Why Dry Ice Is Used For Packaging

The solid form of carbon dioxide gas is commonly known as Dry Ice. One, which is a colourless and odourless gas, and the other, its solid form, share the same chemical formula as CO2.

Often referred to as a wonder agent, dry ice has myriad uses. In logistics, it is used in packaging to preserve frozen foods, especially during transport where other forms of cooling arrangements or mechanisms are unavailable.

Many temperature-sensitive pharmaceutical drugs and biological samples are packaged in dry ice during transport. Dry ice, which is non-toxic, maintains the cold chain during the movement of such items. Unlike ice, which is made by freezing water, dry ice leaves no wet patches on the packages.

Properties of Dry Ice

Let us go through a few important features of dry ice before we see how useful it is in preserving temperature-sensitive items.

Dry ice is colourless, odourless, and non-flammable. It has an extremely low surface temperature of −78.5° Centigrade (−109.2° Fahrenheit).

At normal atmospheric pressure, it directly changes from solid form to gas at temperatures lower than −78.5° Centigrade. This process is called sublimation. The very low sublimation temperature makes dry ice ideal as a cooling agent in packaging. However, it is the same property that makes it dangerous to humans if not handled correctly.

Handling Dry Ice

Unprotected and prolonged exposure to dry ice, especially in confined spaces, can cause a condition called hypercapnia, where the carbon dioxide level in the bloodstream shoots up. If left untreated, hypercapnia can lead to respiratory failure, convulsions, or even death.

If handled incorrectly, dry ice can cause severe burns to the human skin, similar to severe frostbite. It is normally stored as blocks or pellets in insulated chests. It should be handled with the utmost care and only be done in well-ventilated rooms. Vehicles transporting dry ice or packages containing dry ice should have proper ventilation to prevent carbon dioxide buildup.

Staff handling dry ice must wear insulated gloves, face shields, and safety glasses. They should also have proper training in handling dry ice and dry ice packages. Dry ice must also be kept out of the reach of children at all costs.

Markings on Packages Containing Dry Ice

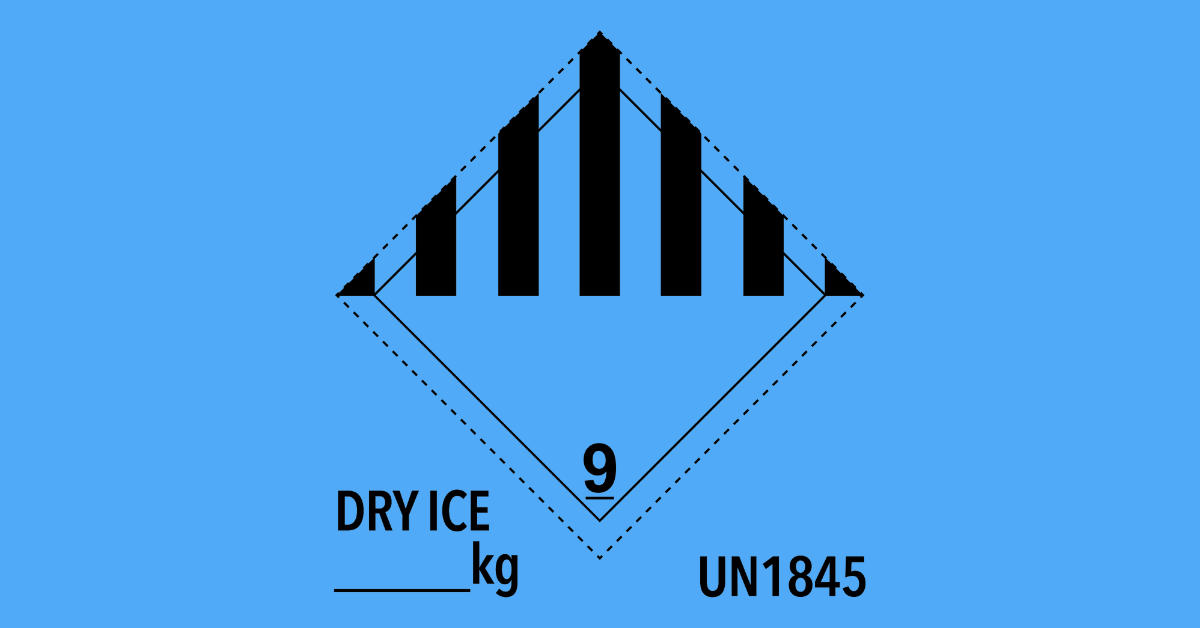

Dry ice is classified as dangerous or hazardous in most countries and has a hazardous substance number of UN 1845. Any dry ice package must carry the Class 9 label (miscellaneous dangerous goods) on it.

Transport operators have to follow various norms and regulations when dry ice is used in the packaging of their cargo – whether it is transported by land, air, or sea.

Cargo packaged using dry ice must be marked (UN 1845) and labelled clearly to indicate that it contains dry ice. The packaging must be strong enough to withstand any damage during transport and handling. The transport bill must show “Dry ice. Class 9. UN1845” and the number of packages containing dry ice, along with the net weight of dry ice used, in kilograms.

How is Dry Ice Made?

The process of making dry ice is simple and, therefore, not very expensive. Carbon dioxide gas is first liquefied, then frozen at a temperature of −78.5° Centigrade (-109° F). It is then compressed into solid form, which is then cut into blocks or made into pellets, as required. Large dry ice blocks are cut using pneumatic saws.

In most cases, the carbon dioxide used in making dry ice is a byproduct of ammonia refinement. Natural gas is burned to separate carbon and hydrogen atoms. While hydrogen is mixed with nitrogen to make ammonia, the leftover carbon is mixed with oxygen to form carbon dioxide.

Carbon dioxide gas is also a byproduct of ethanol production.

Dry ice is usually packed tightly with insulated sheets or paper to slow sublimation.

Food Grade Dry Ice

Sometimes, normal dry ice may not be used to preserve certain pharmaceutical drugs or food items. The carbon dioxide used to make food-grade dry ice is subject to a process called adsorption.

For this, carbon dioxide is passed through a chamber containing a carbon dioxide adsorbent. During adsorption, any other gases are removed, and only clean carbon dioxide is left behind.

This carbon dioxide is then liquefied, frozen, and compressed into large blocks. Later, it is cut into the required sizes. In logistics and transport parlance, this process is called scrubbing.

Packaging of Goods using Dry Ice

Expanded polystyrene foam (EPS) boxes and corrugated cardboard boxes are used to transport temperature-sensitive goods using dry ice for best results. Sometimes, Styrofoam is also used instead of EPS.

The temperature-sensitive goods are placed inside an EPS (or Styrofoam) box, and dry ice is stuffed inside. This box is then secured and placed inside a slightly larger, sturdy, corrugated cardboard box. The space between the two is then filled with more dry ice and closed securely.

The double-layer packaging ensures that the dry ice will last long without sublimation, keeping the goods cold.

Special care should be taken to ensure the boxes are not completely sealed or airtight. The emission of carbon dioxide gas during sublimation can cause pressure buildup inside completely sealed boxes and may cause an explosion.

Generally, with an extremely low temperature of −78.5° C, 10 kilograms of dry ice in an appropriate insulated box will last for about 40 to 50 hours if the packing is not opened in between. But, to a large extent, it would depend on what is packed and how.

Good quality packing materials should be used to ensure the best results.

What are Some of the Other Uses of Dry Ice?

Dry ice has various other uses besides refrigeration. Let’s look at a few of them here.

Dry ice is used to carbonate beverages and make them fizzy and in the manufacture of ice cream. It is also used in decorations that use ice to stop it from melting, in theatres and stages for the fog effect, etc.

When used inside closed containers, dry ice can prevent attack from certain pests, such as insects. It is also used to control pests such as rodents and certain insect baits.

Dry ice also has several industrial uses. The main one is in a process called blast cleaning. In this process, dry ice pellets are shot through a nozzle, using an air compressor to remove various residues, such as paint, glue, oil, mould, etc., from machinery and equipment.

The French inventor Adrein-Jean-Pierre Thilorier is credited with discovering dry ice in 1835. In 1925, it was patented and trademarked in the United States, and it started selling commercially, mainly for refrigeration.

You might also like to read-

- Packing and Packaging in Logistics

- The Ultimate Shipping Container Dimensions Guide

- A Comprehensive Overview of IMDG Code for Shipping Dangerous Goods

- What Are Insulated Shipping Containers?

- What is Stuffing and Destuffing of Shipping Containers?

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

Hari Menon is a Freelance writer with close to 20 years of professional experience in Logistics, Warehousing, Supply chain, and Contracts administration. An avid fitness freak, and bibliophile, he loves travelling too.

Related Articles

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.