7 Underrated Marine Technologies That Can Give Promising Results

Just like in any other industry, research and development consume a majority of investments in the maritime industry as well. With introduction of stricter environmental norms and regulations in the industry, shipping companies are taking the best of help from the latest technological advancements to reduce their carbon footprints and increase the ship’s overall efficiency.

In the last decade, the maritime industry has seen a myriad of technological innovations aimed at reducing carbon emissions from ships, improving fuel efficiency, and making machinery systems more reliable. Many of these technologies either failed to get implemented or faced delays in the development process.

But there are a few great innovations that have proved their mettle with the constantly changing norms of the maritime industry. The only point is that they are still not being used as extensively on ships as they should because of a few drawbacks.

Mentioned below are seven such exceptional technologies that would become an integral part of maritime industry in future if implemented and utilized in the right manner.

1. Hybrid Turbocharger for Marine Engines

Ever thought of drawing energy from a marine system which is already an energy recovery system? Well, the hybrid turbochargers for marine engines does exactly that. A system which does not use fuel directly and still generates power is something that will be admired by all, especially when the fuel costs are ever rising. However, this great technology is not being extensively used as it is expensive and complicated as well. If used in the right way, they can produce some great results.

Know more about hybrid turbocharger here.

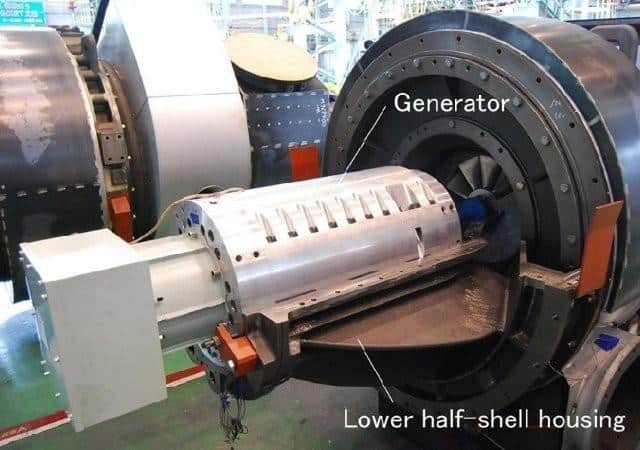

2. The “Cutting Edge” Emergency Propulsion System

We have often heard of situations wherein the ship’s main engine has shut down in mid-sea, causing the ship to go out of control. In case of grounding or any other kind of accident, shipping companies have to spend thousands of dollars in towing the ship to the nearest port. An innovative emergency propulsion system works great in such situations without the need of tugs. In this system, the propeller shaft is attached to a motor during emergency to propel the ship to the nearest port.

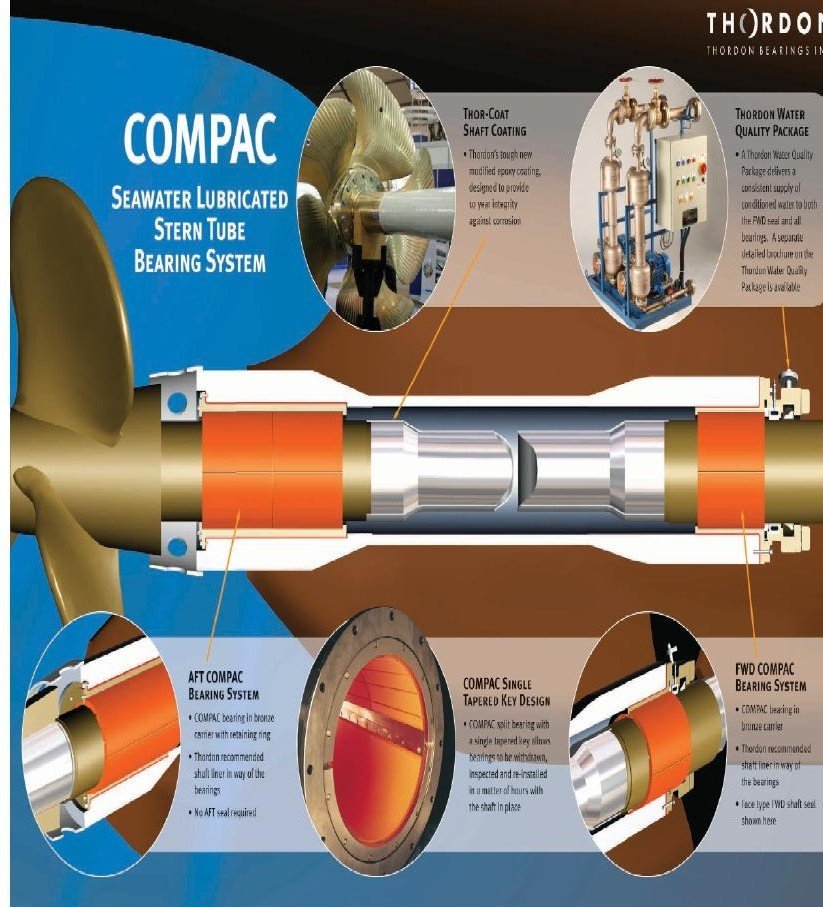

3. COMPAC Stern Tube Bearing System

There are two main things shipping companies are afraid of – Oil pollution from their ships and high cost of maintenance. It is a known fact in the industry that the maintenance of ship’s stern tube system is an extremely costly task which every ship has to undergo in dry docks (once every 3 years). Moreover, there are high chances of oil leakage from the stern tube whenever the ship’s draught is less.

The revolutionary COMPAC Stern Tube Bearing System gives a maintenance-free run of 10 years and uses water for lubrication, saving cost of lube oil and eliminating any chances of oil pollution.

Know more about this stern tube bearing system here.

4. Lambda Control

Just like oil pollution norms, there are air emission norms which every ship has to comply with. However, it is not always possible to control the amount of smoke emitted from the ships especially from generators during start-up and when there is load variations. Port authorities often come on board ships to complain about thick smoke coming from the funnel. Lambda control supplies additional air during start up period which reduces the black smoke by minimizing improper combustion.

However, since it is an additional system and not a requirement, very few ship owners actually think of installing this control system. The lambda control is a smart solution to reduce such kind of problems, including the maintenance cost of the machine.

Know more about Lambda Control here.

5. Reverse Osmosis: Modern Alternative for Shipboard Water Production

Reverse Osmosis is a famous system for land based operations. The system has its own advantage over conventional water production on ships, especially for those with high water demands (cruise, platforms etc.). Moreover, it also produces purer form of fresh water than that produced by conventional methods used on ships. Drawbacks such as high installation costs of the plant and inability to utilize the waste heat energy (from jacket water) unlike that in conventional heat-exchanger type fresh water generators (FWG), makes this system not so popular in the maritime sector.

Know more about reverse osmosis process here.

6. S- Separators for Fuel Oil

Known to be one of the most trusted and famous brands for supplying separators to the shipping industry, Alfa Laval claims that their S -separator is highly reliable and has lowest life cycle cost. With disc modifications and added enhancements to the disc stack among other improvements, this allows up to 20% more flow with retained separation performance. This is a highly advanced separator for ships and should be used more often.

Know more about Alfa Level S Separator here.

7. Variable Geometry Turbocharger (VGT)

Not so underrated, but still not very visible in the industry, VGT is a revolutionary technology, patent of MAN diesel and turb,o which allows marine engines to improve fuel combustion and efficiency even at slower speeds. In the age of slow steaming this technology is a boon for marine engineers on board ships and also for the shipping companies. The VGT also helps in reducing the NOx emission from the ships and there is no requirement of an auxiliary blower in the engine. Morever, VGT is a MAN technology and the other major marine engine manufacturers use conventional turbochargers that don’t have VGT.

Know more about Variable Geometry Turbocharger here.

Do you know about any other marine technologies that aren’t being used as much as they should be?

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

actually alot of things u can save in tradional way..but becoz of neglect,no body bother about it..such as servicing the steam trap,increase the condensate temp (i’ve done this to all steam trap and condensate,and the boiler load amazingly reduce to about 1-2t/h),maximize the aux engine load(as the lower load will accumulate the carbon built up on turbine side)…

A heard some time ago about, using the magnetic system to propel ship and they tested in japan.

i want doing work in marrine engineering at any proffesional site. now i am doing study in diploma in mechanical engineering

Dear Shubham,

Please reefer following post regarding your query-https://goo.gl/ma9pYB

Hello, I am from Kenya, currently doing a Bachelor’s degree in marine engineering, I would like to get more ideas on the new inventions that can be made in marine engineering sector to supliment on my project. Thanks