Procedure for Starting and Stopping of Sewage Treatment Plant on a Ship

Any machine on the ship requires a proper procedure to be followed for starting and stopping it. Failure to follow this step-by-step procedure will lead to either failure in starting or stopping the machine or lead to some fault.

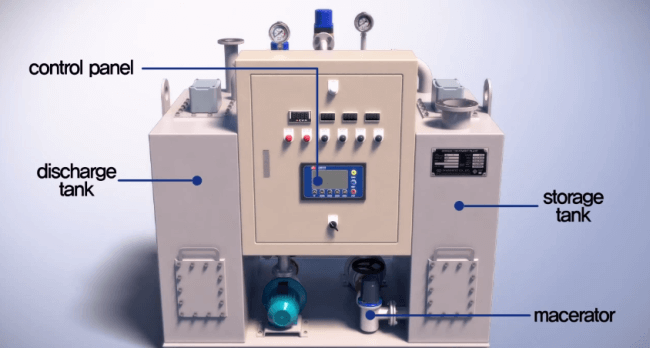

Sewage treatment plant is one such equipment on the ship which requires a step-by-step procedure to be followed for starting and stopping it. In this article we will go through the procedure of starting and stopping a sewage treatment plant.

Starting of a Sewage Plant

Sewage plant is generally running all the time during sailing, but it might need to be started when the ship is installed with a new sewage treat plant which needs to be stopped at regular interval of time for improving its performance and maintenance procedures. Below are the points that need to be followed for starting a sewage treatment plant.

1. Make sure if any maintenance is carried out on the sewage treatment system, all the openings have been closed properly before starting.

2. The sewage plant is be filled with fresh water inside the chamber.

3. At this stage, there are no aerobic bacteria inside the chamber, but the sewage has started coming to the plant. Thus, in order to increase efficiency and starting rate of the plant bio pac is added to the plant by flushing the amount specified in the manual. This bio pac is mixed with warm water which helps in growth of these bacteria and also efficient functioning of the plant.

4. If the bio pac is not added, the plant might take up to 5 to 7 days to be completely functional. However, with the bio pac it becomes functional within 24 hours.

5. Start the air compressor or open the air valve as per the design of the plant. The pressure is maintained as per the manual. Generally 0.3-0.4 bars.

6. Open the sewage overboard valve and close holding tank valve when the ship is out of restricted waters.

7. The plant is continuously monitored and checked for the flow through the transparent plastic tubes.

8. The sample is taken for checking for suspended solids and chlorine content.

Stopping of the plant

Stopping of the sewage treatment plant is generally done either before entering the dry dock or in case some maintenance has to be carried out inside the treatment plant.

1. For stopping the system, close the inlet valve to the sewage plant and close the overboard valve and let the sewage go overboard.

2. Empty all the three chambers of the plant i.e. aeration, settling and chlorination chambers. If the chambers are not emptied, it will lead to growth of anaerobic bacteria which forms the toxic H2S gas.

3. If entry has to be made inside the tank, the later should be checked for hydrogen sulphide gas H2S with the help of dragor tube by taking a continuous sample from the plant. Entry is made with the help of mask and rubber gloves should be put on.

4. In case the ship is going to dry dock the overboard should be connected to shore reception facilities.

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Plz explain the first point in stopping is it close the overboard valve or open the obd valve

Can you please add the parts? Major and Minor Parts? Thank you!

so much information is shared in this article. th

Sewage treatment “infrastructure” is built at the level of cities and towns, it is now becoming common to find STPs at community levels – i.e., at apartment, business campus, schools or institutional campus scales. If planned well, sewage treatment systems can be designed and implemented at the individual household level.

We are committed to our clients for providing compact design and features like durability, low maintenance, corrosion resistance and longer service life. Our solutions are both standard and customized as per need of our clients. please contact us we will revert back as as possible