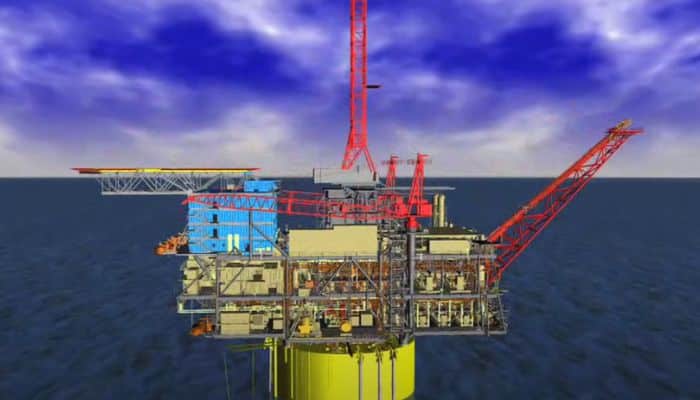

10 Major Oil Rigs In The Gulf Of Mexico

The Gulf of Mexico is close to the southern coast of the U.S and is often called the United States ‘Third Coast’. The straits of Florida connect it to the Atlantic Ocean, and the Yucatan Channel links it with the Caribbean Sea.

The Gulf of Mexico spans 1,680,000 sq km with a maximum depth of 7,020 m. It is popular for fishing, shipping, recreation and tourism.

However, it is known worldwide for being the western hemisphere’s 2nd most productive oil basin, dotted with hundreds of oil and natural gas fields, thanks to Mississippi and other rivers, which deposited rich organic mud and sediment into the Gulf for millions of years.

The Gulf of Mexico reserves are estimated to contain 3.44 billion barrels of oil and 5.7 trillion cubic feet of natural gas that can be procured from the 459 active oil and gas fields in the region.

The Gulf of Mexico offshore oil production is 15% of the total crude oil production of the United States. Also, offshore natural gas production in the Gulf of Mexico is 5% of the total dry production in the country.

There are hundreds of active oil rigs and platforms in the Gulf of Mexico, with the major ones operated by key players, including Chevron Corporation, Shell PLC, ExxonMobil Corp, and BP PLC, among others.

But when did oil platforms appear in the Gulf of Mexico region?

Oil platforms in the Gulf of Mexico began appearing in the 1940s and became more elaborate, complex, advanced and multi-purpose structures with the passage of time.

The initial oil rigs were small and were used to extract oil from the nearshore wells. In the 1970s, bigger platforms were being constructed in deeper waters.

Today, there are thousands of oil platforms in the Gulf of Mexico, which play a crucial role in the availability of oil and gas across the globe.

With technological advancements, oil companies have taken drilling and production farther from the coast into deep waters.

In the Gulf of Mexico, oil rigs go beyond the edge of the continental shelf, 100 miles offshore, to around 350 miles from the Gulf shores.

Let’s explore the 10 Major Oil Rigs in the Gulf of Mexico.

The Petronius Oil Platform

Petronius is one of the biggest oil platforms in the Gulf of Mexico, operated by Chevron, 210 km southeast of New Orleans, US. It is also one of the tallest free-standing structures in the world.

This compliant tower oil rig was built from 1997-2000. It weighs around 47,399 tonnes and operates at a depth of 1754 feet.

Its tower design enables the rig to sway with tidal currents rather than resisting movement. It is 2001 feet high with a multi-deck topside harbouring important equipment, living spaces for the workers, pipelines, operations room and the drilling rig.

The Petronius platform extracts 60,000 barrels of oil and 3,000,000 m3 of natural gas daily.

This structure was constructed to exploit the Petronius field, found in 1995, and named after the famous Roman writer, Petronius.

Perdido Spar Platform

Perdido is the world’s deepest spar and the 2nd deepest oil and gas production platform after Shell’s Stones Development. It is operated by Shell and has remained operational since 2010.

It contains a spar platform moored in 2450 m deep waters, serving as a hub of production for the Great White, Silvertip and Tobago deepwater fields.

Perdido can process 100,000 barrels of crude oil and 200 million cubic feet of gas daily.

The host platform has a 170 m long cylindrical spar hull weighing 22,000 tonnes, designed to face the most powerful storms.

This spar hull was built in Pori, Finland, and transported to the Gulf of Mexico via the Baltic Sea in 2008.

Perdido has 3 topsides, and its decks are as big as 2 football fields. It houses oil and gas production units, living quarters for 170 people and a drilling rig.

Around 12,000 people were involved in the project at the peak of its construction, and equipment for the same was brought in from around the world.

The biggest challenge was that all the equipment had to be light enough to be shipped using floating cranes.

Olympus TLP

The Olympus, a tension leg platform or TLP, is situated one mile or 1.6 km from the Mars Platform. This Shell-owned structure is the biggest floating deepwater platform in the Gulf of Mexico for extracting oil from the Mars oilfield.

This platform was installed to extend the production life of the deepwater oilfield to 2050 and more. The platform has processing facilities enabling the production from nearby Boreas & South Deimos fields as well.

The platform’s hull was completed in 2012 and shipped from the construction yard in South Korea to Ingleside, Texas, in 2013 using a semi-submersible, heavy-lift vessel called Blue Marlin.

The project involved 25,000 people at the peak of construction, and the first oil was extracted in January 2014.

Olympus platform can process around 100,000 barrels of oil per day. It has 24 well slots, a drilling rig and a helipad.

It is 406 ft high and weighs over 120,000 tonnes with a combined deck area of 342,000 ft2. There are four-storey living quarters for 192 people, featuring pantries, a control room, a medical facility and fitness spaces.

Atlantis Platform

The deepest-moored floating oil and gas structure at the time of its installation, the Atlantis, is 305 km south of New Orleans.

It features a semi-submersible design, and the production platform is supported by a distinct mobile offshore drilling unit.

Lying in 2150 m of water, the oil field covers 5 blocks with water depths ranging from 4400 to 7100 ft.

Though scheduled to start operations in 2006, progress was delayed due to hurricanes and other factors. However, the first oil was produced by the platform in 2007.

Initially, the capacity was around 10,000 barrels of oil per day, but it peaked in 2008, producing 200,000 barrels of oil and 180 million cubic feet of gas daily.

In 2019, BP announced its plans to expand the Atlantic at a cost of $1.3 billion.

This development came after an additional 400 million barrels of oil was found in the field using the latest seismic imaging technologies. After the completion of the expansion phase, the oil production capacity of the platform will increase by 38,000 barrels per day.

Shenzi Platform

The Shenzi Platform lies 195 km off the Louisiana coast in the Green Canyon protraction region in the Gulf of Mexico.

This stand-alone tension leg platform stands in 1310 m deep waters, producing oil and gas with a daily production capacity of 100,000 barrels and 50 million cubic feet.

The Shenzi platform’s topsides were fabricated by Kiewit Offshore, and its hull by Samsung. The topsides are spread over 3 decks, supported by the 4-column hull.

The oilfield was discovered in 2002, and the first oil and natural gas from the facility were obtained in 2009. Currently, Shenzi has 17 wells, and two are under development.

Woodside has 72% interest in the Shenzi field as its operator, while the rest 28% lies with Repsol. Woodside Petroleum Ltd acquired the platform as part of its 2021 agreement with BHP Group to combine their oil and gas portfolios.

Magnolia ETLP

Magnolia is an extended tension leg platform (ETLP) and offshore oil drilling facility in the Gulf of Mexico. Its height from the seabed to the top is 4698 ft. Hence, it is considered to be the world’s tallest structure by many.

It was the world’s deepest ETLP, overtaking the Marco Polo by 120 m; however, in 2018, the Big Foot ETLP, reaching 5180 ft, took over Magnolia.

The Magnolia Field lies 290 km south of Cameron, Louisiana, in the Gulf of Mexico. The main function of the platform is to produce oil from 5 wells. It has a capacity for 50,00 barrels of oil and 150 million cubic feet of natural gas; however, it produces 5,000 barrels daily as of now.

Underwater pipelines transport this oil to the Shell Enchilada platform, a processing and transportation hub.

Magnolia is a floating platform and is held down by steel tethers linked to the seafloor. Its hull comprises 4 cylindrical columns connected below the waterline using a rectangular pontoon frame.

Baldpate Oil Platform

Situated in the Gulf of Mexico, 110 miles off the coast of Louisiana, in the Garden Banks area, the Baldpate was the first-ever free-standing offshore compliant tower.

Baldpate Platform is the 2nd tallest structure constructed in water after the Petronius Oil Platform.

This 579.7 m structure was designed and constructed by Hudson Engineering, now J Ray McDermott Engineering in Texas and was installed in its place by Heerema Marine Contractors.

Owned and operated by Hess Corporation, the compliant towers of the platform are more flexible than the fixed truss towers. Baldpate was designed in a way so it could move up to ten feet laterally in rough seas and storms.

The platform was constructed in multiple sections that were assembled later when it reached its final destination.

The structure’s main components, including the compliant tower section jacket, weighing 28,900 tonnes, were made by Aker Gulf Marine.

The structure’s main legs have a 12 ft diameter, and the corner of each side is supported by steel piles reaching a 430 ft depth.

Mad Dog Spar Platform

The Mad Dog Oil Field lies at the Green Canyon Blocks, Western Atwater Foldbelt in the Gulf of Mexico, 310 km south of New Orleans, in 1500 m to 2100 m deep waters. It was discovered in 1998 and started operations in 2005. The oil field is owned by BP, Chevron and BHP.

Per estimates, the field has reserves ranging from 200 to 450 million barrels of oil with a daily production capacity of approximately 100,000 barrels and 60 million cubic feet of natural gas.

The Mad Dog Spar Platform was built in Finland. Its hull is 169 m long with a diameter of 39 m. It contains 13 production slots and living quarters for 126 people. Oil from the platform is taken to Ship Shoal 332B through the Caesar Pipeline, while natural gas is shipped through the Cleopatra Pipeline.

In 2008, Mad Dog suffered damage in Hurricane Ike. Its drilling derrick toppled and lay on the seafloor. Another drilling package was constructed and installed on the spar in 2012.

Thunder Horse Platform

The Thunder Horse Oil field is located 240km from New Orleans, Louisiana, in the Gulf of Mexico. It has massive reserves with new oil discoveries made recently, in 2019. BP plc and ExxonMobil are involved in its development.

Thunder Horse is the biggest offshore production facility in the Gulf of Mexico region, with a handling capacity of 250,000 barrels of oil and 200 million cubic feet of gas per day.

This structure is also the largest moored semi-submersible oil platform in the world, situated in 1920 m of water. Its hull section was constructed by DSME in South Korea and delivered to the installation site in 2004.

It was evacuated in 2005 due to Hurricane Dennis. The platform was listing after the hurricane. However, there was no damage or leak from the hull. Instead, water gushed in through a pipe, which led to the structure tipping in the waters. It was righted a few days after the hurricane passed after the required repairs were completed.

Mars TLP Platform

The Mars Tension Leg Platform, involved in offshore drilling and oil & gas production, operates in the Mississippi Canyon Blocks in the Gulf of Mexico, producing its first oil in 1996.

It is owned by Shell Oil Company and BP, with the former being the majority share owner and operator of the structure.

It lies in 896 m of water and is made to produce approximately 220,000 barrels of oil and 220 million cubic feet of gas daily.

Shell began developing the Mars Platform in 1993, using a self-designed and engineered TLP, which was installed 3 years later at 2490 ft water depth, becoming the deepest such structure at that time when measured from the base to the top.

It was damaged when the Gulf of Mexico was hit by Hurricane Katrina in 2005; however, after it underwent considerable repairs, it began producing a little above the pre-hurricane levels in 2006.

No significant injuries were recorded in over a million man-hours taken in the repair work at the platform, a key milestone of the Recovery Project.

You might also like to read-

- Life On An Oil Rig – Do You Know What It Takes?

- Types Of Mobile Offshore Drilling Units (MODU)

- What are Anchor Handling Tug Supply Vessels (AHTS)?

- A Guide To Types of Ships

- Main Reasons that Lead to Oil Rig Accidents

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

Zahra is an alumna of Miranda House, University of Delhi. She is an avid writer, possessing immaculate research and editing skills. Author of several academic papers, she has also worked as a freelance writer, producing many technical, creative and marketing pieces. A true aesthete at heart, she loves books a little more than anything else.

Latest Maritime Knowledge Articles You Would Like:

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.