Guide to Cold Chain Logistics – Things You Must Know

The growth in global trade over the last few decades has seen several innovations and evolutions in the way of doing business as well as in the equipment and infrastructure that are used for the storage and transport of products.

The evolution of cold chain logistics is a direct result of the growth in global trade and supply chains.

The growing need to transport temperature-sensitive products safely over long distances saw the birth of cold chain logistics.

With better standards of living, especially in the developed nations of the world, people are more aware of the quality and the need to get products and products that are fresh.

Today, cold chain logistics is an important part of any modern successful supply chain solution.

What is Cold Chain Logistics?

The planning and implementation of the safe and secure transporting of any temperature-sensitive product over a long distance, maintaining its correct temperature and humidity requirements, using the right equipment and transport method is called cold chain logistics.

It is also referred to as chill chain logistics. Temperature-sensitive products include certain types of food items, pharmaceutical drugs, biological samples and specimens, beverages, etc.

The term ‘cold chain logistics’ can be a misnomer at times. Depending on the type of product, the temperature requirements to store and transport it will vary.

Not every product has to be kept at very low or sub-zero temperatures. Some of them may need storage and transport at ambient temperatures to preserve their texture and quality. This is true especially during harsh winters in certain countries.

The storage and transport equipment used for such goods have to meet these requirements. Though the term ‘cold chain logistics’ is the one that is commonly used, based on the earlier statement, it may be rightly referred to as ‘temperature-controlled logistics’.

Cold chain logistics impacts every stage of a temperature-sensitive product, from its production, storage at the producing facility, transport to the customer’s warehouse, and storage at the customer’s facility.

Different products have different temperature requirements.

Cold chain logistics provides you with the facility for temperature-controlled warehouses and transportation. The general temperature settings that are followed are:

- Deep frozen meat and seafood -30° C and -18° C (-22° F and -0.4° F)

- Frozen meat and seafood -18° C and 0° C (-0.4° F and 32° F)

- Pharmaceutical drugs etc. 2° C and 8° C (36° F and 46° F)

- Chill fruits, vegetables, dairy products 7° C and 14° C (44.6° F and 57.2° F)

- Ambient fresh produce etc. 14° C and 24° C (57.2° F and 75.2° F)

Modern heavy-duty refrigeration systems help to maintain these temperatures during the storage and transport of goods.

It must be noted here that not all the products listed above get spoilt as soon as the temperature crosses the thresholds shown above.

It is when the temperature fluctuations are steep and frequent (also referred to as temperature excursions) that they get spoilt.

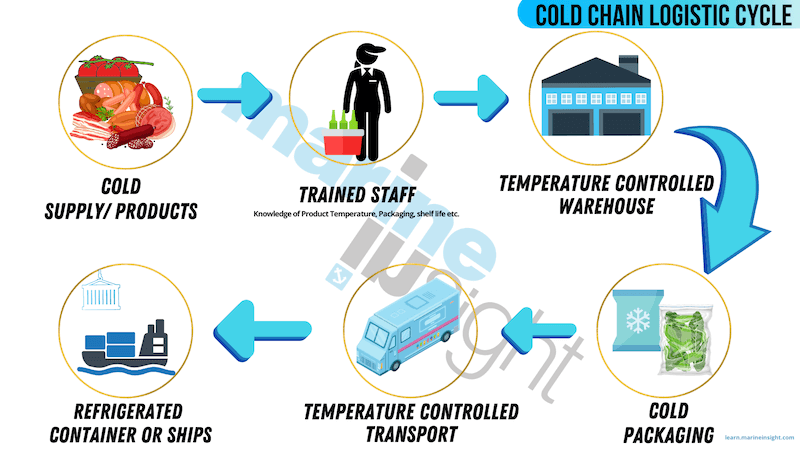

Main Components of Cold Chain Logistics

The main components of efficient cold chain operations are temperature-controlled storage and transport facilities, well-trained staff, and well laid-out procedures for carrying out the activities of the cold chain.

Temperature-Controlled Storage

Goods have to be stored post-production until it is dispatched to a distribution point or a customer. Storage of certain types of goods has to be in temperature-controlled conditions that must be protected from temperature fluctuations and power outages. Power outages can result in deterioration in quality or spoilage of goods.

Most temperature-controlled warehouses have the back up of Uninterruptible Power Supply (UPS) to meet such unforeseen dangers. Infrared thermometers that help to record the temperature from a distance are used in cold storage warehouses.

Where the normal thermometers cannot work due to the extreme cold, wired digital thermometers are used. These are usually found in deep-freeze warehouses or deep-freeze transport.

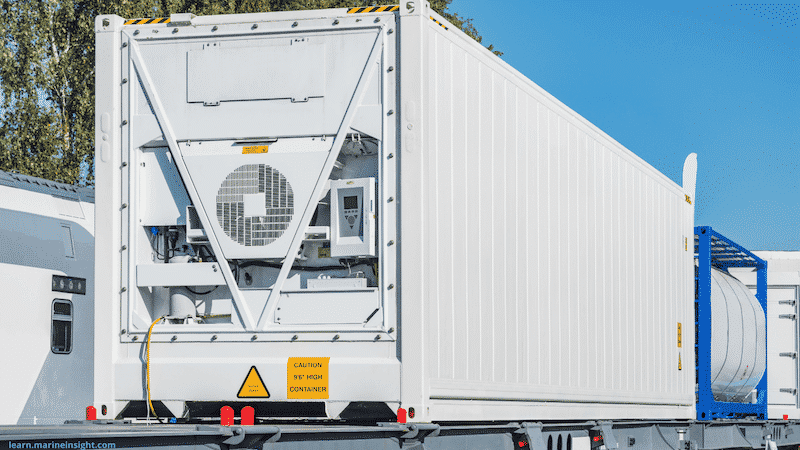

Temperature-Controlled Transport

When temperature-sensitive goods are transported from one point to another, it has to be done in temperature-controlled vehicles that are equipped with refrigeration devices to meet the temperature requirements of the goods.

These are known as refrigerated vehicles or reefer trucks. Such trucks have a separate compartment or container that is temperature-controlled using portable refrigeration units. The refrigeration units run on diesel or battery power.

Reefers usually have electronic temperature monitoring and logging devices that record and report temperatures and other conditions like humidity, etc. inside the vehicle, from the moment the devices are switched on after loading of goods until the goods are offloaded.

These devices known as Electronic Data Logging Monitors (EDLM) are compact and portable devices that record temperature, etc. at intervals. They may even be programmed to send alarms to the operator under certain conditions.

Some of them have alarm systems that go off when the vehicle door is opened or when the temperature goes below or above a set threshold. Some of them are satellite-linked for remote monitoring. These devices help in monitoring the cold chain.

Passive data loggers are also used that simply record the temperature at intervals. This recorded data can then be downloaded and studied at a later point in time.

Another method of maintaining low temperatures inside a transport vehicle with a separate storage compartment is by using dry ice or frozen gel packs.

Dry ice is solid carbon dioxide that is used as a cooling agent. It has a temperature of -78.33° C (-109° F). Frozen gel packs make use of water, a thickening agent, and silica gel.

This method known as the passive system of cooling is usually used for short-distance transport of products that need storage in cool environments.

Selection of the right kind of containers for packing temperature-sensitive products, tracking temperature, humidity, and such conditions during handling and transport, and avoiding temperature fluctuations is the key to managing cold chains effectively.

Qualified Staff

A qualified and well-trained team goes a long way in ensuring the efficacy of the cold chain logistics operations. They must have up-to-date knowledge about cold chain requirements and should undergo refresher training as and when required to keep abreast of equipment upgrades and the latest in cold chain technologies.

Operating Procedures

Cold chain logistics operations should have efficient procedures in place that are easy to understand. The Standard Operating Procedures (SOP) of a cold chain company should negate any risks in its daily operations. A clear understanding of market requirements is also a prerequisite for the smooth functioning of such operations.

Differences Between Cold Chain and Normal Supply Chain

The main difference between the two is that while in cold chain logistics an almost unbroken low temperature (or the desired temperature) trail is maintained during the storage and transportation of goods, in normal supply chains this is not so.

For example, in normal supply chains, products may be left waiting in a common area or yard (marshalling yard) after picking them from their storage locations as they wait for loading to transport vehicles.

Marshalling yards are usually located in ambient areas close to loading bays. Loading bays are also not strictly temperature-controlled. As one can see, the cold chain is broken on these occasions. Modern cold chain logistics make use of chill-corridors for the exclusive transfer of temperature-sensitive goods.

Strip curtains made of polyvinyl chloride (PVC) are used to prevent warm air from entering temperature-controlled warehouse chambers.

Air curtains use strong jets of air that flow vertically from the top of the door frame to its base, effectively shutting away warm or cold air from getting inside the chamber. They act as an insulator or barrier between two areas.

Heated air curtains keep cold air from entering a storage area. Air curtains are particularly useful when people and equipment are moving in and out of an area frequently.

Some warehouses use collapsible temperature-controlled tunnels to move products that are extra-sensitive to temperature fluctuations such as biological samples, pharmaceutical drugs, etc. between storage and transport.

These are also called chill-corridors.

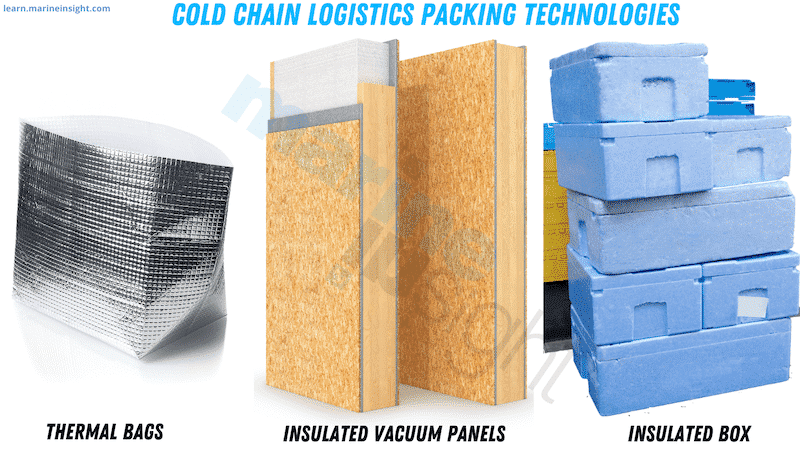

Cold Chain Logistics Packing Technologies

Insulative materials such as thermal blankets, thermal bags, insulated panels with vacuum, etc. are used to transport materials that have special temperature requirements. Let us look at some of these here.

Thermal Blankets and Thermal Bags

Thermal blankets are liners used for maintaining the temperature of cargo within a container. They are like bubble wraps found in the market but made of sturdy insulative materials.

Thermal bags also make use of the same technology that keeps the material inside cool for a long time.

Insulated Vacuum Panels

Insulated vacuum panels have a vacuum between two insulating layers. These are lined on the container walls to protect goods from temperature fluctuations.

Equipment known as Flexitanks is used for the bulk transportation of dairy products, beer, fruit juices, etc. These tanks can carry liquids and viscous fluids between -30° C and +30° C (-22° F and +86° F).

They have the rigid frame and structure of a normal shipping container with a cooling system and a patented bag inside, made of special polymers.

Cold chain warehouses and the equipment used in them have to meet certain structural specifications to withstand extreme temperatures. Failing this, the warehouse and equipment would become prone to structural damages.

Floors and walls can develop cracks under extreme cold. Special epoxy flooring that can withstand such extreme and at times fluctuating conditions can overcome this problem.

The Personal Protective Equipment (PPE) used by employees of a cold chain warehouse has to protect them from the cold as well as provide them with safety. PPE used in cold chain warehouses is more expensive than the ones used in a normal warehouse.

Transportation of Pharmaceutical Drugs and Biological Samples

The multi-billion dollars pharmaceutical industry relies heavily on cold chain logistics for the transport of certain types of medicines.

Medicines and drugs can lose their potency and undergo changes in their composition if they are transported or stored at extreme temperatures or sometimes even at an ambient temperature.

Certain injections such as insulin, antibiotics, etc., certain capsules, creams, and drops need refrigeration during storage and transport.

The common temperature range for the storage and transport of such pharmaceutical products is between 2° C and 8° C (36° F and 46° F). However, each medicine will have a specific storage temperature.

The cold chain begins during the manufacture of medicines and has to be maintained until consumption by the end-user, usually the patient or person being administered the medicine.

During this period, it moves through various warehousing and distribution points, the hospital or pharmacy all of which have to be under a strict cold chain.

The responsibility of a cold chain logistics provider usually ends when the medicine reaches the store of a hospital or a pharmacy.

Biological specimens and samples are normally packed in a primary container that is air-tight and leak-proof. This container is packed inside a secondary container that absorbs any liquid in the event of leakage and withstands any shocks during handling and transport.

Specimens and samples degrade over time unless they are packed and preserved well. Temperatures for preservation and transport of these items range from as low as -40° C to -800° C.

In cold chain logistics that handle biological samples and specimens, every care has to be taken to avoid freeze-thaw cycles that can degrade these items.

Risks Faced by Cold Chain Logistics

Temperature Fluctuations During Storage and Transport

An uninterrupted supply of power is the main requirement for any cold chain logistics operations, be it storage or transport. Frequent power outages and lack of adequate power backup can seriously hamper operations often resulting in damage to the stored materials and consequent losses.

Wastage in Packing and Storage Materials

Cold chain logistics requires special packing materials and storage infrastructure that are expensive. Any wastage, however small, has to be avoided. Wrong planning during the setup or ordering of consumables, however small, can adversely affect costs.

Cold chain technology and infrastructure are naturally more difficult to run and maintain when compared with normal supply chains.

Any structural or equipment breakdown can result in loss of quality or total loss of the stored products. Therefore, proper backup to avoid such situations has to be in place.

Latest innovations for cost-effective cold chain logistics management solutions combine storage as well as communication technologies.

You might also like to read:

- Watch: How Container Shipping Works – The Process Of Transporting Cargo In Containers

- Freight Forwarding Process – Everything You Wanted to Know

- Bill Of Lading in Shipping: Importance, Purpose, And Types

- What is Merchant Haulage?

- Telex Release – Everything You Wanted to Know

- Straddle Carriers – Design, Operation, Advantages And Disadvantages

- What is a Logistics Cycle?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

Hari Menon is a Freelance writer with close to 20 years of professional experience in Logistics, Warehousing, Supply chain, and Contracts administration. An avid fitness freak, and bibliophile, he loves travelling too.

Latest Maritime law Articles You Would Like:

Latest News

- What are Logistics Risks?

- How Port and Terminal Operators Can Control Emissions?

- Minimum Quantity Commitment (MQC) and Liquidated Damages in Container Shipping: Concept and Relevance

- MARPOL (The International Convention for Prevention of Marine Pollution For Ships): The Ultimate Guide

- The Ultimate Shipping Container Dimensions Guide

- A Comprehensive Overview of IMDG Code for Shipping Dangerous Goods

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.