeller shaft is rotated by the main drive shaft connected to the motor and is coupled using reinforced bearings and connectors.

The nozzle is located at the aft of the unit and directs the fluid leaving the system. It is controlled by a swivel system that is connected to a steering wheel in the bridge of the vessel.

The swivel motion extends anywhere between 150⁰ to 180⁰ on most vessels. There is an essential component known as the astern deflector that aids the vessel in moving in reverse or taking turns while in reverse.

The deflector is designed using a hydrodynamical shape that is able to smoothly redirect flow in the opposite direction of ejection. It fits over the mouth of the nozzle and can be lowered or raised depending on the steering manoeuvre required.

The powering of moving components on the unit is provided using two main sources-

- the onboard motor for the impeller shaft, and

- hydraulics for the deflector operation.

The hydraulics are generally oil-based and are stored within the hull of the vessel, to prevent any form of pollution in case of an oil spill.

To access the various components of the vessel, several access panels are provided throughout the length of the unit. However, care must be taken while opening the system, and the entire unit must be powered down and brought to a complete standstill.

Due to the large vibrational shocks and forces acting by the propulsion system, the unit is mounted on specialized structures that can redirect and absorb the output forces. The force is redirected into the large hull surface area so that it may safely be dispersed without creating dangerous point loads.

How are Water Jet Crafts Operated?

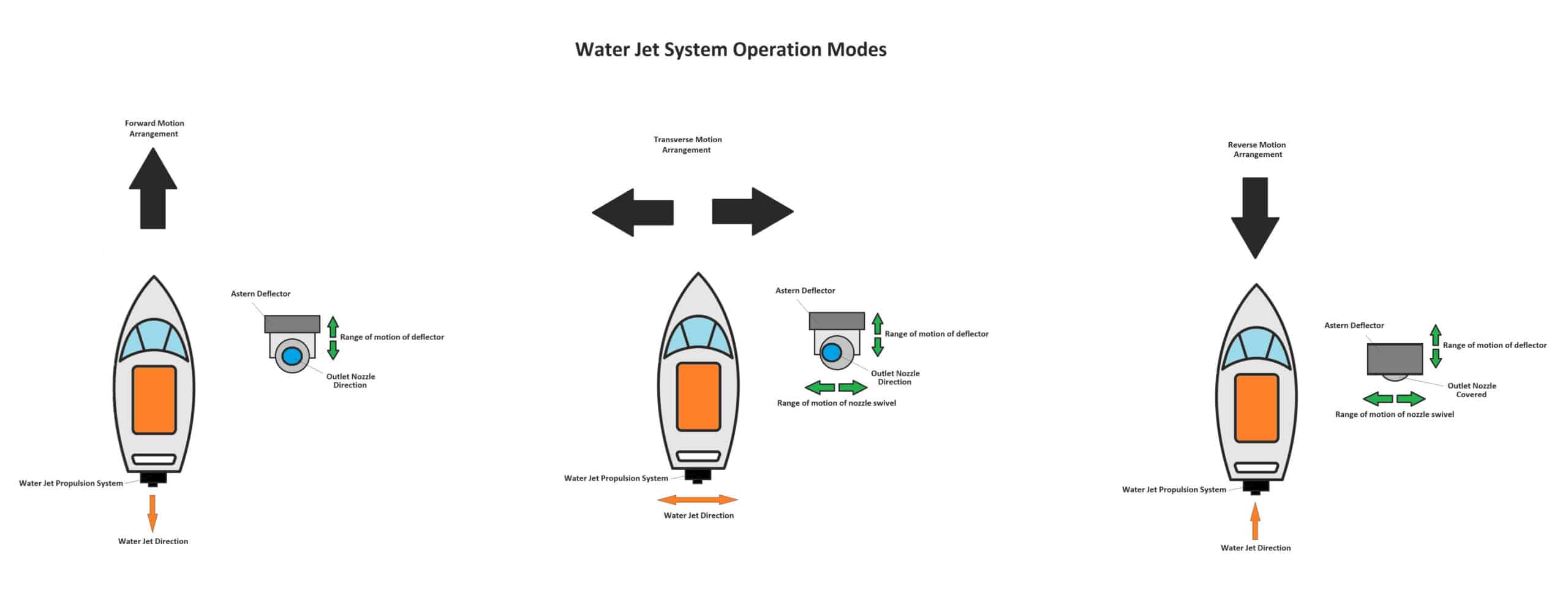

Water jet systems are extremely precise and accurate when it comes to manoeuvrability and steering. This is because of the incredibly wide range of motion that is provided by the nozzle.

The main controls available to the officer in charge of steering includes a throttling lever, a steering wheel, and a lever to lower or raise the astern deflector. We will look at some primary steering operations and how water jet technology accomplishes the same.

For acceleration in a forward direction, the throttling lever is gradually increased with the deflector kept in a raised position. In this condition, the thrust generated by fluid exiting the nozzle is directed in an aft direction, thus propelling the vessel forwards. By adjusting the throttling lever, the speed of the vessel can be changed as the fluid exits at faster rates.

For turning operations, the steering wheel is used in conjunction with the throttle. The direction is controlled by the wheel, while the rate of turning is subject to throttling. To obtain tight turns, high throttle and sharp rotation of the wheel are required. Depending on the number of units and power generated by each unit, the speed of turning can vary depending on vessel size and weather conditions.

Lastly, for reverse, the astern deflector is lowered and the throttle increased. As the throttle increases, the water jets exiting the nozzle are redirected downwards and in a reverse manner using the hydrodynamic shape of the deflector. This causes the vessel to move in a reverse direction.

To turn while reversing, the wheel is used to change the direction of the water jet leaving the deflector. While steering, it is good practice to remember that the bow always points in the direction in which the steering wheel has been rotated. This helps especially when reversing, as the turning convention is flipped in this situation.

The number of units in use can have a major effect on the efficiency and effectiveness of the water jet system. Although using a single system is common, a dual system arrangement is preferred. This is because it provides a higher degree of control.

For instance, to keep the vessel stationary, a combination of the forward and reverse modes can be used. The deflector is lowered partially such that half the thrust is allowed to pass through, while the remaining half impinges off the deflector and provides reverse thrust. In this situation, steering is still active.

Rotating the wheel allows the vessel to take a turn with a turn radius of nearly zero, i.e., the vessel executes a turn about its current position. Advances in water jet technology have allowed for even single-unit systems to execute this manoeuvre.

Similarly, the vessel can move transversely without any translational motion using dual units. This is achieved by using individual jets in different directions to keep the vessel steady. If the arrangement is not properly handled, the vessel can rock violently, resulting in parametric resonance and eventual damage to the vessel. It may also cause damage to the dock upon collision.

An interesting point to note is that water jet units can come in three main variations at the time of fitting-

- the standalone unit,

- separate duct and nozzle,

- or a separate duct.

The preferred metal for construction of the nozzle is steel, while either composites or steel are used for the duct. Having a complete standalone unit allows for easy installation since the entire system simply needs to be connected in a dry dock.

Advantages and Disadvantages

Water jet propulsion has several advantages that make it an attractive choice when choosing propulsion systems. Speed of vessel is very important when it comes to small crafts, and water jet-powered boats are able to reach 40 knots (75 kmph) even in poor conditions. This is comparable and often higher than conventional industry standards.

In general, to reach high speeds, conventional propellers blades have to rotate at very high RPMs to generate sufficient thrust. However, this results in a dynamic pressure difference between the surrounding medium and the edges of the rotating propeller blades. This causes disintegration of the edge due to a phenomenon known as cavitation.

Cavitation is caused due to water that rapidly vaporizes near the blade surface resulting in microbubbles that damage the edge of the propeller blade. This effect can quickly wear through metal and force the vessel to move in unpredictable directions.

Although water jet systems also use hydrodynamic blades, there is a smaller dynamic pressure difference between the internal machinery and surrounding fluid. Thus, the effects of cavitation are considerably reduced. This results in a longer working life of the system.

The water jet system is very compact and is able to produce a considerable amount of power within a small unit. This makes it a good choice in vessels with space constraints.

The propeller blades are covered with a shrouded design, that prevents any accidental contact with the high-speed blades. Thus, it is safer than conventional blades that are not shrouded. Another advantage of using water jets is that the entire assembly does not need to be submerged.

For normal systems to be effective, the entire blade and shaft assembly must be submerged, whereas only the inlet needs to be submerged in water jet systems.

Water jet propulsion is also easier to manoeuvre since steering is almost instantaneous. This is because of the immediate response of the hydraulic systems that swivel the outlet nozzle.

Unlike conventional vessels that require a larger turning radius, water jet-powered vessels can execute a complete 360⁰ turn while remaining at a fixed position. In addition, turns can be executed at a much faster rate by simply increasing the throttle provided to the water jet. Thus, steering and navigation are considerably faster and more efficient.

Another benefit of water jet systems is the lack of a gearbox. Although this presents a higher level of control in standard propulsion systems, it is unnecessary when it comes to water jet systems. This is because only a single gear mode is utilized, and there is no need to change the torque of any rotational component. The only rotating component is the impeller that is connected to a basic rotational coupling. Thus, lesser components need to be serviced and repaired in water jet systems.

Lastly, from a military aspect, water jets do not produce as much noise as compared to conventional propulsion. This translates into reduced physical noise, and reduced SONAR signatures. This has immense application in military-grade vessels that can travel at high speeds without being easily detected by SONAR and other systems. This occurs in part due to the shrouded design of the assembly, which redirects and redistributes noise.

The main disadvantage of water jet systems is the high initial costs that they pose. Unlike standard propulsion systems, the components and machinery associated with this technology are still far too expensive to be integrated into all vessels. In addition, the cost of installing and maintenance can be steep owing to the specialized nature of the process. Thus, most boat operators and owners prefer to go for cheaper alternatives.

Another issue faced by water jet systems is that they can only be used in the cases of small and medium vessels. This is because the amount of thrust generated by standard equipment sizes can only achieve sufficient thrust for vessels of these sizes. Larger vessels would also require the propulsion systems to be proportionately larger.

It is not that it cannot be achieved in the near future; it is simply far too expensive to execute this type of manufacturing. In addition, constructing components of a size comparable to conventional propellers requires specialized equipment that is still being researched and developed by commercial entities. In the near future, we can expect a gradual increase in the number of vessels being powered by water jet propulsion due to lowered production costs.

Do you have info to share with us ? Suggest a correction

About Author

Ajay Menon is a graduate of the Indian Institute of Technology, Kharagpur, with an integrated major in Ocean Engineering and Naval Architecture. Besides writing, he balances chess and works out tunes on his keyboard during his free time.

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

The introduction is misleading as you highlighted pollution and by using jets you can eliminating marine pollution…incorrect. Propellers are turned by diesel engines similarly jet impellers are also turned by diesel engines; so there is pollution. After mentioning coal, diesel and nuclear, I thought you would have introduced gas (LNG) engines or even HHO generation (hydrogen) then move on to jets.

I find MI articles very informative and nicely explained.

Hi Tulsie

Thank you for your comment and concern. We do have articles on LNG and other friendly fuels. ??

Hi. Can an off the shelf electric submersible borehole pump strapped under a boat hull be used to power a boat?

How do I calc the pump delivery volume, outlet diameter and pressure required to move a 2 ton boat at 10 knots?

Thanks very much. I Love It