What are Container Ships – History, Types And Design

What are Container Ships?

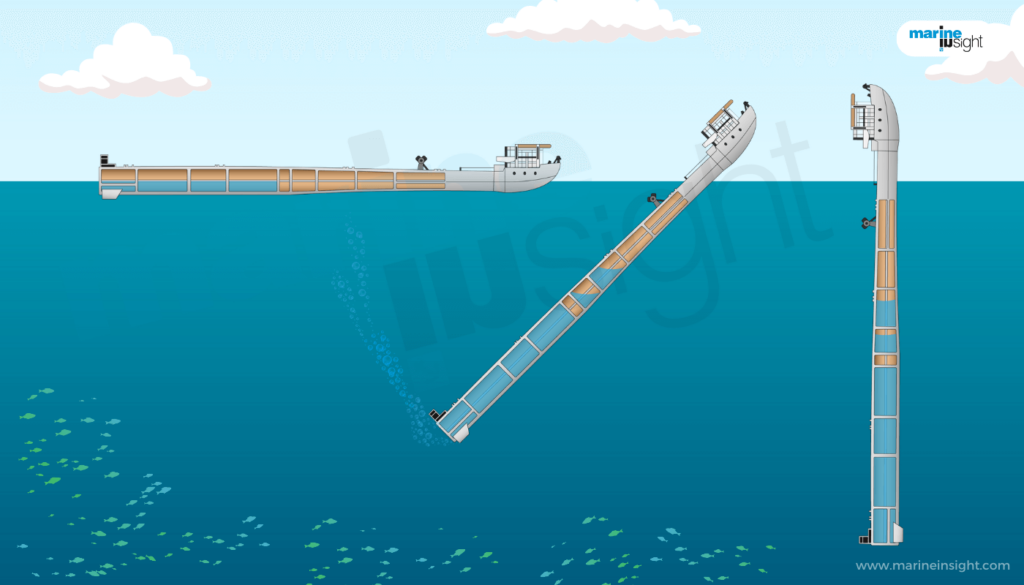

As the name suggests, a vessel structured specifically to hold vast quantities of cargo compacted in different containers is called a container vessel (ship). The process of sending shipments in special containers is known as containerisation.

One of the most powerful methods of hauling goods is done by Container Ships. These ships have made it feasible to transfer high quantities of cargo at a time and have changed global trade efficaciously.

Container ships are the cargo ships that carry most seagoing non-bulk cargoes. In today’s world, container vessels have around 90% of the world’s non-bulk cargo. One of the main ways of carrying ready goods worldwide is through Container Vessels. These containers are of a standardised size so that they can be easily transferred to various modes of transport. Anything can be carried on a Containership.

Related Read: A Guide to Shipping Container Dimensions

Because of the increasing demand in the market, increasing cargo-carrying capacity, increasing operating efficiency and improvement in environmental processes and operation of a container vessel in liner service, the container vessels have continuously become bigger.

The container carrying capacity of container ships today has increased more than 1200% compared to 1968. They have become more technologically advanced and fuel-efficient over time.

History of Container Ships

The initiation of container shipping forms one of the most remarkable developments in the maritime cargo industry. Container ships, a type of cargo ship, have revolutionised how cargo supplies are ferried and transported across the world by assuring the safety and security of the thus transported cargo supplies. Today, some of the biggest shipping companies deal mainly with the containerised form of cargo.

The first models of container ships were launched in the early 1950s and were mainly designed to ferry goods trains’ freight cars. Using crane and ramp systems, these freight cars could be loaded and unloaded from the vessels.

Over the years, technological advancement has made it possible for comparatively far more feasible methodologies. However, crane systems still play a significant role in the loading and unloading operations of the containers to and from the vessels’ holds. Specialised lashing and cargo handling systems are used to secure the containers in their places.

Related Read: What is an Intermodal Container?

Container vessels are typical in that they are constructed to accommodate immense possible cargo loads. The load holding capacitance of container vessels is measured in terms of Twenty-foot Equivalent Units or TEUs, with the giant container ships carrying as much as over 15,000 -16,000 TEUs.

Because of such high capacities, some of the largest ships in the world are container ships.

Types of Container Ships

Container vessels can be classified in many ways:

Development Generations

Containers vessels have been through various phases. These phases have been classified as generations.

- First Generation – 1956 TO 1970

- Second Generation – 1970 TO 1980

- Third Generation – 1980 TO 1988

- Fourth Generation – 1988 TO 2000

- Fifth Generation – 2000 TO 2005

- Sixth Generation – 2006 TO TILL DATE

Related Read: Top 26 Innovative Uses of Shipping Containers

Handling Modes

LoLo Container Ships

Lift-on/Load-off vessels are Geared container vessels which can load and discharge the cargo using the ship’s crane.

They can operate without port cranes and can do cargo operations unassisted.

Related Read: Container Gantry Crane: Construction and Operation

ROCON Container Ships

ROCONs are ro-ro vessels that also carry containers. The arrangements are such that the containers may be loaded on the deck, or there is a separate hold specifically for loading containers.

Related Read: What are Ro-Ro Ships?

Container Ship Sizes

- Panamax

- Suezmax

- Post-Panamax

- Post-Suezmax

- Post-Malaccamax

Panamax

- Panamax size vessels were first introduced in 1980.

- These vessels were of around 4000-5000 TEUs.

- Their dimension was such that they could pass the Panama canal. They were limited to the max length of 294.1m, Breadth of 32.3m and max draught of 12m, which was par compared to the canal’s dimensions.

Post- Panamax

- APL introduced a new transportation net without using the Panama Canal. This created the ‘Post-Panamax’ type. The Introduction of Regina Mærsk in 1996 started a new development in the container ship market with an official capacity of 6400 TEU.

- Post-Panamax’s development was climactic. In the present world, they occupy nearly 30% of the world’s fleet.

- These sizes of vessels were subversive, introducing new ideas and methods in the container shipping market.

- The concept of cellular container vessels was introduced. The cell guides ran from the bottom of the hold to some tiers above the deck. This reduced the running cost of ship owners as no lashing materials were used to secure the containers but also improved the speed of loading and discharging and reduced container shifting.

Suezmax

- Suezmax max-size vessels were introduced about the Suez canal. These vessels have nearly the same size as that of the Suez canal.

- Suezmax vessels have a carrying capacity of around 12000 TEUs, with a Breadth of about 50-57 m and draught between 14.4m-16.4m.

Post-Suezmax

- These are Ultra-large container vessels with a carrying capacity of 18000 TEU with a breadth of 60m 21m max draught.

- These vessels are known as Post Suezmax as their dimensions are too big for the vessel to pass the Suez canal.

Post – Malacamax

- This size emulates the maximum permissible draught of 21m of Malacca Strait.

- The port authorities must be ready for this vessel to enter the Ports. Presently only two ports in the world are prepared to accept this size of ship, i.e., Singapore & Rotterdam.

Container Ships Service Range

Feeder Ship

- These ships are used for short routes. The voyages are no longer than 500nm and only trade in the coastal areas.

- The Capacity of such vessels does not exceed 1500TEU.

Mother Ship

- These are the vessels that are in international trade.

- The size of these vessels is much bigger than feeders.

Basic Design Of Container Vessels

The design of the accompanying container vessel is decisive. The hull is akin to the conventional Bulk Carriers and General cargo ships built around a firm keel. The lower part of the vessel has a significant effect on the construction of the ship. There are lower decks, an Engine room, great ballast, and Fuel Tanks. The Cargo holds are the places where the underdeck Containers are loaded.

Inside the hold, cell guide arrangements guide the container to slot well. This helps the crane operator safely slide the container inside the handles and acts as a guide. It is imperative to maintain this cell guide well. Any damage to the cell guides may lead to critical consequences. These holds are topped by hatch covers, above which the containers are stacked.

Most modern container vessels do not have cranes, but some have cargo cranes installed on them, especially in vessels of smaller sizes. Vessels with cranes are called geared container vessels, whereas vessels without cranes are called Gearless container vessels.

Related Read: Understanding Design Of Container Ships

These geared container vessels use them for self-loading and discharging at ports where the cargo volume is low. There are also some specialised systems for securing the containers onboard.

In most container vessels, lift-away types of Hatch covers are used. Hatch covers to increase the ship’s carrying capacity and prevent water ingress inside the hold & fissure, the containers under-deck and on deck both. These hatch covers have cleats that must be closed after every cargo operation & before the vessel departs from any port.

Related Read: Important Points for Safe Container Lashing

Also, within a container ship, well-demarcated holds separate each container from the other, simplifying the entirety of the filing of the containers.

- In essence, container ships are regarded to be a generic reference. Within their ambit, there are several different types of container ships. Each container vessel is unique and different, with an undiminished operational singularity.

- Container ships explicitly built to fit into the Panama Canal channels are called the Panamax container vessels. These ships can be loaded with a maximum TEU of about 5,000 and measure slightly over 290 metres lengthwise.

- The slightest variance of container vessels is the Small Feeder type. These container vessels can carry loads up to 1000 TEUs. Several developments made to the Feeder categorisation have resulted in the development of the categories of ‘Feedermax’ and ‘Feeder.’ The former can carry a maximum of about 3,000 TEUs, while the latter can carry around 2,000 TEUs.

Container shipping vessels represent a majority in terms of the packaged cargo ferried across the world. On account of the relevance and the ever-increasing demand for better maritime cargo transportation channels, there have been considerable strides in the container ships’ domain. Such advancements are expected to grow even more in the days to come.

Types Of Containers

- ISO containers, also referred to as intermodal containers, are used to transport freight. ISO containers are designed for transportation by more than one mode: truck and rail or rail and ship.

- These freight containers conform to the International Organization for Standardization (ISO) container manufacturing standards.

- ISO is an international standards organisation headquartered in Geneva, Switzerland. ISO containers are produced in several standard configurations, including dry (or cube), insulated, flat rack (or platform), open-top, refrigerated, and tank. Dry ISO containers are general-purpose, totally enclosed, box-type containers used for general-purpose transportation.

- ISO containers are manufactured in standard sizes. The standard width of ISO containers is 8 feet, the standard heights are 8 feet 6 inches and 9 feet 6 inches, and the most common lengths are 20 feet and 40 feet.

- The use of 45 Feet containers has also increased significantly.

Types Of Containers By Design

- Flat Rack Container

- Dry Van Box Container

- Tunnel Container

- Side Open Container

- Cylindrical Tank Container

- Thermal Container

- Open Top Container

- Refrigerated Container

Read More: 16 types of container designs here.

Future Of Container Vessels

Container vessels represent a majority in terms of the packaged cargo ferried across the world. On account of the relevance and the ever-increasing demand for better maritime cargo transportation channels, there have been considerable strides in the container ships’ domain. Such advancements are expected to grow even more in the days to come.

In the coming days, container ships have many more challenges to face, but the Container shipping industry will always stand firm. Upcoming changes in rules/regulations, increasingly stringent environmental laws, a competitive market, the Introduction of new technologies, and an increase in marine traffic about the increased carrying capacity of the vessels will be its preeminent problems.

Frequently Asked Questions

1. What are containerships?

A vessel structured specifically to hold vast quantities of cargo compacted in different containers is called a container vessel (ship). The process of sending shipments in special containers is known as containerisation.

2. When were the first container ships launched?

The first models of container ships were launched in the early 1950s and were mainly designed to ferry goods trains’ freight cars. Using crane and ramp systems, these freight cars could be loaded and unloaded from the vessels.

3. What are the different sizes of container ships?

Container ships are categorised into seven major categories, depending on their size. These include Small feeder ships, feeder ships, feeder max, Panamax, Post-Panamax, New Panamax and Ultra Large.

4. What are the different types of container designs?

There are many kinds, including the Flat Rack Container, Dry Van Box Container, Tunnel Container, Side Open Container, Cylindrical Tank Container, Thermal Container, Open Top Container and Refrigerated Container.

5. Why are container ships getting bigger?

Container ships are becoming more advanced and bigger due to Increasing market demand and cargo-carrying capacity, greater operating efficiency and improvement in environmental processes and shipping operations.

You may also like to read:

- Top 10 World’s Largest Container Ships In 2020

- Understanding the Design Of Container Ships

- What is Parametric Rolling in Container Ships?

- Different Cargo Handling Equipment Used on Container Ships

- Container Seals: Importance, Types, And Requirements

- What Are Supramax Cargo Vessels?

Disclaimer: The author’s views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Type Of Ships Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

There is a solution to the problem of the above deck load of containers breaking off laterally over the side of the ship..The motion of a ship in roll is far greater than it is in pitch. Therefore if the containers were loaded 90 degrees rotated to the normal method, the container loaded lengthwise across the ship, the stack of containers would be much more stable laterally and naturally resistant to breaking away in severe roll.

This article is just impeccable. Very nicely written and detailed.

Each and every information provided here is correct and precise.I have been a Master from last 18years,but have always sailed in Gas tankers. Reading this gave me a clear information about the Container vessels.Very well done team Marine Insight. A big thanks to the person who has written.

@Capt. Yuri: Thank you for your appreciation and support. ☺️

Hi… Sir/Mdm,

Please advise.

Can I have how to apply jobs vacancy at this industry line.

Very well presented

Glad you like it 👍