What is a Hull Roughness Analyzer and How is a Ship’s Hull Roughness Measured?

A Ship’s hull roughness is a very important factor, which directly affects the power and fuel consumption of the ship’s main engine. Hull roughness of the ship is measured from time to time, mainly during dry docking of the ship.

Measuring Hull Roughness

The hull roughness of the ship can be determined by a tool known as hull roughness analyzer or similar instrument for those ship which are not coated with silicon based foul release paint coating.

If the ship’s hull is coated with silicon based paint, speed trails are done to determine hull roughness which gives changes in the performance and speed of the ship.

Understanding Hull Roughness Analyzer

A Hull Roughness Analyser (HRA) consists of a portable microprocessor along with a digital printout and display unit.

A computer is connected to the hand held carriage having a stylus measuring head.

The stylus head is moved around the hull surface to measure and record the hull roughness profile.

The short wave roughness is the diameter of the stylus tip. The long wave cut off is set at 50 mm.

Working of Hull Roughness Analyzer

One traverse of the head at any point on the hull will collect information from 10 samples having length of 50 mm.

For each 50 mm sample, the micro processor will assess the mean gradient through the peaks and valleys to give highest peak to lowest valley measurement for that sample.

This measurement is known as Rt (50).

The roughness check covers approx 100 selected locations which must include bow, stern, mid ship, and boot topping area (area between load line and ballast water line).

A number of traverses for the stylus will give ‘n’ readings, hence the Mean Hull Roughness (M.H.R) at that station is average of

Rt (50) i.e.

M.H.R = ∑Rt(50)/ n

There will be ‘m’ stations around the hull of the ship. Hence Average Hull Roughness (AHR) will be average of Mean Hull Roughness i.e.

A.H.R= ∑M.H.R/ m

Normal Duration for Analyzing Ship’s Hull

- When the ship is new, before launching the ship, hull surface roughness is checked which become a reference value of that ship.

- When the ship comes in dry dock and before the maintenance process is started on the hull. This gives the deterioration value.

- Before Undocking to measure or compare the hull after maintenance procedure is completed.

Typical Roughness or A.H.R of a ship when it is new is approx 120 microns.

Due to fouling and deterioration, an 8 year old ship will have A.H.R in the range of 300-400 microns.

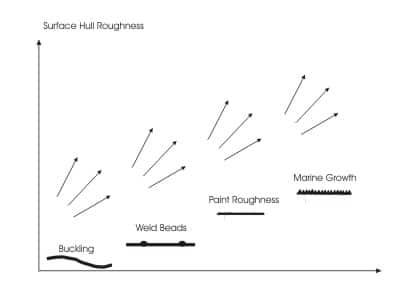

The significance of the roughness profile is that increase in the hull roughness will increase the frictional resistance of the ship. Since this is the major aspect of resistance for a merchant ship, this will increase the power, fuel consumption and operating cost of the ship.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

what is vessel’s enhanced survey profile?

can be done underwater also by means of divers.

Also classification approved.

Could you please advise of any roughness analysers which can be used underwater, and which classification society has approved the process.

how to measure the hull roughness by means of BSRA procedure?

thanks

Wet measuring may not give true results.Most of the antifoulings will be more soft in the water.There must be a determination with dry readings and/or maker specs.should be used for corrections.