Hydraulic Oil Leak Starts Fire in Engine Room

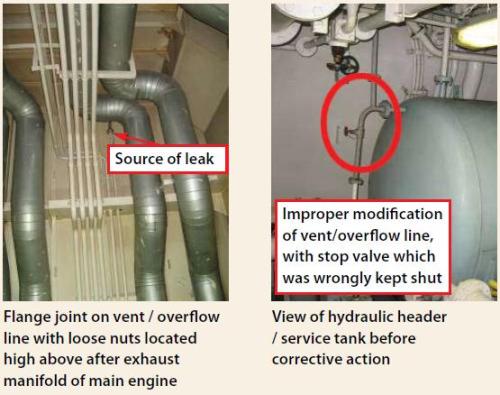

On a tanker on passage, the fire alarm suddenly sounded. At the same time, the engine room crew saw small flames and smoke rising from the after exhaust manifold and cylinder heads of the running main engine. After extinguishing the localized fire, it was discovered that hydraulic oil from the cargo pump system had leaked from a flange connection in the vent/overflow line situated directly above the main engine cylinder head platform.

Result of investigation

At the previous discharge port, a submerged cargo pump hydraulic motor had malfunctioned. In preparation for carrying out repairs, an engineer had closed the vent-cum-overflow line valve located before the service/header tank without draining the line;

Due to the residual pressure in the line, the flange connection (later found to have loose fasteners) leaked and a fine spray of hydraulic oil began falling on the hot surfaces on the top of the exhaust manifold and ignited after attaining self-ignition temperature.

Root cause/contributory factors

Inadequate work planning – line was not depressurised/drained before closing of valve before header tank;

Inadequate management of change – the hydraulic piping had been modified some years ago to tap off a new branch line before the header tank leading to an offline oil filtering system. A stop valve was fitted before the branch without properly assessing risks;

Inadequate communication – the engineer who closed the valve failed to inform other members of this fact.

Corrective/preventative actions

Ship’s staff removed the stop valve from the vent line, and the piping was re-modified to ensure that the offline filtration circuit was independent of the vent/overflow line;

All joints in the hydraulic system lines were inspected for proper condition and tightness;

Sister vessels fitted with the same filtration plant were advised to check the lines to ensure that the overflow line could not be inadvertently shut. All vessels were instructed to thoroughly inspect all nuts and bolts on flange joints and tighten them.

Reference & Image Credits: nautinst

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

- Real Life Incidents: Near Miss In Open Water And Good Visibility

- Real Life Incident: Poor Situational Awareness Leads to Collision

- Real Life Incident: Monkey’s Fist Knocks on Office Window

- Real Life Incident: Paint Storage Slip-Up On Ship

- Real Life Incident: Checklist Mentality Is A Burning Problem

- Real Life Incident: Vessel Speed Exacerbates Bank Suction

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.