What is Flexitank in Shipping?

Does your business require transporting large quantities of liquids or powders in drums or tanks? The conventional method of transporting these items is by metal or plastic drums, intermediate bulk containers also known as IBCs, or sacks made of plastic materials.

Is the cost of storage drums or tanks eating into your profits? Is sourcing a large tank container or a railway tank car a daunting task? If you answered Yes to any of these questions, a Flexitank is an answer for you.

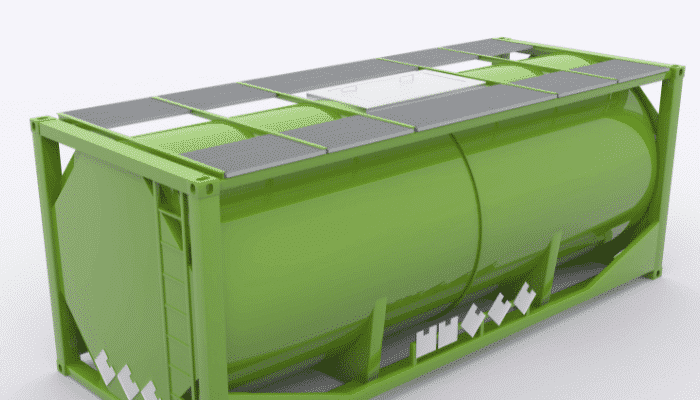

A flexitank is a solution for those organizations whose business involves bulk liquids such as edible oils, certain types of industrial oils, liquid latex, wines, juices, etc., or even powders. Almost any liquid that is not hazardous can be transported using flexitanks.

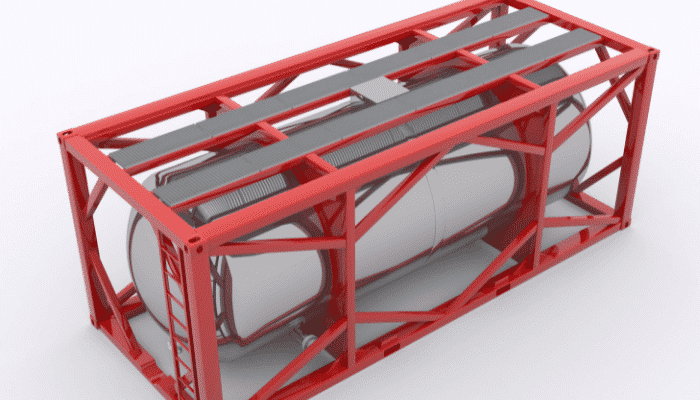

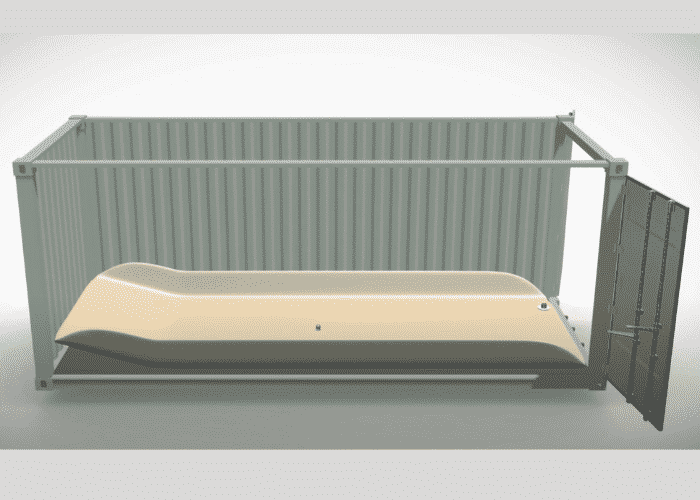

What is a flexitank? Imagine a large, soft plastic bag that can hold several thousands of litres of a liquid in it. It can be filled and emptied just as you would a soft, flexible pouch. In some countries, this is also known as a ‘flexibag’. When this flexibag is put inside a sturdy intermodal freight container, you have a flexitank!

So as not to complicate matters, here we will mostly be referring to the ‘flexibag’ as the flexitank.

The United States army is credited with having developed large flexible bags way back in the 1960s to transport water for the troops and diesel for their military vehicles. These bags evolved gradually over time to become the modern-day flexitanks.

Typically, a flexitank is made of durable FDA plastic material and it can normally hold up to 24000 litres of a liquid in it. It is made of several layers of this FDA plastic material to prevent accidental tears and leakage.

At least 2 – 3 inner layers of food-grade Polyethylene that are protected by a layer of woven Polypropylene ensures that the bag does not rupture and the liquid cargo stays safe.

Flexitanks are flexible, foldable, and can be hermetically sealed once it is filled with the contents. They are made to fit inside 20’ dry vans (20’ DV) that meet ISO standards. Liquids can be loaded as well as discharged from the top or bottom of these tanks, or both.

Liquids are filled and emptied using special pumps. The pump that is used for filling or discharge of liquids must be self-priming and positive-displacement pumps. Other options are air-driven or gear pumps. Centrifugal pumps should not be used.

Flexitanks normally have anti-suction ball valves on them to connect to a pump. These kinds of valves are effective in preventing leakage during the filling and discharge of fluids. They also prevent residue from being left inside the tank.

Certain flexitanks are equipped with automatic pressure-release valves. Such valves can be set to release the pressure inside the tank when it goes above a certain threshold. Later in this article, we will look at how pressure builds up inside flexitanks.

Once filled, flexitank containers can then be transported overland by road or rail or by sea freight.

Process of Using a Flexitank

Generally, the process of fixing a flexitank inside a freight container and filling it can take between 70 to 90 minutes. The fixing of the flexibag inside the container alone takes about half an hour with filling taking up the rest of the time.

How is this done? A new flexitank is positioned carefully inside the container and the liquid that is to be transported is pumped into it using a dedicated pump and hose. Once the tank is filled, it is sealed and a bulkhead or a sturdy frame to stop it from moving inside the container is placed near the container door. This bulkhead or frame also prevents the flexible bag from exerting pressure on the container door. Now the container is ready to be shipped.

However, the utmost care has to be taken while handling a flexitank. Installation of a flexitank has to be carried out only by experienced professionals. The container in which it is to be shipped has to be cleaned thoroughly and any sharp objects should be removed.

After cleaning, it must be confirmed that there is no rust or any lingering odours inside the container. After a final visual inspection and before putting the flexitank inside the container, the floor and walls of the container should be lined with a durable material such as a corrugated sheet, etc. This is to prevent the flexitank from getting snagged or damaged.

The staff who get inside the container for laying the lining material and placing the flexitank should not use shoes so that the materials are not damaged. Only a dedicated pump and hose should be used to fill the flexitank.

The standard filling rate that is recommended is between 600-700 litres per minute. In any case, it must not exceed 1000 litres per minute. While filling, care has to be taken that air is not pumped inside the flexitank. Once the filling is completed, the valve on the flexitank has to be locked correctly.

The flexitank manufacturer’s instructions should always be followed during handling, filling, and discharge.

Sometimes the liquid that is being transported may thicken due to the cold weather or because of the properties of the liquid. It may also thicken during storage.

This will result in difficulty during its discharge and may require mild heating using appropriate heaters or heating pads that can be positioned under the flexitank.

However, maximum caution has to be taken here to ensure that the flexitank is not damaged leading to ruptures or that the composition of the liquid does not change due to the application of excessive heat.

The loading staff has to ensure that the bulkhead and the valve of the flexitank do not touch the container door. As per PAS 1008 regulations, a container that is carrying a flexitank filled with liquid cargo should be marked to show accordingly.

What is PAS? PAS stands for Publicly Available Specification. PAS is a standard introduced by the British Standards Institute (BSI) to define good practice in matters relating to a product, service, or process. PAS influences and improves the quality of the industry.

PAS 1008:2016

PAS 1008:2016 which is the most current is a standard that is set for the manufacture of one-time use flexitanks that is used to transport bulk liquids so that it does not cause leakage or damage to the equipment.

This standard is followed by most leading flexitank manufacturers of the world.

Following the PAS 1008 standards makes flexitanks safe and benefits shippers, haulage companies, railway freight operators, insurance companies, etc.

PAS 1008:2016 lays down the criteria for the material properties of the flexitank material, its structure, and the effectiveness of its valves.

It also has stringent methods of testing the strength and durability of the flexitank to ensure that it withstands the handling, especially during filling and discharge.

Advantages of a Flexitank

Savings in Cost

More and more bulk liquid shippers are moving towards flexitanks these days. Compared to drums, tanks, and other types of containers used to transport liquids in bulk, they are much cheaper. Market research suggests 25% – 30% savings in cost by using flexitanks.

Ease of Use

They are much easier to use and there is a huge saving in time spent on loading and unloading the liquid cargo. Individual tanks take time to load and unload, fill and empty whereas the flexitank is filled or emptied in one go with the help of a pump and a hose.

More Capacity

Flexitanks can hold more volumes of liquid cargo. A flexitank inside a 20’ dry van can hold up to 24000 liters of a liquid in it. It can hold an estimated 30% more volume when compared to using drums or other types of containers.

Environment Friendly

The materials used in the making of flexitanks are recyclable and therefore there is zero wastage. The plastic material, as well as the other auxiliary parts of the bag, are normally recycled and there is no clutter, unlike drums and containers which may be made of different materials and therefore not easily recyclable.

Quality

A hermetically sealed flexitank preserves the freshness and quality of the product inside it.

Drawbacks of a Flexitank

Flexitanks, however, is not without drawbacks. Let us take a look at some of the issues here.

Selective Use

Only non-hazardous liquid cargo can be transported using flexitanks. Chemicals, corrosive liquids, combustible liquids, certain types of oils, etc. cannot be transported in flexitanks.

Size limitation

Currently, flexitanks are mostly made to fit only 20’ dry vans. It cannot be transported in containers of other sizes. Though there may be exceptions to this, currently it is very rare.

A 20’ container can be fitted only with a single flexitank. If there is more volume to be shipped than the capacity of a single flexitank, it will have to be transported in a separate 20’ container accordingly.

Hazardous if used Without Care

Flexitanks have to be used with care and according to instructions provided by the manufacturer. Any lapse during fitting, filling, or discharge can lead to accidents or damage to equipment.

Selective Usage after Recycling

Taking quality issues into account, even though a flexitank can be recycled after use, it cannot be recycled to be used again in the manufacture of flexitanks.

Types of Flexitanks

Flexitanks have evolved to meet the varied needs of the different industries. The different types of flexitanks that are available in the market today are mentioned here.

Flexitanks to Address the Issue of Sedimentation

It may be difficult to empty liquids that leave sediments at the bottom of the flexitank during storage and transport. A kind of pulse technology that allows the liquid to be mixed or agitated before discharge, is available to empty the tank easily. The structure of these tanks in most cases prevents sludge from being deposited in the corners. The valves are located at a lower level on the flexitank for ease of discharge.

Liquids that Require Heating for Easy Discharge

Fluids with high viscosity may need to be heated lightly before discharging from the flexitank. Such liquids will need special flexitanks made of at least 3 layers of Polyethylene, that can withstand the heat safely from heater pads or other such compatible accessories.

Extra-large Flexitanks for Transporting Extra-large Volumes of Liquid Cargo

Though not very common, for shipping very large quantities of liquids, very large flexitanks that fit a 40’ dry van or a 40’ reefer are also available. These are used mainly to transport dairy products, beer, fruit juices, etc. Transporting in a refrigerated container means that the temperature can be controlled according to the requirement of the cargo.

Extra Levels of Protection for the Cargo

Depending on the liquid to be transported, specialized flexitanks with extra levels of protection from contaminants are available.

The protection offered by specialized flexitanks includes gas barriers and minimum air and water vapour transmission that helps to prevent or reduce oxidation of the liquid inside.

Some liquids produce gas when they are stored over a period. Wines are an example. Wine produces carbon dioxide during fermentation.

This can be extremely dangerous especially when it is stored and transported in a flexitank of poor make. It can cause bulging of the flexitank and in very rare cases, even an explosion.

To prevent such instances, modern flexitanks are equipped with automatic pressure release valves that can be set to release the extra pressure inside the tank when it goes above a certain level.

It is important that transporters use flexitanks that are made by reputed manufacturers and are certified by agencies such as the BSI.

Just as with any other equipment, a flexitank is convenient and safe if it is used following instructions.

An interesting fact that I must mention here is that flexitanks with their large capacity for holding liquids are known to be used for purposes other than transport of the liquids mentioned above.

It is used for fighting fires in remote places where firefighting equipment like fire hydrants and hoses may not be available. They are used to carry and store water for combating bush or forest fires!

You might also like to read:

- 16 Types of Container Units and Designs for Shipping Cargo

- Flat Rack Containers – Types, Specifications And Dimensions

- Container Seals – Importance, Types, And Requirements

- What Are Insulated Shipping Containers?

- How Are Shipping Containers Made?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

Hari Menon is a Freelance writer with close to 20 years of professional experience in Logistics, Warehousing, Supply chain, and Contracts administration. An avid fitness freak, and bibliophile, he loves travelling too.

Latest Maritime law Articles You Would Like:

Latest News

- Why Dry Ice Is Used For Packaging

- What is the Purpose of DG Shipping?

- What are Logistics Risks?

- How Port and Terminal Operators Can Control Emissions?

- Minimum Quantity Commitment (MQC) and Liquidated Damages in Container Shipping: Concept and Relevance

- MARPOL (The International Convention for Prevention of Marine Pollution For Ships): The Ultimate Guide

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.