8 Common Mistakes While Operating Deck Machinery Systems

Working on ship’s deck involves carrying out routine procedures such as painting and chipping, operating deck machinery, or handling cargo. Most of these jobs involve handling one or more types of deck tools and equipment while performing them.

Though a variety of mistakes can occur while operating deck machinery systems, there are a few errors which are very common on all types of ships. Deck officers must take extra precautions with eight of the most common mistakes involved with deck machinery operations that are mentioned below:

1. Bow Thruster: The deck officers operating the bow thruster joy-stick must never increase the pitch from minimum to maximum in one go. It can lead to sudden increase in current and damage the motor as the BT system involves using high voltage and current. Also, maximum given pitch should never exceed 90% and operation at higher pitch must not be continued for long duration of time.

2. Mooring Winch: When ship is berthed in the jetty, the berthing/securing operation of the ship is performed by using mooring winches. Avoid using the brakes of the winches in place of using reduction gear to reduce or control the speed or else it will damage the brake lining of the drum.

3. Anchor Winch: Always use chain stopper when no operation is being performed and while greasing the ship’s anchor parts. Never grease friction washer or brake lining as this will lead to slippage of the anchor chain while stopping.

4. Deck Crane: All cranes comes with maximum safe working load capacity which is stenciled on the crane body for ready reference. Still it’s observed that many deck crew members lift loads without even checking the load of the lifting structure/body/ item.

5. Ballast system: Never start the ballast pump from the cargo control room without checking the system valves and pump conditions from the local position in the engine room.

6. Hydro blaster: For the safety of ship’s personnel, a safety switch is provided on the hydro blaster. This “Dead man’s switch/trigger” must never be taped, tied, or otherwise altered so that the equipment stays in the “ON” position. Also, if the high pressure pipe is not handled properly, If the lance is dropped it will whip about wildly, causing serious injuries.

7. Welding/ Gas cutting : The deck maintenance commonly involves “hot work” which requires using welding machinery. Do check the insulation of welding cable and condition of the gas cables before using them. Check the surrounding of the hot work area (near fuel tank vent, oil tank sounding pipe etc.) before starting the job. Also ensure that the gas cutting piping system is equipped with flash back arrester in the line before the gas bottles.

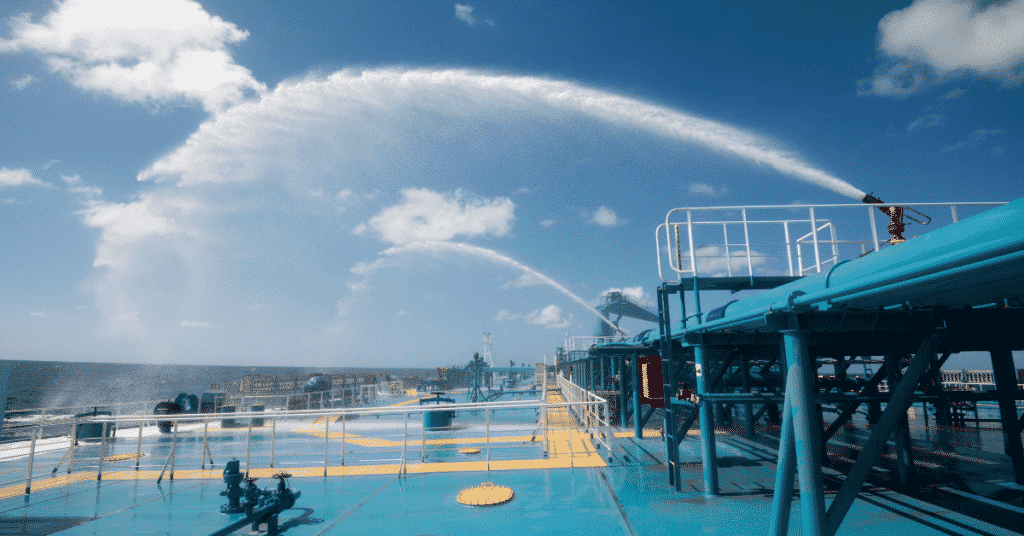

8. Fire System: The fire system of the ship is supplied with high capacity fire pumps which provide water to the hydrants present in deck and engine room. These pumps are used for emergency situations and thus should not be isolated at any time. However, don’t forget to isolate the fire pump and the system when carrying out any kind of maintenance in the line. Also, after maintenance don’t forget to close the drain of the fire line.

Do you know about any other common mistakes related to deck machinery operations that are seen on board ships? Let us know in the comments below.

Further Readings:

1. The Ultimate Guide to Cargo Operation Equipment for Tankers and The Ultimate Guide to Cargo Operations for Tankers offer procedures and explanations for a variety of cargo operations and deck machinery systems.

2. You might also like to read our eBook – The Ultimate Guide to Deck Machinery Procedures and Operations which explains procedures for operating all deck machinery systems, along with other important guidelines.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Latest Ship Safety Articles You Would Like:

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Master Mariner for Panamax or handy max vessel.

These eight tips are very important to remember all the time and it is necessary for the workers on ships to pay much attention to them in order to avoid the mistakes. Keep safe operations value most. I got much useful information from your article.