Introduction to Anchor Design

Anchors are as old as the ships and boats themselves. But have you wondered how they work and what accounts for the typicality in their form and design?

As we know, the seas are highly variable environments constantly subject to the whims of the environment. Hence, for any kind of marine vessel, whenever there is a need to temporarily station or halt them amid the sea or anywhere near the coast, anchors have proven to be the most reliable means since time beginning.

In simple terms, an anchor can be compared to a parking brake in an automobile which is used to position or dock a vessel in the desired location for a certain amount of time so that it does not drift or veer away due to the various environmental forces like winds, waves, or currents, common in an ocean environment.

So, an anchor is a simple mechanical device, which secures a floating vessel at a particular location and prevents it from drifting away from that particular point by lodging or partially burying itself into the holding ground, which is the bottom seabed or seafloor in this case. The necessary amount of grip from the anchor is created by the virtue of its own weight and the extent to which it has settled into the ground below.

In modern times, several vessels are equipped with advanced technologies such as azimuth bow thrusters or Dynamic Positioning System (DPS), which are automated and fully mechanized systems for stationing the vessel anywhere and irrespective of conditions.

However, even for such vessels, anchors are still present as contingency measures for anchorage in case of failures of such modern systems and hence, one can never deny their importance.

Parts of Anchor System

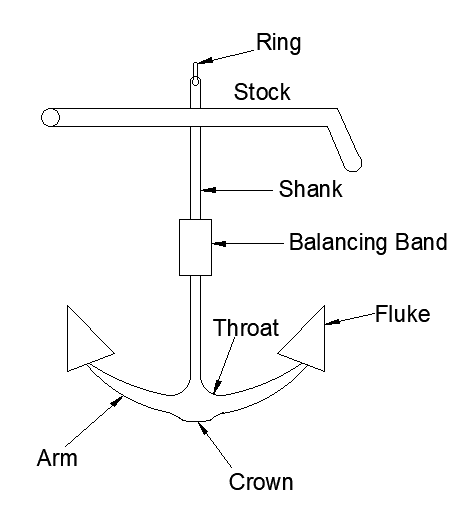

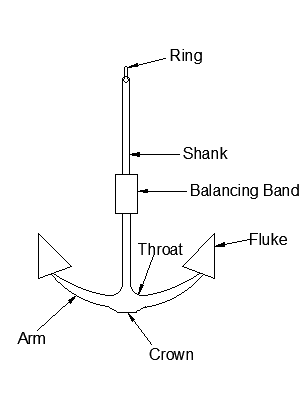

Though there are several types of anchors used, which differ in appearance and form, the fundamental parts of an anchor system can be generalized as:

Ring or hook: This serves as the point of attachment of the anchor to the anchor chain or cable. It is generally located at the uppermost point of the anchor.

Shank: It is the central, axial and vertical long part of the anchor running from the ring to the lower part of the arms. This part comprises a large amount of weight and this helps in better entombing of the anchor to the seabed or floor while the vessel is intended to be positioned.

Crown: The lowermost rounded, arc-shaped section of the anchor rests in the seabed and connects the arms to the central shaft. This extends in both sides, forming the arms. The shank is directly fitted to the crown and often forms a ball-and-socket joint capable of making a 30 or 45-degree rotation.

Arms: The lower projections of the anchor extend in either direction from the crown and contributes significantly to the grip. For better grasp, curved arms became increasingly popular since the early 19th century and hence, straight arms seldom exist.

Fluke: This is the flat shield-like part that constitutes the tip end of the arms extending in both directions and plays a very important role in fastening themselves to the seafloor by digging or clinging to the bottom mud or rocky elements. Flukes are sharp in nature for better penetration. Most modern anchors are characteristic of fluke which may be of different efficient shapes, and such anchor types are known as fluked anchors (see below).

Throat: The curved inner extension of the arm where it joins the shank.

Balancing Band: It is a sleeve-like structure fitted near the centre of the shank such that the anchor balances itself horizontally during lifting operations.

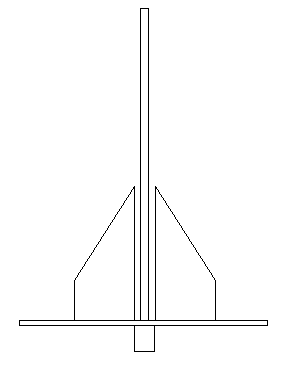

Stock: The stock was chiefly used in older designs like the Admiralty type anchors since their advent in the 17th and 18th centuries. These are also known as stocked anchors. The stock is basically like a shaft that passes through the topmost point of the shank in a perpendicular direction to the arms and acts as a screw that turns itself so that one of the arms and flukes digs itself properly into the seabed. However, one major difficulty faced by stocked anchors is their difficulty to bestow. Thus, most modern designs are stockless.

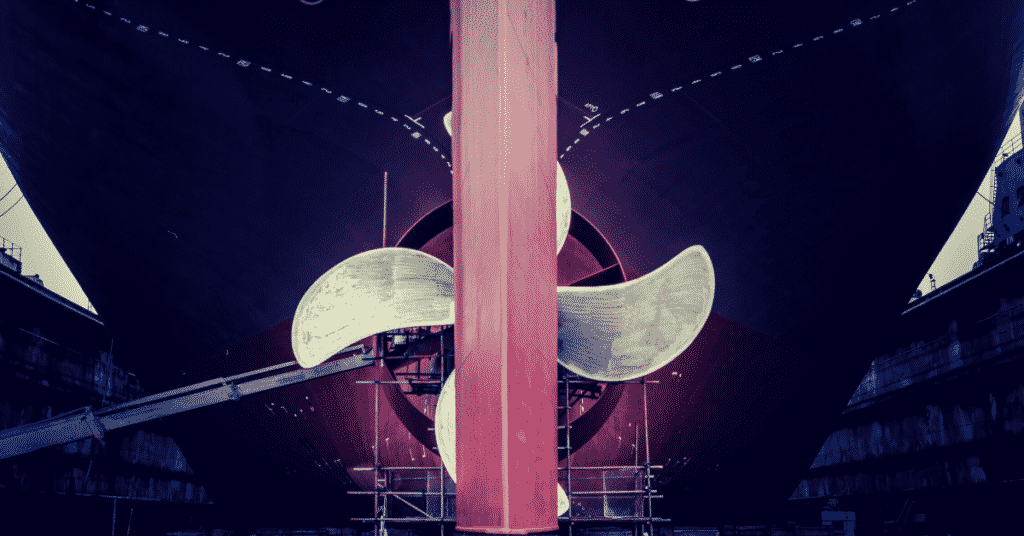

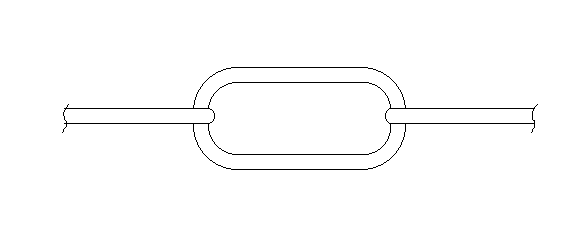

Chain cable: The function of a chain cable is lowering and hauling back the anchor to and from the seabed based on the requirement as well as maintaining mechanical stability when the vessel is desired to be anchored at a particular location. The chain cable of an anchor comprises studded or interlocked steel links over its entire length also known as shackles. The studs or shackles are reinforced by a locking pin. The entire chain cable arrangement is considerably heavy and thus while anchorage, their self-weights also contribute significantly to the positioning of the vessel along with, of course, the principal component of tension.

Hawse pipe: This helps in guiding the chain cable arrangement from the deck level to the outside of the shell plating while lowering or hauling up the anchor. The boring of this pipe should be sufficient enough for the smooth and unhindered function of the chain cable without any chance of obstruction, clogging or damage.

Chain stopper: The chain stopper acts as intermediate support and guides for the chain between the windlass and the hawse pipe. Thus, while pulling or lowering the chain cable, the stopper helps in directing the arrangement properly to or from the hawse pipe. The stoppers are of considerable strength and are designed to withstand and absorb both the weight as well as the high tensile loads from the chain during operation. Commonly, chain stoppers have a roller-like arrangement for guiding the cable arrangement and lessen frictional loads to be counteracted by the windlass.

Chain Locker and Anchor Pocket: When not in use, the entire chain cable is stored in a particular enclosure underneath the main deck plating known as the chain locker. The chain, in turn, is connected to the windlass with a pipe connection known as the Spurling Pipe. The chain locker has airing holes to help drainage in case of flooding.

In the same way, the main anchor is stowed at a particular recess in the side shell plating known as the anchor pocket. The shank and the rest of the upper part of the anchor remain inside and only the fluke and the lower arms are visible when viewed from the ship’s side. The anchor point is placed well above the draft line to avoid chances of water ingress.

Windlass: This is the most important component of the anchor arrangement used for lowering and pulling up the entire system as and when required. The physics of a windlass is a simple mechanical pulley system for lifting loads in the vertical direction. In early vessels, the windlass was operated by human effort and that was soon followed by mechanized systems driven by electrical or hydraulic power.

The basic design of a windlass includes a cable wheel or a barrel rotating about a central axis which is the pulley and is wound by the chain cable. There is a gearbox and a motor connecting this with another winch or drum which is rotated by mechanical or electrical means and acts as a driver for controlling the motions of the chain cable.

Windlass is often used interchangeably with capstan, which is similar in operation and purpose, the only difference being the vertical orientation of the winch which rotates about its vertical axis. For capstans or vertical winches, the rest of the machinery is located below the deck plating, unlike the horizontal windlasses. For a more detailed review of anchor windlasses, refer to this article.

A Summary On Types of Anchors

Anchors have undergone a considerable amount of evolution in tandem with the vessels themselves- from sandbags, stones, and wooden logs or blocks used in the ancient era to the metallic ones which have continued to be used till the recent times. Over generations, the anchors composed of metals have also evolved to a significant degree with several designs. However, as aforesaid, the most widely used anchors for all practical purposes have more or less the same parts and can be classified into the types:

- Fluked anchors

- Admiralty or stocked anchors

- Stockless anchors

It can be well-argued that fluked anchors have been the most used ones and have encompassed both stocked and stockless anchors since the efficiency of the flukes in the better entrenchment of the anchors to the seabed have proved to be peerless.

Stocked anchors and stockless anchors are also quite similar in design apart from the only major difference which is the stock structure fitted at the top of the shank. Though due to the problems in stowage because of the stock, stocked anchors have been gradually phased out, they are continued to be used in river vessels. The stockless anchor is the most popular form of temporary anchor used in the present day.

This design was patented in 1821 and is the most preferred form of anchorage in large vessels. Apart from the ease in construction, storage and handling, another major improvement in stockless anchors is the presence of two pivotable flukes perpendicular to the shank for better grip. Furthermore, it can be lowered into the water much faster than any other type of anchor.

However, the stockless anchor is not very efficient in softer, more cohesive, silty surfaces. This is one of the most important reasons, this is not very preferred for riverine or other shallow-draft vessels and its older counterparts including the stocked anchors are preferred instead.

Speaking of smaller or shallow-draft vessels, some typical designs have existed for a considerable amount of time along with different versions of the classic Admiralty/Stock anchors.

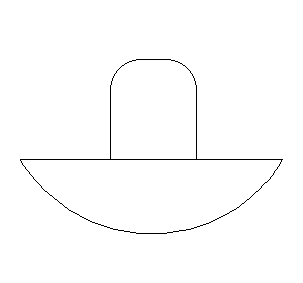

Mushroom Anchor: This is one of the simplest forms of anchors. It is nothing but an inverted mushroom-shaped, bulbous weight that gets buried on the floor and restricts the free movement of the vessel simply by the virtue of its own weight and holding capacity. Since softer surfaces like silty beds, get almost permanently buried inside the layers, they are often very difficult to retrieve. It is highly preferred for soft riverbeds and is often deployed by personal crafts or fishing vessels. They do not offer much protection and grip in inclement weather conditions and harder surfaces.

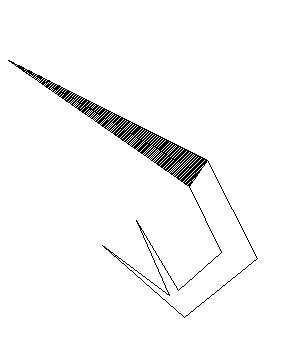

Danforth Anchors: They are also known as fluke anchors but should not be confused with fluked anchors which are traditional large anchors with flukes as explained above. These anchors have a hinged stock mounted atop the crown to which two prominent triangular flukes are attached. These flukes dig deep into the muddy bottom and offer a high degree of resistance to external disturbances. These types of anchors are compact and easier to stow Thus does not offer much effectiveness in harder or grasses surfaces

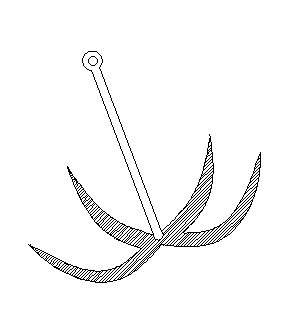

Grapnel Anchor: These are some of the oldest types of anchors. This has a vertical shank and is hemmed by four or more protruding arms also known as tines. These tines simply act as hooks and cling to any uneven surface it encounters. These tines are often bendable for making retrieval easier. They are small and lightweight in size.

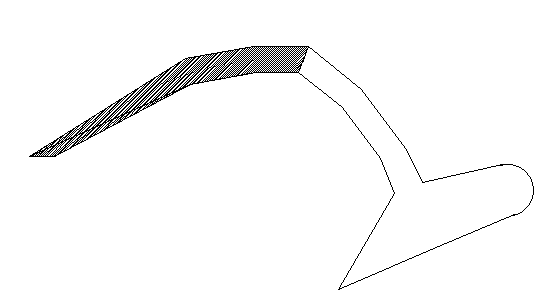

Plough Anchor: The name plough derives from its resemblance to an agricultural plough with a spade-like structure in front of the rod or shank. It simple digs or ploughs into the surface and while retrieval break away from its position. They are deemed suitable for all kinds of surfaces including both soft and hard but do not offer a very high degree of efficacy when it comes to larger vessels or greater environmental forces.

Delta Anchor: The delta anchor is very much similar to the plough anchor but has a much larger fluke area. These are mainly used for some offshore structures like oil rigs.

Claw Anchor: As the name suggests, the frontal or part of this anchor is shaped like a claw or a scoop that grasps onto the surface in a way similar to an excavating machine. Though they had been conceived for smaller vessels, they were also found to be equally suitable for larger vessels and offshore structures. However, for better efficacy, the size of such anchors needs to be proportionately largened in tandem to the vessel size and coupled with bulk shape and rigidity, these could be cumbersome to stow and handle. Moreover, they are not good for hard-bottom surfaces.

You might also like to read:

- What Are Let Go and & Walk Back Ship Anchoring Methods?

- A Guide To Types Of Anchors

- What is Anchor Chain: Everything You Should Know

- 9 Points to Remember When Dropping Ship Anchor in Emergency

- Responsibilities Of Deck Officer During Anchoring Operation

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

Do you have info to share with us ? Suggest a correction

About Author

Subhodeep is a Naval Architecture and Ocean Engineering graduate. Interested in the intricacies of marine structures and goal-based design aspects, he is dedicated to sharing and propagation of common technical knowledge within this sector, which, at this very moment, requires a turnabout to flourish back to its old glory.

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.