Controllable Pitch Propeller (CPP) Vs Fixed Pitch Propeller (FPP)

Most of the propellers that are used in ships are fixed pitch propellers (FPP). What does this propeller term mean? Let’s understand this from a beginner’s point of view.

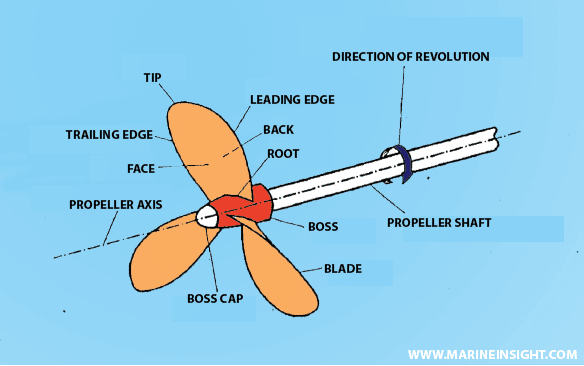

If you look at a propeller axially, you will notice a twist in the propeller blade along the length of the propeller hub. It is this twist in the blade that results in the forward motion of the propeller with each rotation.

It is pretty much what you see on a screw. The angle of the thread is actually what is called the pitch angle.

The more the pitch angle, the more distance is travelled by the screw in one rotation, that is, the more is the pitch.

Similarly, propellers act on the principle of a screw. Hence the term screw propeller.

But what is a fixed pitch propeller or the FPP?

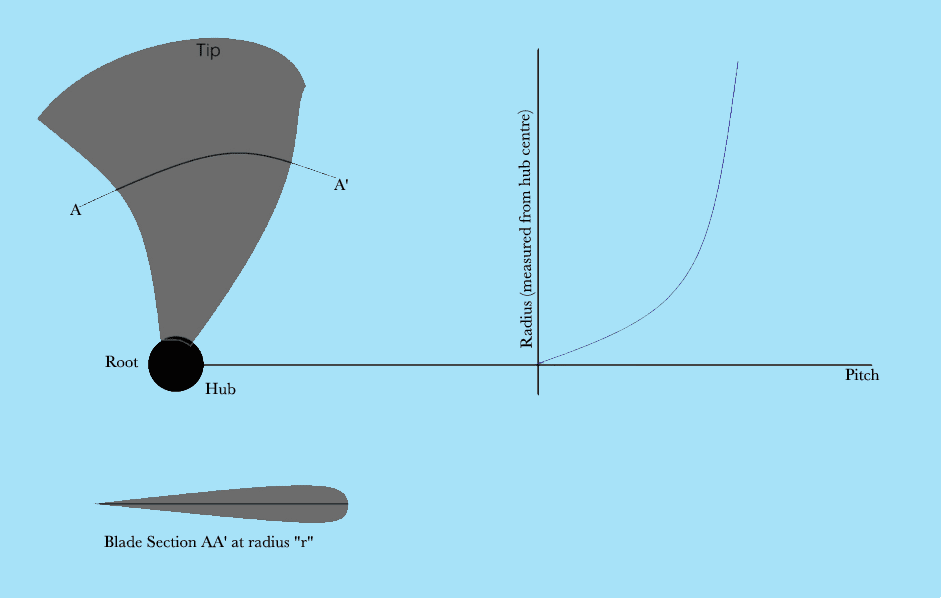

The propeller is designed in a way such that, if you cut the propeller radially at any random radius from its centre, then the cut section of the propeller blades will have a certain pitch (magnitude depends upon how twisted it is along the length of the hub).

Now if you rotate this cut section in water, the axial distance travelled in one rotation is the pitch of this section. If you vary the radius at which you cut a section, the twist of the blade also varies from the root to the tip. This makes it evident that each section of the propeller has a particular pitch.

The root of the propeller will have a different pitch from the tip of the propeller. So the pitch variation from the root to the tip is as shown in Figure 1.

The question now is, if each section has a different pitch, then what is the resultant pitch of the propeller? The answer is the resultant pitch is the average of all the pitches of each section of the propeller.

Note very carefully, that the pitch varies along with the blade section (or increasing distance from the propeller centre), but the net average or the net pitch of the propeller remains constant. Such a propeller is a fixed-pitch propeller.

Now, let’s go back to the concept of a screw. What if you could somehow change the angle of inclination of the threads along the screw?

If you could, what would you actually be doing is changing the pitch angle and subsequently, the pitch of the screw. This is exactly why the controllable pitch propeller was developed by the industry.

We will be dealing with the applications in detail a little later. But for now, it is vital to know the fundamental working of a Controllable Pitch Propeller (CPP) also commonly known as Variable Pitch Propeller.

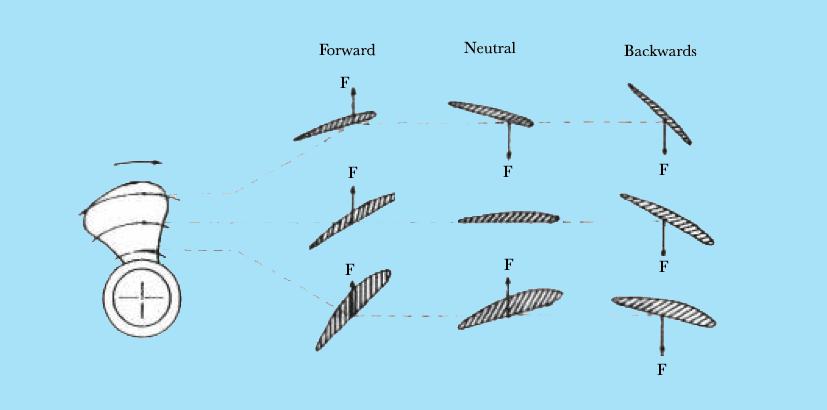

The twist (to be referred to as pitch from now on) of the root section of the blade is always with respect to the angle it makes with the propeller hub. What if we can change the angle of orientation of the root?

And since all the other blade sections had their previous pitch angle already, they attain a new pitch angle.

In other words, you are able to control the pitch of the entire propeller, by changing the orientation of the root section on the hub. This is done by the means of a hydraulic cylinder.

When the required orientation or pitch of the propeller is obtained, the blades are locked in that position.

So the blades are not an integral part of (or not casted along with) the propeller hub. They are mounted on spindles that have axes perpendicular to the shaft axis.

Advantages and Disadvantages of CPP and FPP

The following points will discuss the applications and their relations with the advantages and disadvantages of CPP and FPP systems:

- The controllable pitch propellers can be used to run the ship in forward and astern direction both, without the requirement to change the direction of rotation of the engine. How? Well, the propeller works on the principle of lift generated by each aerofoil section of the blade. What if we can change the orientation of the blade, such that the direction of life force is opposite to what it was during forward running of the ship? That’s exactly what is achieved by changing the pitch angle of the blades, as shown in Figure 2.

- A non-reversible engine can be used for both forward and astern operation of the ship. Hence, the weight of the engine and propulsion machinery is reduced considerably when compared to what is required in propulsion systems equipped with fixed pitch propellers.

- Since the pitch of the propeller determines the amount of thrust generated by the propeller, a change in the pitch angle can bring about a change in the speed of the ship. So, a controllable pitch propeller is useful in changing the speed of the ship without changing the speed or rpm of the main engine. But why are we focusing on this advantage? What happens if we need to reduce the engine rpm to reduce the ship’s speed? Well, many ships have a shaft driven diesel alternator system. So the rpm of the main engine shaft controls the electric power production on board. In that case, if the speed was to be reduced using a fixed-pitch propeller, it would require a reduction in the shaft rpm, which would result in a reduction of power generated.

- Due to the above reason, the speed of the ship can be handled from the navigation bridge directly. In case of fixed pitch propellers, the marine engineer needs to be intimidated in order to change the ship’s speed. Therefore CPP technology is used for obtaining a faster response of speed change.

- The efficiency of an astern condition in case of fixed pitch propellers is less than that of controllable pitch propeller in astern condition.

However, there are many disadvantages of using a controllable pitch propeller to a fixed-pitch propeller. It is important to know them too.

- The pitch control mechanism installed in the hub is complicated enough to demand proper inspection at regular intervals. The installation process is also more complicated as compared to that of fixed-pitch propeller system.

- Controllable pitch propellers have a very high initial cost. And this cost increases rapidly with increasing diameter of the propeller.

- Due to pitch control mechanisms housed inside the hub, the length and the diameter of the hub is also high as compared to the fixed-pitch propeller systems.

To conclude, it is vital to know the applications of controllable pitch propellers. These are used in ships that are required to operate at variable speeds even when operating at constant power requirements. Such ships are tugs, trawlers, ferries, ice breakers, and small scale warships that are equipped with gas turbines.

Over to you..

What according to you are the most important features of CPP and FPP?

Let’s know in the comments below.

You might also like to read:

- Marine Propeller Shaft: Design And Construction

- Understanding Propeller Hubs: Design, Functioning, and Maintenance

- Propeller, Types of Propellers and Construction of Propellers

- Understanding Design Of Ship Propeller

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

been a deck cadet for about 18 months now …..sailed on both type of propulsion system ….. CPP .it’s the best for manoeuvring …. being on bridge when entering port or channel …. when the pilot sees a CPP ….You can see the grin on his face … reduces tension on the bridge a lot

1.What are the advantages and disadvantages of fixed propeller in ship?

2.what are the advantages and disadvantages of controllable pitch properller?

Can we use the azipod in a merchant ship instead of cpp or fpp?

Very interesting article!

I also think that CPPs have better performance against cavitation, as they tend to adjust their operation (P/D) through speed changes.

However, CPPs are more expensive and require a complicated control system (automated ?).

And there is a lot of study on how to choose a CPP as well as regulating the expected changes in pitch ratio through speed changes.

Moreover, CPPs, as far as I consider, are ideal for hybrid vessels, that use Prime Movers in combination with Electric Motors/Shaft Generators etc.

Not necessarily: (@ Antonis

C) I sailed for 11 years now, served on a few ships, two of which were old as fuck and yet they were cpp. m.v suilven made in 1973 with original cpp from construction. And m.v queen of prince Rupert..

Even older still 1954

.and cpp also

So u see cpp been in the industry long before u been in the world. If u don’t believe me google that shit..who and when they invented cpp. U b amazed it’s old teck

The reason I prefer a CP propellor is versatility in use while maintaining the engine at peak fuel/load efficiency. AHTS’s are where they really shine where you can put full torque and horsepower to the water regardless of the speed over the ground, and minimize cavitation and slippage in the process.

The CPP is ussing for the ships with special manuvering – tugs, fishing bouts or cargo vessels like small RO-RO or container vessels, the FPP is ussing for long voyage vessels – ocean going vessels.

Good article

Which propeller, FPP or CPP is more suitable to use with Dual Fuel Engine? And Why?

Theortical speed calculation for controllable pitch propeller

Based on my personal experience with a CPP propulsion, where the CPP is engaged or clutched in with the main engine, what happens if there is need to reduce the main engine rpm in an emergency to save the main from an incident of overheating owing to a sudden trip off from the main engine fresh water jacket cooling pump, where the CPP has to be clutched out or disengaged from the main engine before reducing the rpm of the main engine. I was lucky to have switched on the fresh water jacket cooling pump to reduced and restore to normal the sudden rise in the jacket fresh cooling water having informed the deck officer on watch to reduce speed of CPP to enable disengagement or clutch out of CPP.

CPP has replaced the need for a direct reversible main engine for manoeuvring purpose saving time, saving fuel and cost of maintenance. It is still the best.

In my experiences: whilst ship is going astern with rudder in midship position, bow swing to starboard side with FPP; and bow swing to port side with CPP.

I have problem with system of pitch controller propler in vibration when i raise the speed the vibration raise and vibrate the whole ship what should i do ???

how about the comparison of fuel consumption fror FPP against CPP?

CPP is more fuel economical as compare to FPP

CPP does not give room for reduced fuel consumption at part load/ low speed as the engine continue a constant speed

Good article, but, guys, I am just reading the book “Shiphandling for the Mariner” written by Captains Daniel E. MacElrevey and Daniel H. MacElrevey where, on the page 52, is written that

“A variable pitch propeller going astern is less effective than a conventional propeller.”

which is pretty much in conflict with the statement from this article that

“The efficiency of astern condition in case of fixed pitch propellers is less than that of controllable pitch propeller in astern condition.”

Regards

We allways use CPP in our Lean Propulsion solutions, for any type of ships.

May ship owner regrets going FP, very few regrets a CPP .

It is important to see the whole propusion chain, what is the better.

twin propeller FPP is always out turning?? is it true? and why?