Understanding Structure Design of a Submarine

This is the fourth part of the series of submarine design. Please read the first three here – Introduction to submarine design, Understanding submarine design and Unique tanks on a submarine

Approximately 40% of the focus and priority in the entire submarine design process is given to its structural design. The full process of designing its structure also takes up majority of the time, as it is not only related to strength factors, but also to a nexus of functional aspects that are interrelated to it.

Structural design always begins with the process of identifying the loads that the structure would be subjected to. The loads on a submarine during its mission can be classified into the following:

1. Loading Due to Diving Pressure:

Depth is one of the most important and deciding structural design criteria. The pressure hull is the primary structural element of the submarine, and is designed to be able to withstand the external hydrostatic pressure. It is designed for a particular collapse depth, at which complete failure is expected within a very narrow range. The collapse depth is actually calculated by multiplying the maximum operable depth (MOD) or service depth with a factor of safety. The hydrostatic pressure at this depth is considered as the design pressure for all the pressure hull calculations.

In usual design, safety factors of 1.5 are used, and submarines designed to such limits should not go below the service depth. Whereas, in designs allowing higher safety factors like 2.5, they can dive deeper than the service depth, but only in emergency conditions.

2. Shock Loads:

A submarine is designed to withstand the loads generated by underwater detonations (for example, mine explosions, pressures generated by bursting of large underwater gas bubbles).

The physics of underwater explosions is a very interesting subject, as in, it is remarkably unique when compared to an explosion in air. To understand it, watch the video below, and notice how the explosion ball is created and how it contracts and explodes again, to release a cloud of gas bubbles.

At the instant of explosion, a shockwave is created, which applies radial outward pressure on the water around the point of explosion. This ball of explosion expands to the point where the internal pressure on the inner wall of the ball becomes equal to the external hydrostatic pressure due to the water around it. Now that the ball has expanded, the pressure at its centre is lower than the external pressure. This is what causes it to contract and implode. This implosion generates a cloud of gas bubbles which expands radially. The same process of contraction, implosion and expansion recurs in series till the energy of the explosion is completely dissipated. The diameter and magnitude of each recurrent explosion is less than the previous.

The study thus helps us conclude, that when a submarine is subjected to an explosion, it should be able to withstand not one, but a series of shockwaves. It has also been observed during tests, that due to each contraction of the explosion cloud, the submarine has a tendency to be sucked towards the centre of the explosion cloud. The worst case scenario is an explosion under a submarine, as a result of which the suction is downwards, and it if caused at maximum service depth, can result in the submarine being sucked into larger depths, causing additional risk to the structure due to hydrostatic pressure.

Apart from the direct shock load imparted from the explosion, each shockwave from a single underwater explosion causes a wave of vibration to propagate along the pressure hull. Vibratory loads not only reduce the fatigue life, but can cause resonance resulting in major structural failure.

3. Other Loads:

Like a surface ship, a submarine in surfaced condition is subjected to longitudinal bending loads, transverse shear forces on transverse structures, and torsional loads caused due to wave action.

Local loads like longitudinal and torsional vibrations are caused by action of engine. The structure is to be so designed that the level of vibrations are well within the limits.

Strength of the Pressure Hull:

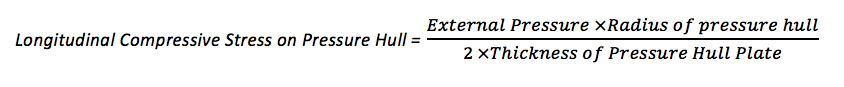

The cylindrical pressure hull in dived condition is subjected to longitudinal compressive stress. This longitudinal stress is of half the magnitude of the hoop stress or the circumferential stress.

The following expression for the longitudinal stress on the pressure hull is used for obtaining the required thickness of the hull and the scantlings of the stiffeners required to prevent failure of the pressure hull by buckling.

The longitudinal stress therefore is a function of the external pressure, the radius of the pressure resistant hull, and the thickness of the hull plate. Now, what role does a submarine designer play with this equation? The radius of the pressure hull is an input from the client, as in, the radius of the submarine is specified along with a range, and this would mean that the pressure hull radius is a fixed entity for the entire structural design.

The hydrostatic pressure at the collapse depth is considered as the external pressure in this calculation. Since the collapse depth is also specified in the contract, it remains fixed. The remaining variable in thickness of pressure hull. Now, the maximum longitudinal compressive stress on the pressure hull is determined by the yield strength of the material used. What a designer calculates for a particular material, is the minimum thickness that is required to keep the stress within limits.

The following observations can be made from the above relation:

- For a fixed MOD, a submarine with larger diameter requires thicker pressure hull plate than a submarine with lesser diameter.

- The minimum thickness of the pressure hull required for a submarine can be reduced by using material with higher yield strength. A lesser thickness would be advantageous in reducing the weight, but comes at a cost of higher price.

The pressure hull shell absorbs all the forces in the longitudinal direction without the requirement of transverse ring stiffeners. However, the shell is stiffened by ring stiffeners that can absorb the circumferential stresses originated due to buckling loads. The ring stiffeners (usually T profiles) are welded to the pressure hull shell, and the entire system acts as one unit.

The pressure hull can fail in three modes, and the probability of occurrence of each mode depends on the arrangement of the stiffeners, as discussed below:

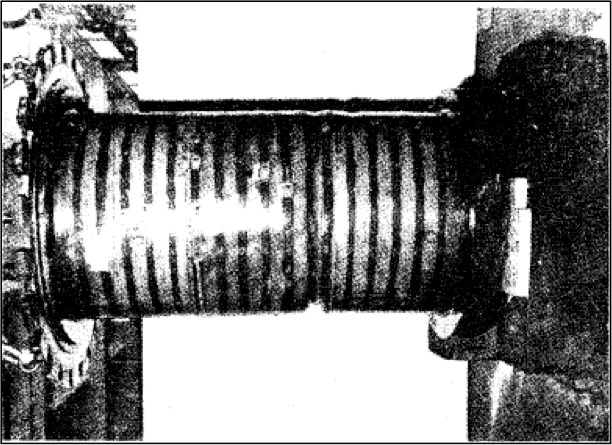

Failure Mode 1: The first mode of failure occurs when the ring stiffeners have high scantling and are placed very close to each other. This results in yielding of the shell plate between two consecutive frames. The yielding occurs over the circumference of the shell between two frames, and hence, is also called symmetrical buckling, as shown in the image below.

Failure Mode 2: This mode of failure happens when the scantling of the frames are too low, and they are placed too distant from each other, that is, in case of larger frame spacing. The shell plate, in this case buckles in the form of a wave throughout the circumference between two consecutive frames. One buckle will be directed inward, while the next one will be directed outward, as shown in the schematic figure below.

Note that the number of waves created in the above case is five, hence it is called a five-lobe buckling. The number of lobes created can vary from two to five, depending on the spacing between the stiffeners and the stress. The following figure shows a real image of shell buckling between frames.

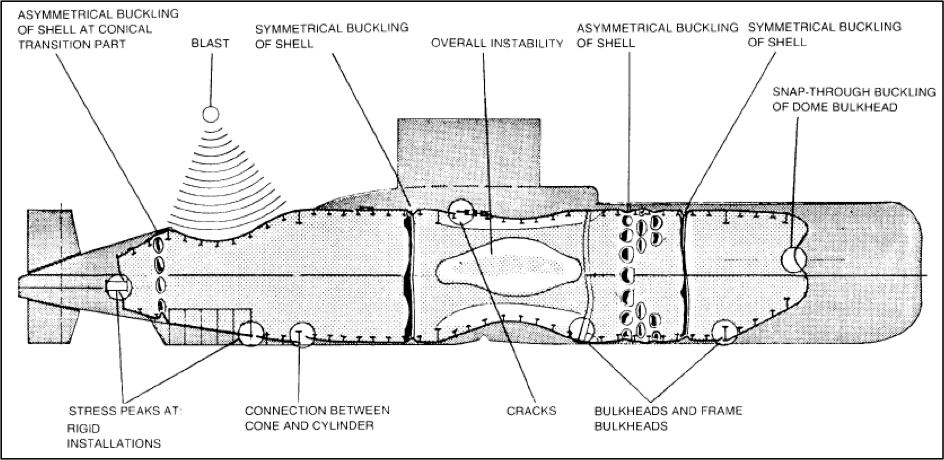

Failure Mode 3: The first and second modes of failure were local failures, and any such occurrence would not post immediate threat to the integrity of the complete structure of the pressure hull. But failure in mode three involves buckling of the pressure hull over its entire length, and this causes the transverse rings to bend out of axis, as shown in the image below. The effect would extend to the length of the pressure hull between two heavy transverse structures like bulkheads or heavy web frames. This is also called total collapse of pressure hull. This is caused due to inadequate strength of the material, or when the submarine dives to depths more than collapse depth.

Other than the above three modes of failure, some other failure modes for a pressure hull are as discussed below:

- General instability of the pressure hull shell, circular frames, bulkheads and decks caused by improper welding or improper scantling calculations may lead to local failures or failures extending to a series of frames.

- Snap-through buckling may occur at the forward elliptical bulkhead (dome) or the aft conical bulkhead as these shapes are subjected to varying compressive loads.

- Low cycle stresses on the pressure hull structure may lead to development of cracks followed by crack propagation.

- Failures due to stress concentration at regions of discontinuity in shape, for example: the joint between the cylindrical section of the pressure hull with the aft conical and forward elliptical ends is subject to high stresses.

The following figure summarises the nature of failures that a pressure hull is prone to, and their effects on the geometry of the structure.

Quick Fact: The pressure hull of submarines can be stiffened either internally or externally. But external stiffening is ore preferable due to the following reasons:

- It has been observed that external stiffeners of the same scantling as that of internal stiffeners, provide 5 percent more strength than the latter.

- Since external stiffening occupies the space between the pressure hull and outer hull, a lot of usable space can be obtained within the pressure hull.

But some designs, especially where the pressure hull is itself the outer hull for most part of the submarine’s length, internal stiffening remains the only option.

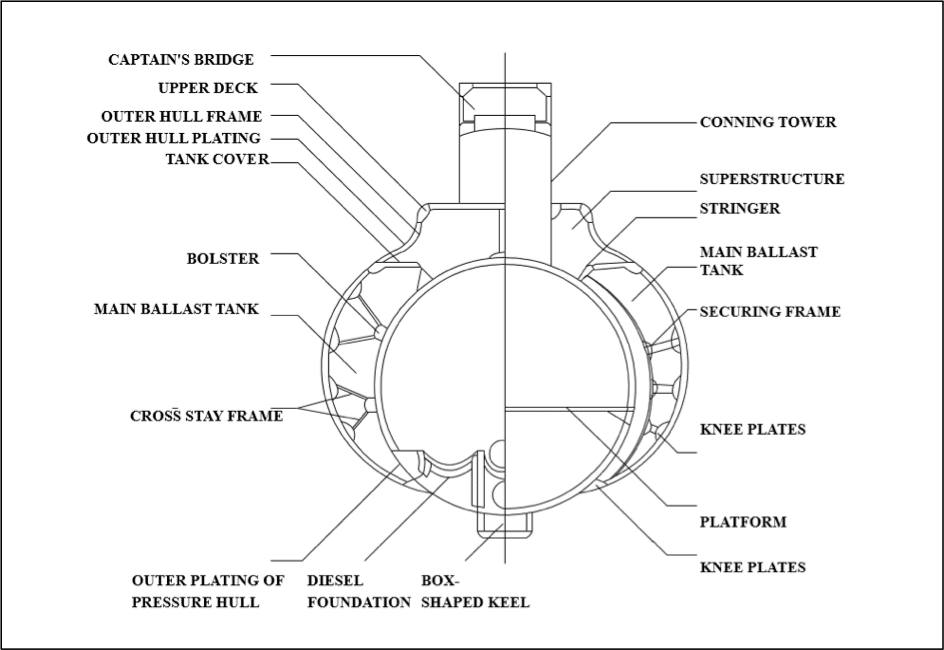

Just like a surface ship has a midship drawing, and drawings of structural components at all transverse frames, the following figure shows the structural components of a double hull submarine at a section that contains the sail. The right half of the drawing is the arrangement at an ordinary frame, and the part to the left of the centreline is a web frame (usually at three to five frame spaces).

Pressure Hull Penetrations:

The pressure hull is a pressure tight enclosed structure with atmospheric pressure within its enclosed volume. Even then, it is required to provide means to pass from inside to outside in both, surfaced and submerged conditions. For this purpose, circular hatches (conning tower at the centre, one hatch at forward and aft, each) are provided for access of personnel. Penetrations are provided for access of pipelines and cables that connect equipment which are housed outside the pressure hull but are actuated from inside.

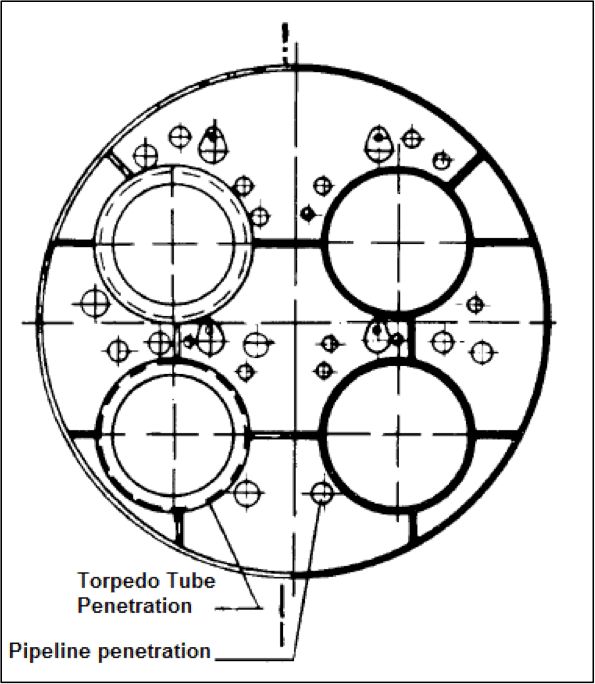

The forward elliptical dome bulkhead also has a number of penetrations, the primary ones being for the passage of torpedo tubes, and the secondary ones providing access to pipelines for the weapon compensating tanks. Penetrations on a forward bulkhead of a submarine is shown in the figure below.

These are very critical structures because they are unavoidable discontinuities on the pressure hull, and the edges of the penetrations (whether circular or elliptical) become points of high stress concentrations. Hence, welding processes of pressure hull penetrations is a highly scrutinised process and usually more than one type of non-destructive testing (NDT) is conducted on the welds of pressure hull penetrations.

Class of Structures on a Submarine:

Submarine structures are broadly categorised into three types depending on the effect their failure would have on the submarine.

Class I Structures: These are the structures which if damaged, would render the submarine completely incapable of carrying out any operation or remain afloat, and would also pose threat to the safety of the personnel. The complete primary structure of the pressure hull (the shell and the stiffeners) is Class I structure. Strictest NDT requirements are followed for certification of the quality of these structures. The pressure hull is also pre-tested to its design pressure by creating vacuum inside it, before other structural outfits are carried out on it.

Class II Structures: These structures if damaged or undergo complete failure would only hinder a part of the submarine’s capability of carrying out its mission. Though damage to Class II structures does not render the submarine inactive, it would affect a system or a part of a system that carries out a vital function in the submarine. Such damages are often repairable on board or by dry-docking the submarine. Class II structures also dictated by stringent NDT standards. Examples of these are ballast tanks, trim tanks, regulating and compensating tanks, pressure hull penetrations.

Class III Structures: Damage to Class III structures would pose no threat ot have negligible effect on the sea worthiness of the submarine. Such damages can be repaired while the submarine is in operation. Example of Class III structures are knee brackets, equipment supports, etc.

To conclude, the design and analysis of submarine structures is a process that is way more complex than that of ship structures due to the improbabilities of shock loads coming into effect. Every submarine design company conducts extensive finite element analyses for a combination of load cases that the structure could be subject to. What leaves scope of research in this field is, submarines are not tested projects like many surface ships. Each design is new depending on the navy and other inter-related requirements of the project, and this leaves the designers with a lot of scope to improve on the next.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

From where can i get lines plan and offset data of a sample submarine, i need to study the calculations. Thanks in advance.

Your articles on submarines for introduction purposes very interesting.

What are the units of measure for the minimum thickness of the hull for all the variables? Really hope you answer cause I can’t find anyone else to tell me.

@Steve: The unit used for hull thickness is “mm”.

Thanks for sharing a great informative article on Introduction to Submarine Design!

From where can i get lines plan and offset data of a sample submarine, i need to study the calculations. Thanks in advance.

And about the motor of submarine if some one do the submarine by yourself which motor to use it and how ?