A Guide To Marine Elevators: Construction, Safety Devices & Maintenance

Marine elevators are specially designed elevators to withstand all ship-board conditions such as adverse weather, humidity, rolling, pitching, etc. With a loading capacity of 500 to 800 kgs and passenger capacity of 5-6 person, the elevator runs with the help of AC440V 60hz motor driving a single wrap traction geared type driving system. Also, there is AC 2 step speed with selective collective control and push-button operation system. There are no specific regulations for elevator maintenance, however, SOLAS Convention chapter l, part B (Surveys and certificates) requires that all equipment fitted onboard ship should be in satisfactory conditions and fit for the service for which it is intended, which also include elevators.

There have been few fatal accidents on cargo ships in past involving elevator which made the authorities to make more stringent rules for efficient operation and maintenance. Now, all classification societies and flag states require a company/owners to include ship elevator maintenance in the Shipboard Maintenance Plan (SMS).

Construction And Operation Of Marine Elevators

Let us understand the construction, safety and functioning of a standard marine elevators

Construction:

1) Cage

The marine elevator frame is made of stainless steel with reinforcing material to withstand the rated load. Steel plate of sufficient thickness and a vinyl sheet is provided for the floor. The side walls are provided with steel plate of comparatively less thickness and are such constructed that there is no possibility of touching the wall of the elevator trunk, counterbalance and other switches from inside of the cage. The cage door is a sliding type door made of steel and is provided on each level. The operating board and handrail are provided in the cage. The fluorescent lamp and emergency lamp are fitted in the ceiling.

2) Counterweight

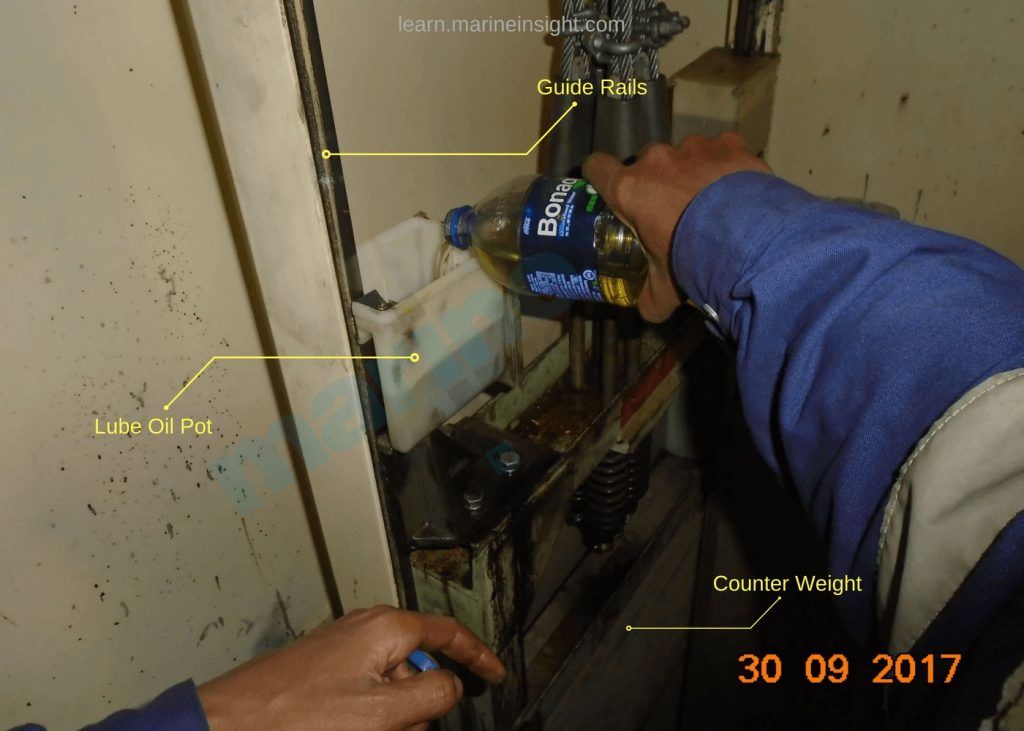

This consists of the frame of shape steels and cast-iron pieces that are bundled with bolts. T-type rail for the elevator is adopted as a guide for both cage and counterweight.

3) Wire Rope

A rope made of mild steel is provided for the elevator and the safety ratio is designed to have more than 10. They are 4 in number with roping 1:1

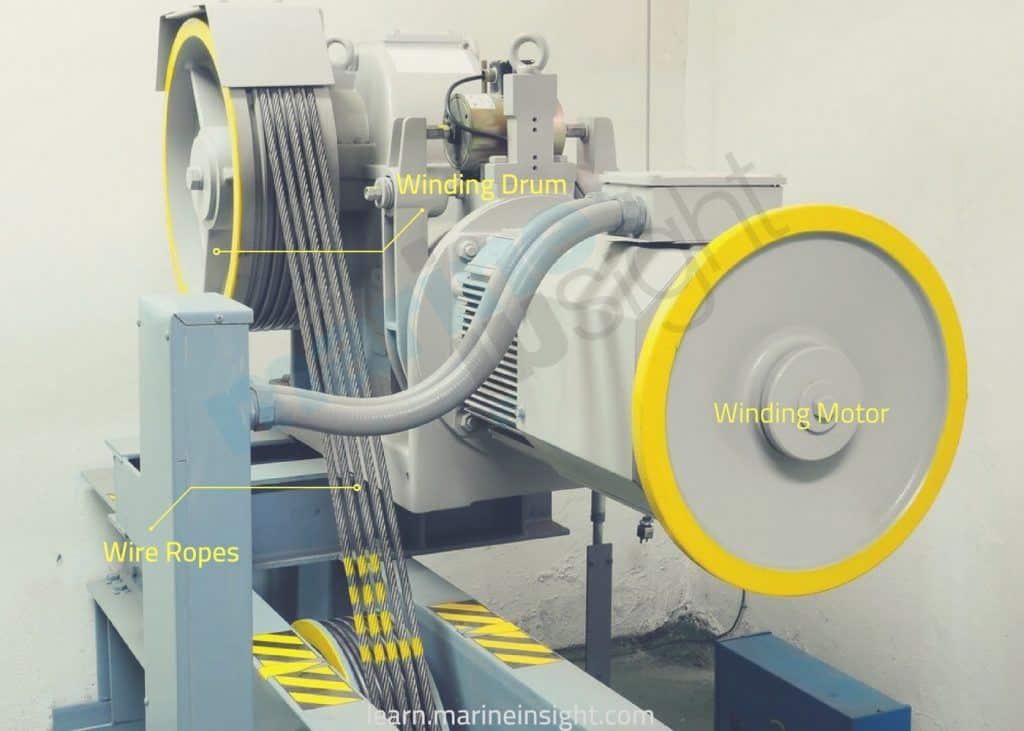

4) Winding Machine

The winding machine of marine elevator assembly is of single wrap traction geared type. Electric motor brakes and worm reduction gear is assembled robustly on the stand made of steel. The construction is such that intermittent operations can be carried out in high frequency. The brake is of DC electromagnet. Simultaneously, with shutting off of the current, the braking wheel is held with the force of the spring, resulting in stopping of operation. At the same time, the arrangement allows a full braking holding force while stopping.

5) Elevator Cable

The cable used is specially manufactured for marine elevators. It has reforming wires (galvanized wire ropes) and is devised to operate smoothly in the cage tunnel with cable tension weight.

6) Control Panel

The control panel is of drip-proof construction floor type. The construction is such that the built-in parts can withstand the rolling of the hull.

7) Operating equipment

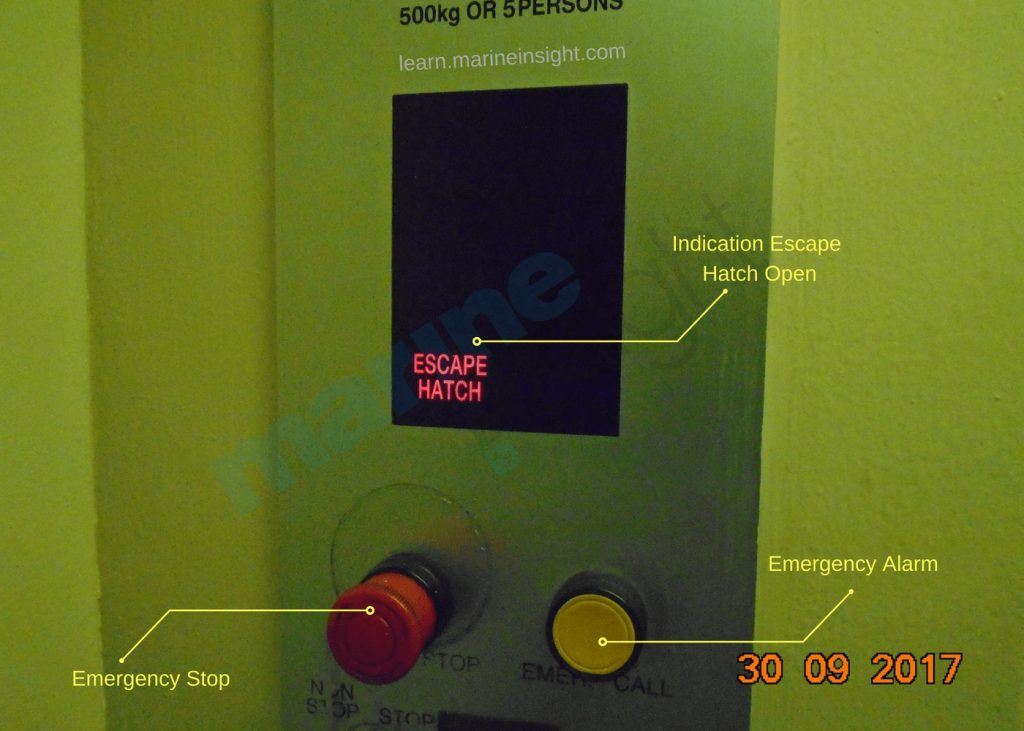

The following devices are provided on the operating panel in the cage:

• Same number of operation buttons as the number of stop floors

• Emergency stop button

• Alarm button for emergency

• Rolling and pitching indicator

• Escape hatch indicator

• Position indicator

• Overload alarm and buzzer

• Door open and close buttons

• Pilot lamp for the position of the cage

• Home landing switch (change switch with key)

Safety Equipment

1) Interlock switch

It is provided at the entrance door on each floor. It ensures that the doors on the floors, other than the level where the elevator cage is stopped, are not opened.

2) Emergency Stop Switch

The emergency stop switch is provided in the operating panel both inside and upper outside the cage. In case of an emergency, the elevator can be stopped and initiate an alarm in the engine room to make them aware of the emergency. The emergency stop device is interlocked with the reduction gear and is caught by rail for stopping the cage.

3) Brake

It is of the DC electromagnetic type. When a brake is operated, simultaneously with cut off of the current, the brake wheel will be held with the force of spring.

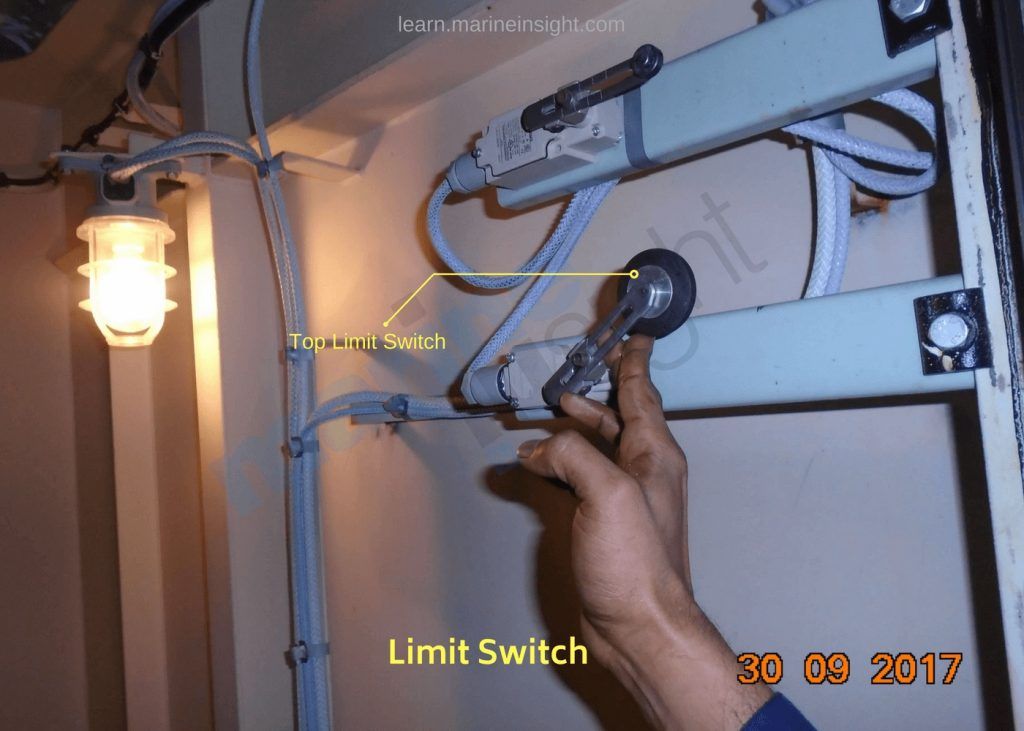

4) Limit Switch

The limit switches are provided at the top and bottom of the elevator trunk to stop the elevator when the limit switch is operated.

5) Buffer Equipment

The spring type buffer equipment is provided at the bottom part of the elevator trunk both for the cage and the counterweight. In a severe case of freefall, the buffer spring will help to minimise damage.

6) Communication

As communicating equipment at the time of emergency, the emergency alarm bell button and telephone are provided in the cage.

7) Overload protection device

The elevator is so designed and manufactured that when exceeding the rated load, the cage door will be kept open and an audible alarm will ring continuously inside the cage automatically.

8) Emergency exit switch

In case the cage stops incidentally anywhere other than landing floor and the emergency exit is opened by the passenger, the control circuit is cut off automatically.

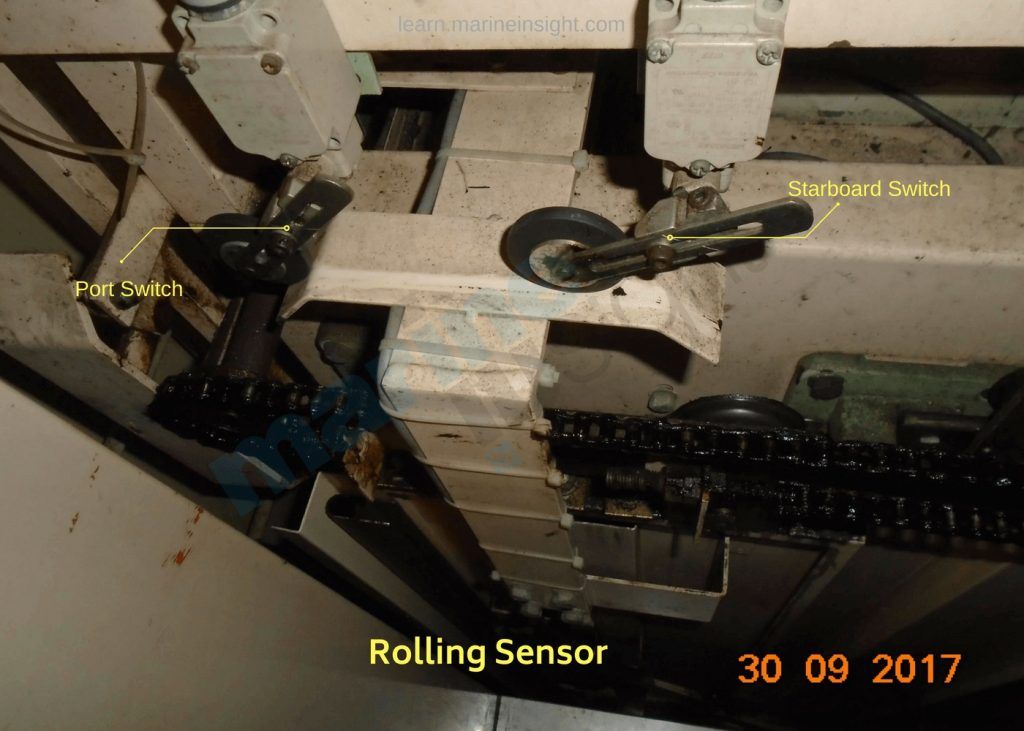

9) Rolling and pitching switch

Rolling switch or when pitching switch is operated, the elevator is moved to the nearby floor, stopped and the door cage is opened. For about 15 minutes elevator remains stopped and it reverts automatically after that, and usually comes back to operation when the switch is reset or it doesn’t detect any rolling or pitches beyond the limit.

Rolling and Pitching: Inclination 10 degrees in bow and stern. 15 degrees in port and starboard

Inspections & Maintenance to be carried out

The elevator maintenance and inspection/testing plan should be made under the guidance of the lift manufacturer or relevant classification society survey requirements. It is not possible for ship’s staff to perform all maintenance and testing/ evaluation of shipboard passenger elevator, hence such tasks should be given to competent service personnel approved or recognized by the lift manufacturer.

For basic troubleshooting:

1) Check for motor amperage and motor fault

2) Check for any improper installation environment

3) Check the cooling system, clean air filter, if required

4) Check for unusual vibrations and noise

5) Check for unusual discolouration or overheating

6) Screws and bolts might become loose due to vibrations, temperature changes, etc. Check they are tightly secured and retighten if necessary

7) Check for corrosion and damages on insulating materials and conductors. Measure the insulating resistance using megger.

8) Confirm the operation of limit switches and the overtravel limit switch. Also, check door interlock operation, door contact switch operation and position switch indicator operation.

9) Check the level of lubricating oil in the oil pot is sufficient for lubrication of guide rails. Also, check the level of gear oil for the gearbox assembly.

10) Try out the emergency stop, emergency alarm and communicating devices to ensure they are functioning

11) Check the clearances between the counterweight and the cage. Also, measure the clearance between counterweight and buffer. The clearance between counterweight and buffer to be measured with the cage stopped at the highest position

12) Carry out the load test for the elevator. Load test has to be carried out in progressive steps and parameters have to be recorded for each step

13) Check for braking efficiency. Brake test for the traction is to be carried out with 25% more load than rated. If required to adjust the braking torque for traction machine, the length of the spring needs to be changed with the help of turning the nut

14) Check temperatures at various places such as the stator core of the motor, gear oil casing of traction machine, inverter controller and control circuit and machine room

One of the critical equipment in marine elevators is the inverter fitted to convert AC to DC current for the function of the control circuit. The inverter consists of many electronic parts such as semiconductor devices. The following parts may deteriorate with age because of their structures or physical characteristics, leading to reduction of performance or failure of the inverter. For preventive measures, the parts must be checked and changed periodically.

1) Cooling Fan

The cooling fan cools heat generating parts such as the main circuit semiconductor devices. The life of the cooling fan bearing is usually 10,000 to 35,000 hours. Hence, the cooling fan must be changed every 2-3 years if the inverter is running continuously. When unusual noise and/or vibration is noticed during inspection, the cooling fan must be changed immediately.

2) Smoothing capacitor

A large capacity aluminium electrolytic capacitor is used for smoothing the DC in the main circuit, and an aluminium capacitor is also used for stabilizing the control power in the control circuit. Their characteristics are adversely affected by the ripple current. When the inverter is operated in an ordinary, air-conditioned environment, change the capacitor about every 5 years. When 5 years have elapsed, the capacitor will deteriorate more rapidly. Check the capacitors at least every year for the following:

• Case (side face and bottom face for expansion)

• Sealing plate (for remarkable warping and cracks)

• Explosion proof valve (for excessive valve expansion and operation)

• Appearance, external cracks, discolouration, leakage. When the measured capacitance of the capacitor has reduced below 85% of the rated capacity, change the capacitor.

3) Relays

To prevent contact fault, relays must be changed according to the number of accumulated switching time.

Best Practices For Marine Elevator Operation :

1. It is always advisable to use the elevator when moving to more than 2 floors (2nd and above). The ship staff should always be instructed to use stairs for the first level

2. The inside of the elevator and the car duct must be fitted with proper lights

3. Elevator on ships can be provided with the ventilation system. When the elevator is not in use, ensure to switch off the fan

4. The elevator of the cargo ship also goes to the engine room deck. Ensure to clean the flooring from any oil or slippery substance which may get carried over. The flooring of the elevator is of non-slippery type, but oil or grease can make the space slippery and may lead to slip/trip

5. The elevator doors are type approved fire doors. Ensure not to do any repairs without consulting the company and the manufacturer

6. All ship crew members must be trained regularly on how to use emergency escape inside the elevator and how to assist when someone is trapped within

7. Marine elevators are provided with interlock option, which prevents the elevator to go in the engine room if CO2 alarm or alarm for other fixed firefighting system is raised

8. In case of any damage or breakage of the part/equipment, never perform any welding or gas cutting without consulting the manufacturer

9. The main control panel room should be kept closed and the control panel room should be kept locked and the key should be with the responsible officer

10. Before performing any maintenance on the elevator, ensure to turn off the main power

11. Warning labels and placards must be displayed on all the floors at the elevator entry

12. Ensure to switch off the elevator when any rough weather warning is received or when the ship is rolling heavily

13. During dry dock or when the ship is about to undergo a power switch (shore power), park the elevator car and switch off the elevator if needed

How to escape in a marine elevator during an emergency?

This is a standard procedure to escape from the emergency escape hatch inside the marine elevator cage in case of an emergency. It is advised that it’s safer to remain inside of the cage and wait for help but in case of an escape situation following steps to be followed:

1) Be calm and take actions carefully when the elevator stops suddenly or when an emergency occurs

2) If the elevator stops suddenly with the cage near the landing door, the passenger can open the doors by hands and escape from the elevator easily

3) If not possible to escape from doors, push the emergency stop button and emergency call button and wait for communications from outside

4) In case of failed communications from outside, open exit cover at the ceiling of the cage. Climb up to the cage at the ceiling, escape through escape hatch by using the ladder

5) Once the emergency door is opened, the closing of it will not bring the elevator back to the original operative condition. To reset the system, use the RESET BUTTON on the control panel.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Great article. Covred all prospects.

I personally learned a lot from this blog. As a lift dealers in Chennai, i have learned this new thing. Thank you marine insight.

This is Nora Kamiñetzky, director of Revista del Ascensor. Revista del Ascensor is the most important latin american elevator magazine and has turned 23 years in the market. I found this article very interesting and wish to publish it, as we do with others.

Of course we will published the source and give you the credits.

I hope you will allow us to do it.

Thank you very much

Regards

Nora Kamiñetzky

@Nora: Yes, you can use the information providing due credits to the author and the website. Please do share the snap of the published article with us too 🙂 at info@marineinsight.com