20 Points Engineers Onboard Ship Should Consider While Planning For a Long Voyage

If a ship is scheduled for a long voyage, the deck and engine room departments need to properly plan their duties for maintenance and operation of the ship. As a responsible personnel of the ship’s engine room, the engineer has to meticulously plan his duties (especially if he is a chief engineer) before the long voyage starts. The planning of inspections, checks, maintenance of the ship’s engine room needs to be done properly, considering the Planned Maintenance System (PMS) and associated areas under the ISM code.

Mentioned below are 20 important points that needs to be considered by the ship’s engineer before the start of the voyage:

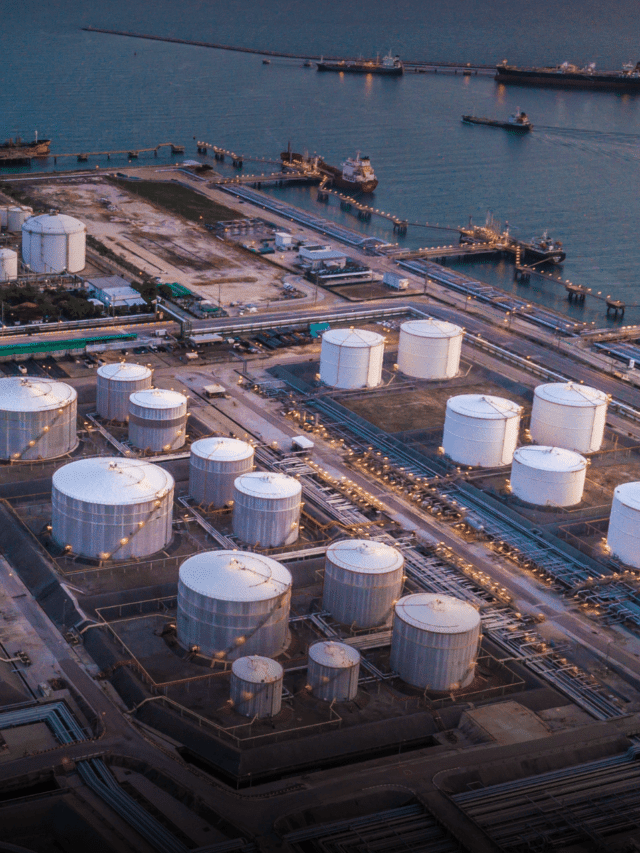

1. Sound the Tanks : All important tanks such as fuel oil, diesel oil, gas oil, lube oil etc. should be properly sounded to confirm that the actual figures match with the log book figures. Soundings should be properly taken and noted down.

Read: 3 Important Calculations Every Marine Engineer Should Know

2. Plan for Expected Bunkers: Proper planning needs to be done by discussing with other engineers on bunkers that have been scheduled during the voyage. All safety precautions should be taken for carrying out bunkering at the sea.

Read: 15 Practical Tips For Bunkering

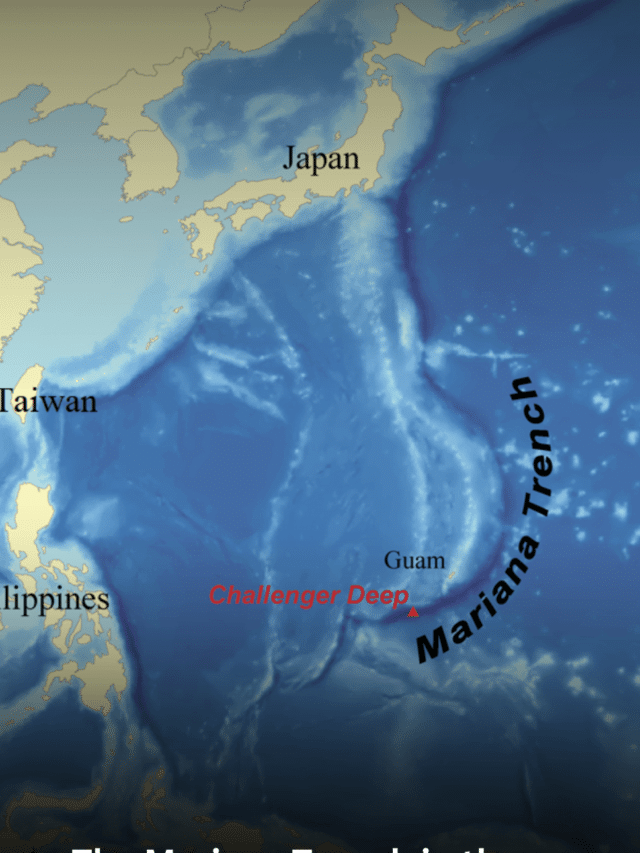

3. Check Voyage Plan for Expected Emission Control Areas (ECA): Check the voyage plan to know what emission control areas the ship will be entering. If the ship is going to pass through one, prepare for a Low Sulphur Fuel Oil (LSFO) tank or ensure exhaust gas scrubber and similar machinery arrangement are working fine.

Read : 10 Technologies For Reducing NOx and SOx from Ships

Fuel Oil Change Over Procedure For Ship’s Main and Auxiliary Engines

4. Ensure Voyage Requirements: Check all engine room voyage requirements are on board before the ship leaves the port. Engineer should also find out about the consumption patterns of all important things and provide special instructions to the concern people regarding the same. Also study the vessel’s sailing program and plan the voyage accordingly.

5. Check Handling Over Report: Read the handing over notes of previous engineer thoroughly and give extra attention to the remarks and systems that have been recently repaired or considered troublesome.

Read: How to Write An Handing Over Report?

6. Check Oil Record Book: Oil record book needs to be thoroughly checked. Also ensure that all pages are signed by the chief engineer and master.

7. Check for Overdue Certificates and Surveys: In case the engine room is schedules for overdue certification and surveys, make sure that the planning that is to be carried out properly includes them.

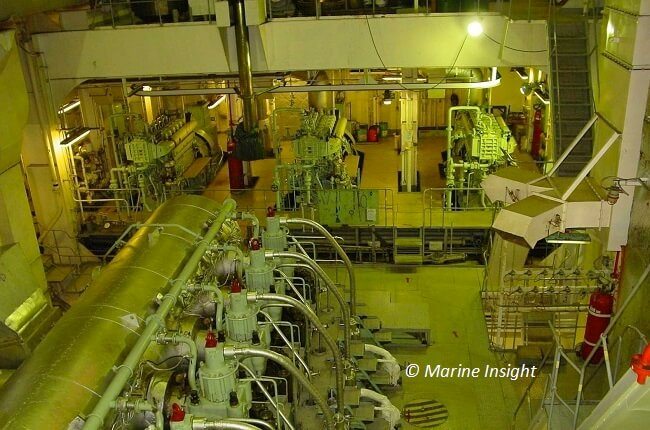

8. Check Main And Auxiliary Machinery: The status and condition of the main engine and auxiliary machinery should be assessed and all scheduled maintenance jobs to be carried out are properly noted.

Learn correct procedures for starting and stopping engine room machinery and systems without marine any error. Get the complete step-by-step checklist. Click here to know more about the eBook.

Learn correct procedures for starting and stopping engine room machinery and systems without marine any error. Get the complete step-by-step checklist. Click here to know more about the eBook.9. Record of Running Hours: Since machinery maintenance is on the basis of running hours and time based, ensure that the record of running hours is properly collected and checked.

10. Check For Spares: Check whether engine room inventory is updated and minimum number of of spares are available on board at all times for carrying out maintenance as per PMS. If required number of spares are not enough, then indent should be raised at the earliest for the same.

11. Check For Stores: The ship should have all necessary stock of stores on board. Inventory should be updated and requisition should be raised as soon as possible when required.

12. Check For Pollution Prevention Equipment: Pollution prevention equipment such as Oily Water Separator (OWS), Sewage Plant, Incinerator and associated pumping systems are in order and working fine.

13. Check Special Areas And Sewage Discharge Laws: Check special areas which will be crossed during the voyage and ensure all engine room personnel know the MARPOL regulations. Also know all local regulations for sewage discharge for coastal waters in the up-coming voyage including next port of call and inform the engine room personnel about the same.

14. Plan Sludge And Waste Discharge: Calculate the estimated sludge and bilge production that will be generated during voyage and plan for sludge discharge in the next port of call accordingly.

15. Secure All Heavy Articles in the Engine Room: The ship may encounter heavy weather and it’s always easy to secure heavy weights when ship is at port using cranes or other equipment.

16. Prepare for Port State Control: All necessary preparations for the port state control should be carried out well in advance. Every ship has to go through port state control surveys and the crew should ensure that all common deficiencies that are checked are taken care of. All the previous records should also be checked and studied.

Read : 10 Things PSC Inspector Can Check In The Engine Room

A Step-By-Step Guide to Overhauling Generators on Ships is a digital book which explains the Generator D’Carb Procedure in a practical way. From planning to running-in and inspection, the guide provides a detailed explanation of all the aspects involved in major overhauling of generators on ships. Click here to know more about the eBook.

A Step-By-Step Guide to Overhauling Generators on Ships is a digital book which explains the Generator D’Carb Procedure in a practical way. From planning to running-in and inspection, the guide provides a detailed explanation of all the aspects involved in major overhauling of generators on ships. Click here to know more about the eBook.17. Check Files and Maintenance Records: Ensure that all important and official files related to the machinery and ship operations are properly labeled and indexed. Maintenance records of jobs carried out by the ship’s staff/ workshops should also be checked and filed properly. Records of CSM (Continuous survey of machinery), equipment certificates and makers certificates are also important and should be checked for order and validity. In case there is any deficiency, it should be reported to the superintendent and necessary changes should be made at the earliest.

Also, check that all the maintenance carried out during each month is properly entered in the log abstract and forwarded to the concerned superintendent every month. Renewal of major components, breakdown repair, detection of any cracks, other defects should also be highlighted in the abstract. Ensure that all important documents that are checked in port state control (PSC) are properly checked and easily accessible on board.

Read : 10 Ways To Know Engine Room Machinery Better

18. Ensure Drawings and Manuals Are Present: All necessary drawings and instruction books needed for reference should be present on board, properly secured and indexed. All necessary amendments should be made to the drawings and instruction books in case of any structural change, modifications, renewal, retrofit or decommissioning of any equipment. This changes should be done with permission of the superintendent or other concerned authority.

19. Test Alarms and Safety Devices: In order to ensure proper operation of the safety equipment and alarms, engineers should randomly test them at regular intervals of time. Audio-visual alarms/cut-outs and auto starting of equipment, should be tested, wherever possible. Simulation test such as Lube oil pressure, low cool water pressure, cut-outs, boiler water low alarm and low-low water cut-out should also be checked regularly. Alarm devices should not be bypassed under normal running conditions; but if bypassed due to some reason, all concerned personnel should be informed about the same.

20. Ensure Engine Room Crew is Familiar With All Operations Ensure that all engineer officers are familiar with PMS operations of all machinery and systems, operations of all safety equipment, and safety and environmental protection policy of the company.

Read: 10 Important Safety Drills And Procedures For Engine Room

A thorough planning of ship’s maintenance and operational procedures require several important aspects to be taken into consideration in the ship’s engine room. The above mentioned points is not an exhaustive list but provides a general overview of the most common points that must be taken into account.

Over to you..

Do you know any other important point that must be added to this list?

Let’s know in the comments below.

Latest Shipboard Guidelines Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Nice job

As an Ex-Master Mariner I have developed software programs for Cargo & tanker Ships

see Bunker Survey Generator & AstmTablesCalc at my website at : http://www.zakos-cargo-calc.com

the health, and the capacity of the crew must be fit, to stand in a long voyage can be considered important

I think we should also consider the health of the crew and the cleanliness of its working environment 🙂

Awesome title. Thanks.

You have presented a nice list of points. However, nearly every point is a part of Ism, a routine that be undertaken regularly and routinely and not specific to a lengthy voyage.

These points are regular items regardless of the voyage length.

The Independent Hull and Machinery Consultancy (IHMCo)

I think it is also abviceable to take proper look at or checks on steering system regard ateering room for proper starboard and astern movement to the full capacity before sailing thanks.

Check fresh water and fiters for the water.We use bottle water for drinking and cooking but if tanks are good and water your getting is OK there no harm in using.Most have filters for the water that need to be changed like any other