How Marine Air Charging System For Engines Has Changed Over Time

Diesel engine for propelling ships came in to picture in the early 19th century. They not only helped to reduce the heat losses (steam engines) from engines but also to increase the speed and fuel efficiency of the ships.

For efficiently burning diesel fuel in the engines, it is imperative that sufficient air is supplied at every cycle inside the cylinders. To achieve this, a variety of methods were adopted for supplying fresh air to burn the fuel and to produce the required power within all cylinders of the engine.

Before turbocharging came, the process of supercharging process was used. A mechanical arrangement within the engine was used to supply extra air to the combustion chamber of the engines. In this article, we will discuss different methods and arrangements used to supply fresh charge air:

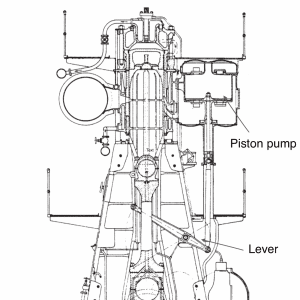

1.Mechanically driven side mounted air pumps: In early 1900s, engineers made it possible to supply additional air using mechanically driven side mounted air pumps. These pumps had a belt attached to the crankshaft of the engine which supplies the fresh air taken from the atmosphere

2. Side mounted pumps for each unit: Then came the side mounted pumps for each unit, which is driven by levers attached to the crosshead of the engine piston rod assembly. This arrangement was quiet popular to supply scavenge air in to the combustion chamber

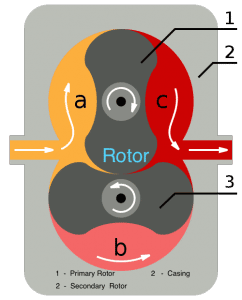

3. Roots type blower pump: It was followed by use of Attached roots type blower pump having two lobe type rotors supplying fresh air to the engine.

4. Electric motor driven blower: Electric motor driven blower for engines, which are used till now to provide initial charging air during the start of the engine, were then used.

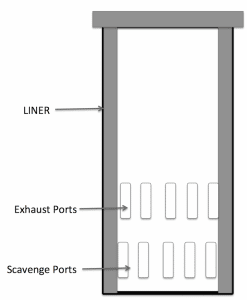

5. Scavenge ports: Scavenge ports provided in the cylinder liners are widely used in old marine engines to charge the combustion chamber with fresh air when piston is in its downward motion.

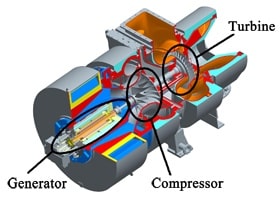

6. Turbocharger: Turbocharger, the most efficient machinery to provide charge air for combustion purpose and which is now used in all marine engines (2stroke and 4 stroke), was prominent in 1950s and is still used with a supercharging system in 2 stroke engines (engine blower)

7.Two-stroke turbocharger: Two-stroke engine turbocharging is achieved by two distinct methods, respectively termed as the ‘constant pressure’ and ‘pulse’ systems. It is the constant pressure system that is now used by all low speed two- stroke engines.

8. Scavenge air coolers: With the increase in demand of power for marine engine, it became important to control the temperature of the combustion chamber and hence scavenge air coolers were placed in between the turbocharger and engine cylinder.

9.Variable geometry turbine: Variable geometry turbine (VTA) is the new age technology which can work at low engine load and eliminate the requirement of additional engine blower from the system. The VTA provided with movable vanes are replaced with conventional fixed vanes, which can change angles to control the exhaust flow on the turbine blades. This helps the engine control to balance the volume of air with the fuel along the entire engine load range.

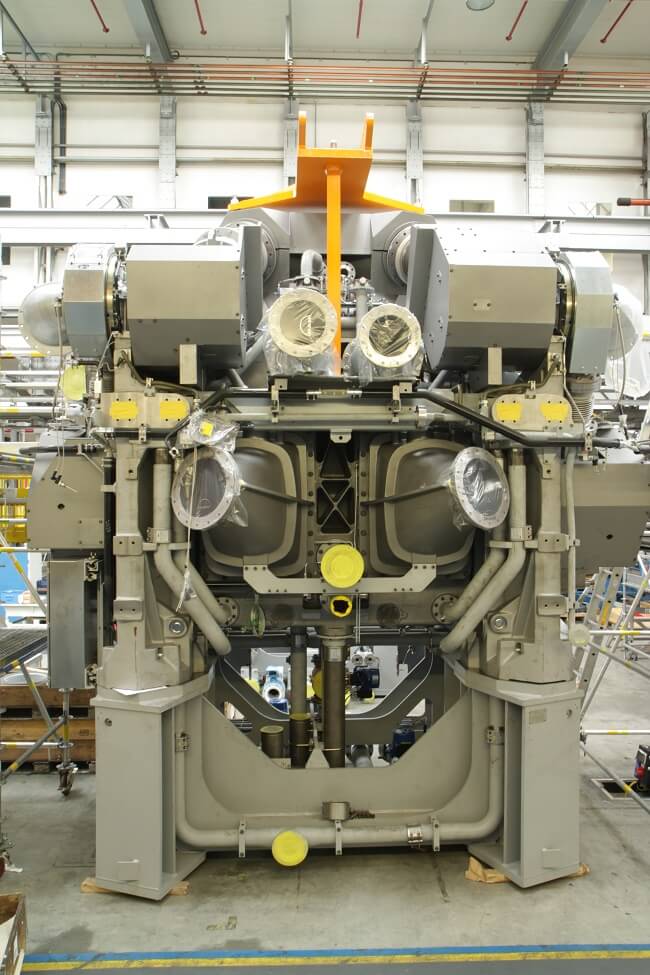

10. Dual or Two stage turbocharger: In today’s time, the ship owners have to ensure that the pollution produced by ship’s engine is under control. One such turbocharging system used for this purpose is the Dual or Two stage turbocharger, which reduces the harmful NOx emissions from the engine by 80%. There are two different sizes of turbo chargers arranged in series which provides higher pressure ration than that provided by the best available single stage Turbo charger.

The turbine from the smaller turbo charger unit is positioned upstream of the turbine of the larger unit from the engine exhaust flow system. For air side, bigger turbocharger compressor is fed into the smaller unit’s compressor. Inter cooling system is provided in between the two stages which reduce the temperature and the volume of the outlet air. This allows 2nd unit to be smaller making the whole system compact.

11. Hybrid turbocharger: Hybrid turbocharger is developed by Mitsubishi heavy industries and it differs from conventional turbochargers in terms of both waste recovery and fuel saving. Exhaust gas energy is recovered to turn the compressor, which supplies scavenge air to the main engine and also generates electricity through an alternator attachment incorporated in the turbocharger known as MET hybrid turbocharger

The air charging in modern marine engine is now done by Constant pressure turbocharger or by VTA turbocharger. With more sophisticated system being implemented on the engine, we may see a different breed of these high speed, fuel saving machinery in near future.

Over to you..

Do you any other air charging technology used in marine engines? Let’s know in the comments below.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Thanks for give us to detail of marine works I m a hose technician if u have a requirement for the technician contact me and my experience of 12 year my age 34 thanks

Good article. Please be noted that correct spelling ” The Roots ” supercharger, not Root. It’s named after it’s inventors Roots Brothers.

@Vitalii: Thank you for pointing out an important error. Rectified.