What is Anchor Chain – Everything You Should Know

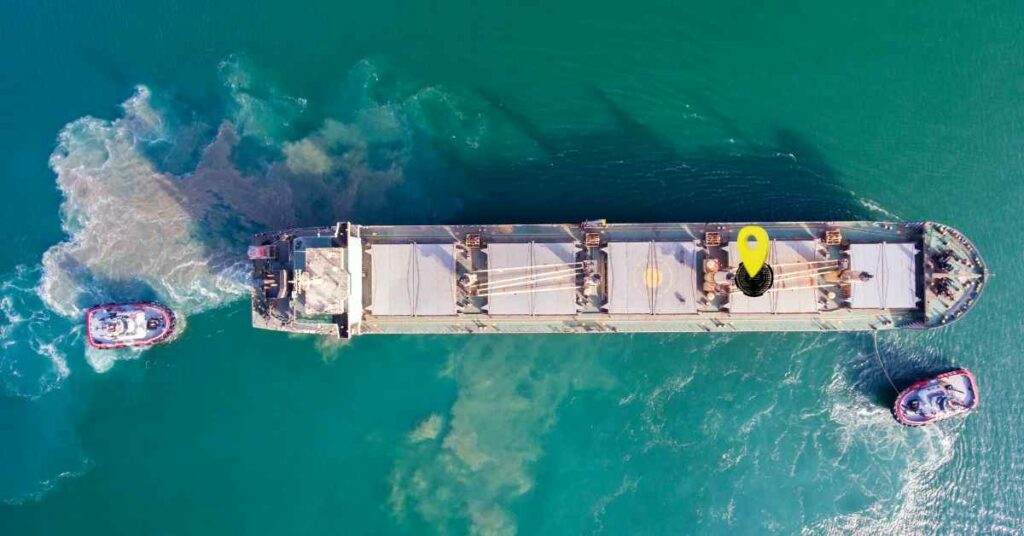

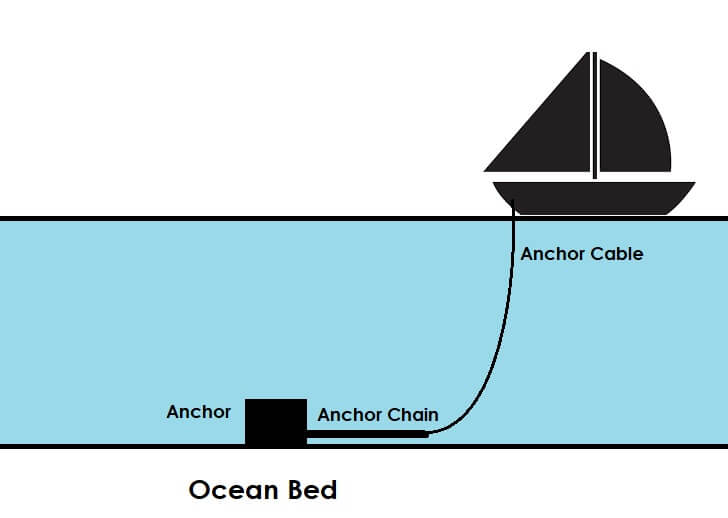

As we learned in the article on types of anchors, nautical equipment that is used to restrict structural or vehicular movement in the water using a combination of weight and friction along the bed of the ocean or seafloor is known as an anchor.

Its primary purpose is to provide a mechanism for ships and boats to hold their position either during berthing and mooring operations at ports, or for large offshore installations such as semi-submersible oil rigs to remain stationary above an oil deposit.

To do so, the anchor grips on to any rocks or debris at the bottom of the ocean or sea, to provide a pivot about which the vessel will remain stationary.

Along with this, anchors can also increase the drag of any vessel in situations where it is so required. When trailing behind the ship, they serve as an artificial drag mechanism.

By letting the anchor follow in the wake of the ship, the entire vessel is stabilized against any abrupt wave motions during storms. This is a key factor in preventing green water loading and bow slamming. Green water is a technical term for any water present on the upper deck of the ship.

Bow slamming refers to the large forces exerted on the fore hull of the vessel by waves during storms. By allowing the anchor to absorb huge amounts of load and redirect forces away from the hull of the ship, the vessel can remain relatively stable even during unfavourable conditions.

Importance of the Anchor Chain

As seen, the anchor plays a major role in a vessel and offshore operations. However, it can only function as long as it remains attached to the floating structure.

Considering the tremendous amounts of force applied to the connection between the anchor and the ship during routine berthing or anchoring conditions, conventional methods of securing the anchor will eventually fail under the extensive stress.

The anchor chain refers to the component that attaches the anchor to the boat or structure and is usually referred to as the anchor rode (or anchor cable). It is superior to conventional methods in terms of strength and load-bearing.

The purpose of the anchor rode is to secure the anchor to a part of the vessel in such a manner that it can be easily hauled up when the need arises.

It also plays a major role in absorbing a certain portion of forces away from the main structure and anchor head. For instance, during storms or other similar weather conditions, the vessel or offshore rig tends to pitch and heel. This motion can intensify, causing damage to the vessel.

To dampen these forces, the anchor rode is designed to absorb a certain amount of the load. Since anchor chains and cables are built to withstand large forces on them, they are not drastically damaged or deformed by such loads. This absorption of forces away from the main structure and anchor is known as dampening.

Important factors to keep in mind while selecting or designing the anchor chain are the

- maximum permissible loads,

- ease of storage, and

- the expected length of the rode.

The stresses need to be checked for every unit of the rode. Metal chains have links as their primary unit component, while ropes and cables have fibres.

Ease of storage is another key factor in rode design. If the anchor rode cannot be reeled back in and then stored securely, it could lead to damage of the hull.

Every vessel or offshore installation has a rough idea of the operating locations, and consequently the maximum and minimum depths of the waterbodies at these locations. Based on these, the anchor rode is manufactured at a particular length at which it must be securely fastened.

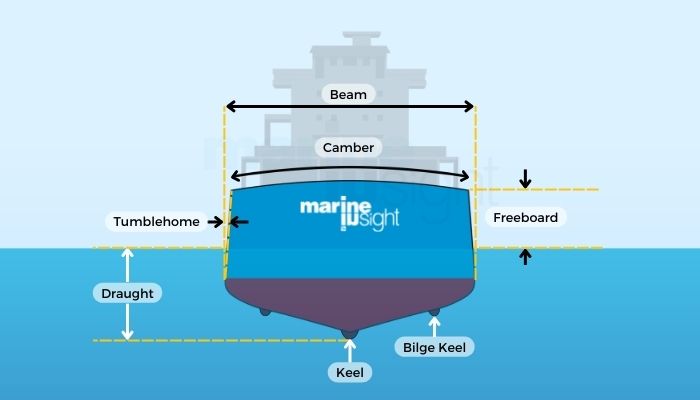

The ratio of the length of the anchor rode paid out, and the actual depth of the waterbody is known as the scope. It represents a trade-off between vessel drifting and vertical forces on the anchor.

Scopes are usually in the range of 5:1 to 7:1. Shorter rodes have lesser slack, hence the ship does not easily drift off due to the natural wave motions. However, since the angle between the seabed and anchor rode is nearly ninety degrees, shocks and jerks are directly transferred to the rode and subsequently the vessel.

If the scope is increased beyond a certain value, it would drastically decrease the forces on the vessel, but would also allow the vessel to drift out into a larger region.

Forces on the Rode (Or Anchor Cable)

To decide the material and structural requirements used while designing the chain, it is important to analyze the various forces acting on it. The major forces acting on the rode include tensile, compressional, vibrational, torsional, thermal and chemical forces.

Tensile forces refer to loads that attempt to elongate any structure in the longitudinal direction. Conversely, compression refers to loads that contract the entire structure.

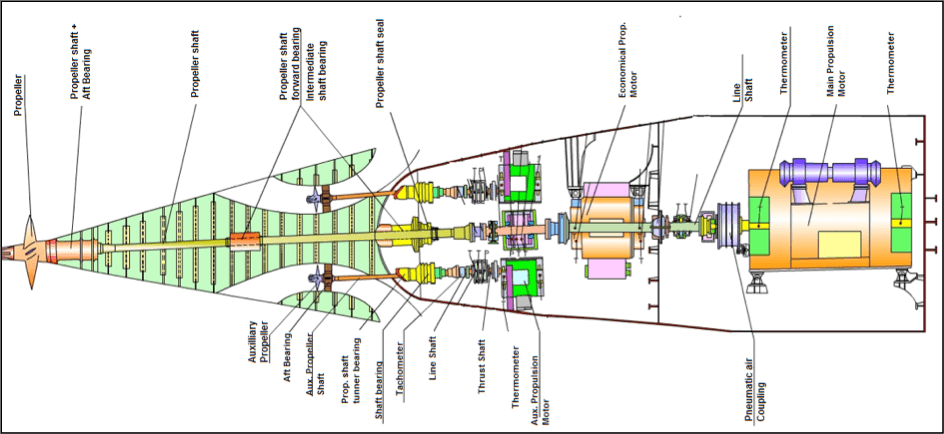

Vibrational loads arise due to machinery and other vessel components that have high frequencies of operation. For instance, the anchor chain located near the engine is subject to large strains since the engine vibrates at a high rpm.

Torsion refers to the twisting of a structure when one end is kept fixed. This causes distortion when the individual links or fibres get knotted. Since a large weight acts at the other end of the chain, deformations can occur.

Thermal forces arise because of temperature changes that occur near the anchor. Between the day and night, varying weather conditions could heat or cool the rode. This hot-cold cycle can induce thermal stresses that cause material fatigue. Lastly, chemical forces occur due to the corrosion of the material forming the rode, either due to rusting or because of exposure to organisms in the water.

The right blend of materials must be used to manufacture the anchor rode. Broken connections can be extremely dangerous during berthing operations for ships and offshore installations. Two common methods of designing the anchor are used: metal links known as chain rode or ropes known as an anchor cable.

Anchor Cable/Rope

In this type, the individual units are fibres running along the length of the entire rode. They are twisted for added strength and are often covered in some form of the sheath.

These types of rodes are extremely lightweight and flexible since they are essentially made of rope. Also, they can absorb large amounts of loads because of the high yield stress. However, the biggest disadvantage of using anchor cables is that they are prone to chaffing and can wear out easily.

Rubbing against underwater debris, or friction generated between adjacent cable fibres are major causes of this form of degradation. Another common problem with this type of anchor rode is that it can split apart when the internal stresses exceed the permitted levels.

These types of anchor rodes are used for small boats, watercraft, and lightweight vessels. Larger structures place undue stress on the fibres that may result in them giving away in the middle of an operation. There are several methods of manufacturing anchor cables that are more resistant to loading.

The most common type of cable is the twisted cable. Two or more individual cables are twisted against each other until they form a single, strong cable. The benefit of this method is that it increases the strength without increasing the production time considerably.

The issue is that there may be the partial unravelling of the cable when forces are applied on it. The second type is the braided and double braided cable. In this style, the individual fibres are twisted together and braided, instead of just the cables.

Double braided cables have an internal braided core that is then covered by an outer braided sheath. The benefit is that this type of anchor cable is extremely strong. However, the time taken to manufacture the cable can be labour intensive.

Natural fibres such as hemp and jute are rapidly being replaced with synthetic fibres that are considerably stronger. Polyamides are a common material for cables, and a well-known variety is Nylon. It has a high resistance to damage from exposure to UV from sunlight and has a near 30% elasticity that makes it suitable to absorb and dissipate forces.

A replacement for nylon cables is polyester, known by its commercial name Dacron. These nearly possess the same strength as Nylon but are not as elastic. To overcome this lack of dampening, a longer rode can be paid out.

Polyester is better than Nylon when it comes to retaining its length and overall shape when it is exposed to water. In addition, it has better resistance to damage from UV exposure and abrasion.

A slightly less common alternative is polypropylene, which is preferred since it floats in water. However, it is not as strong and is extremely sensitive to UV exposure. A common replacement for the standard synthetic rodes is the combination of reinforced polymer braided with conventional nylon or Dacron.

By doing this, the strength to weight ratio of the rode becomes considerably large, while keeping the overall length and scope the same. These reinforced anchor cables are common in offshore installations and are used by tug boats to pull various structures in ports.

Anchor Chain

The anchor chain is made up of multiple link segments that resemble closed loops. Each loop is connected through to its neighbouring loops, creating a chain of any given length.

The major advantage with this type of anchor rode is that it is resistant to the wear and tear that is extremely common with anchor cables. Because it is generally made of metal, the rubbing action between two adjacent links will cause only small deformations over long periods.

Compared to the problem of chaffing with cables, the chain rode can withstand almost all types of friction-related deformations with the application of lubricants. Most lubricants eventually come off as a result of continuous exposure to water. However, this merely requires the anchor to be wound back up, and the required links to be coated in grease.

Although common lubricants such as WD-40 are used, their toxic effects on the marine flora and fauna because of chemical exposure have gradually resulted in them being switched out for grease and other types of lubricants.

Another advantage with the anchor chain is that it can compactly fit in the anchor chain storage locker, because of the individual weight of each link. Unlike rope or cable that tends to be elastic, and hence more difficult to coil up, the individual links are much easier to store.

However, the biggest problem with using chains, especially for large structures such as ships or offshore installations, is that the anchor rode becomes extremely heavy. When this is combined with the weight of the anchor itself, the total mass of the system comes to a few tons. To be able to haul up this weight, heavy-duty motors or cranes are required, that can complicate the operation.

Another issue is that metal does not absorb as much energy compared to cable or ropes. Because of this, it is often not able to redirect any jerks or other disturbances being generated from the ocean bed or seafloor. If the entire chain abruptly becomes taut because of natural wave motions, a massive shock can be transmitted to the vessel or structure, that can cause failure and metal fatigue over time.

An interesting aspect of anchor chains is the catenary action of weighted links. Since each link weighs a sizeable amount, the entire chain tends to sag or fall in the middle because of this weight. Catenary refers to the natural shape that a chain takes when it is suspended between two points.

The benefit of this catenary action is that it decreases the initial angle between the seafloor or ocean bed and the anchor rode. Because of this, a certain amount of forces and loads are absorbed and dissipated away from the structure and anchor. However, this only takes place as long as the angle remains small and there are acceptable ranges of loads.

This type of anchor rode is mainly used for large vessels and offshore installations. This is because these structures are considerably heavy, displacing several tens of thousands of cubic metres of water. If a cable rode is used to anchor these structures, it will eventually chaff and simply break apart.

Heavy-duty metal chain links are used that can withstand the enormous loads placed on the chain. Common materials that are used in manufacturing the individual metal links include high carbon steel and heat-treated high carbon steel. The latter is known as the transport chain or G70 and has an exceptional strength to weight ratio that makes it ideal for such purposes.

Combination of Cable and Chain Anchor

Considering the various parameters involved in the pure chain and rope designs, a combination of both types of anchor rodes would be able to eliminate certain disadvantages.

This is used in large offshore structures and large cruisers. The combination works on the principle that the chain portion of the anchor rode would be present in areas where abrasion of conventional cables is likely to occur. This would ensure that the overall integrity of the structure remains intact, while not affecting the dampening effect of the rode.

Thus, the chain portion is attached directly to the anchor stock, while the cable forms the rest of the rode. In general, the junction between the chain and cable is the weakest portion in the rode, and specialized methods of joining both types of rodes must be used.

A galvanized connection is used to cover the junction, and the cable fibres are partially connected to the chain. Along with this, the cable can be spliced directly into the chain.

Another advantage in using a cable-chain combination is that the angle between the bed and anchor rode decreases, which in turn decreases the vertical loading on the floating structure. However, it only works in moderate to light underwater currents. Otherwise, the chain is not heavy enough to remain on the ocean bed.

The solution is to pay out a longer rode that will aid in dissipating a certain amount of energy away from the anchor. The risk of drifting increases with a proportional increase in the rode length, and it is advisable to optimize the length of anchor rode paid out based on these parameters.

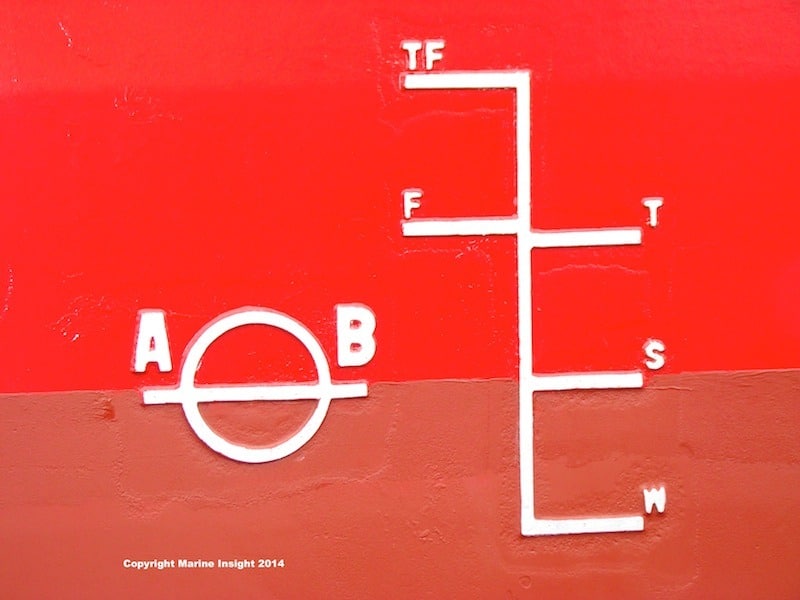

Anchor Chain Marking

The scope of the anchor rode plays an important role in balancing the amount of drift and forces borne by the chain or cable during anchoring operations. Thus, it is important to have an accurate value of the length of the anchor rode paid out. To measure this, specialized markings are present on the anchor rode, so that the length paid out can be visually identified by the anchor operator and other personnel.

The most common methods of marking the anchor rode are- plastic marker elements or painted sections.

Plastic elements such as zip-ties and blocks are fairly common owing to the ease of setting up and replacing these components once they wear off.

In addition, since they are made of plastic, they have a higher life on the seas compared to paint and other methods. Coloured zip ties are knotted at regular intervals (the standard is 25 feet or slightly more than 7.5 meters) and they indicate the length that has already been paid out.

Colour codes indicate the length and are generally composed of white, red and blue based on maritime standards. However, the issue with plastic components is that they can get caught in the windlass and other anchoring equipment.

Moreover, they can break apart if continuously rubbed on the hawsepipe and tethering spool. The broken plastic portions can end up polluting the waters and pose a grave environmental hazard that cannot be overlooked.

Paint is another fairly common method of marking anchor chains. This follows a three-colour system, similar to the plastic tie method. Each of these colours indicates a specific digit and a significant number of the length of the anchor rode.

The functioning is similar to the markings of resistor bands on electric equipment. Each of the three bands in a certain order can represent a unique number, based on the determined marker differences.

For instance, a certain ship operator decides that the difference between two adjacent painted marks on the anchor rode is to be 25 feet. Then, a certain order of the three bands will indicate a unique multiple of 25, that can be used to identify the length of the rode paid out.

Painting these bands is a common approach, especially since environment-friendly paints are easily available on the market. However, the only issue with this method is that the paint can wear off rather rapidly owing to the harsh climates it is exposed to. To combat this wear and tear, frequent coats must be applied, and the bands must be made wide enough so that even if the paint flakes off, there is still a sizeable portion left to correctly identify the anchor rode length with.

Anchor Chain Stowage Arrangement

From the previous discussion, it is evident that the anchor chain plays a vital role in conjunction with the anchor. However, since modern anchors are made from metal or from a rope, they stand a high chance of wear and tear related issues, such as rusting or chaffing.

The solution is to constantly monitor the anchor rode whenever it is hauled back on to the vessel.

For this, special stowage arrangements have to be made such that the rode is kept safely away from corrosive substances and so that it can be easily accessed for either maintenance or to paid out with the anchor.

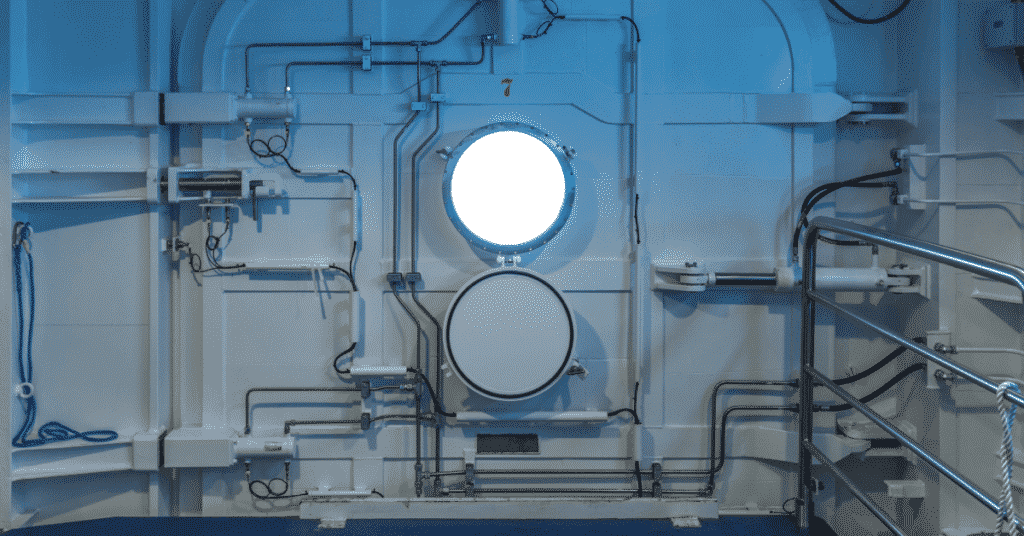

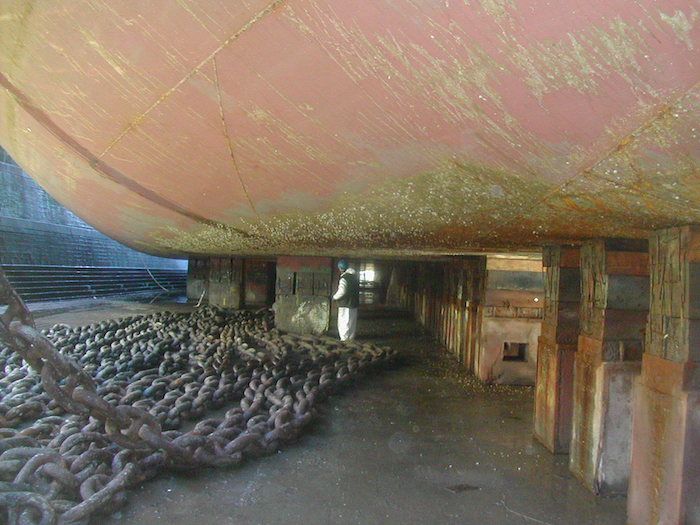

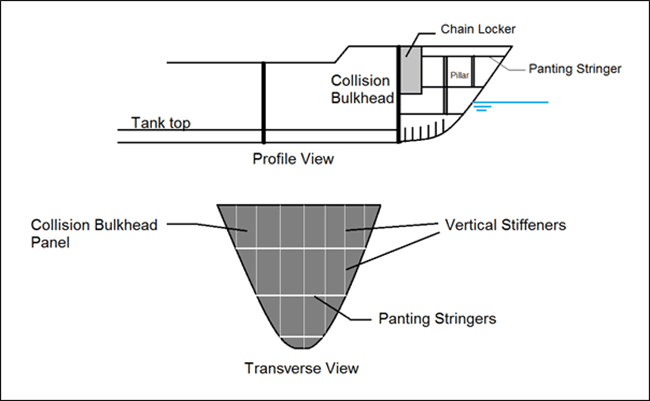

Anchor chains are stored in a chain locker set deep within the hull of the vessel. These are ventilated enclosures that are used to store the anchor while it is not in use, and to house the remaining length of the anchor chain while it is deployed. It can be accessed by engineers and personnel for routine checks or long-term maintenance.

Generally, the floor of the chain locker is reinforced, so that it can bear the extra weight of the metal rode. To haul the chain out of the locker, a series of heavy-duty motors and gears are set up on the deck in pairs.

The reason for the pairing of the anchor stowage equipment is so that there are individual components for the port and starboard side anchors. In the event of mechanical failure, if both anchor lines were operated by the same windlass, it could leave the vessel prone to drifting. The windlass is the technical term used to define the motor that lowers or lifts the anchor chain.

Along with the windlass, a secondary spool is present in front of it, on the deck. The purpose behind this is to ensure that the individual links do not get entangled while being moved. It straightens the chain and slowly feeds it out of the vessel. There is a locking mechanism present on this spool so that the chain can be fixed at the desired length once it is deployed.

Lastly, the hawsepipe or cat’s hole is the gap in the hull through which the anchor rode is paid out. It serves three main purposes- to feed the anchor chain, to house cleaning equipment for the rode, and to hold the anchor head in place. As defined, the hawsepipe allows an outlet on the port and starboard sides for the chain to be lowered or lifted into the chain locker.

Moreover, when the chain is hauled out of the water, there is a high chance that it may be littered with subsurface gravel, mud and even living organisms. To get rid of this organic matter, hoses are fitted along the mouth of the hawsepipe, so that the rode can be cleaned before storage.

Finally, the anchor is firmly held on to the side of the hull by the locking mechanism provided on the hawsepipe. It also restricts the movement of the anchor head, which would otherwise cause damage if left unattended, especially during storms.

Anchor rodes play an important role in securing the anchor to the vessel or structure. Without the right choice of type and materials, there can be serious consequences for the structural integrity of the anchor system. Based on the type of linking, anchor rodes can be broadly classified into cable and chain types.

Cables are preferred for lightweight and small boats, whereas chains are common for larger structures such as ships and offshore rigs. Modern anchor rodes combine both these types to improve durability, dampening effects and overall strength of the anchor.

The scope is a measure of the ratio of the length of anchor paid out and the depth of the waterbody. By choosing the right type of anchor rode based on the vessel size and overall operating conditions, and by opting for the right materials to manufacture the rode with, the life of the anchor system can be increased.

Do you have info to share with us ? Suggest a correction

About Author

Ajay Menon is a graduate of the Indian Institute of Technology, Kharagpur, with an integrated major in Ocean Engineering and Naval Architecture. Besides writing, he balances chess and works out tunes on his keyboard during his free time.

Latest Marine Navigation Articles You Would Like:

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.