Real Life Incident: Hot Fuel Oil Incapacitates Two Crew For Months

Crew on a bulk carrier in port were planning a transfer of heavy fuel oil from a storage tank to fuel oil settling tank no.1 (FOST-1). The fourth engineer and an oiler were tasked with this job.

For the last six months, the crew had been using fuel oil from fuel oil settling tank (FOST) no. 2 and service tank no. 2. while FOST-1 and its corresponding service tank were kept empty. FOST-1 was therefore deemed to be empty by engine crew.

The fourth engineer was directed to open the lower manhole of FOST-1 before starting the transfer, to verify that there was no sludge that could contaminate the bunkers. Before doing this, he checked the fuel oil gauge, and opened the FOST-1 drain valve. Both actions indicated that FOST-1 was empty, much as he and other engine crew had previously assumed. He noticed that the temperature in FOST-1 was elevated (about 78° C), which was unusual for an empty tank, but assumed that heat conducted from adjacent tanks accounted for this.

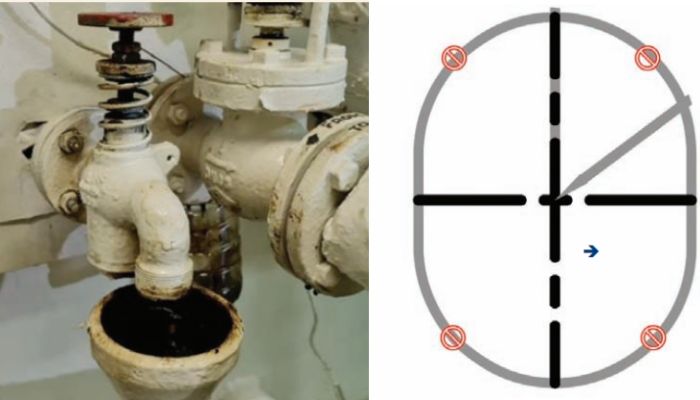

‘Without incident, leaving four opposite each other still tightened, as shown in the diagram. The engineer proceeded to loosen these last ones, starting from the bottom nuts. At this stage, he noticed a small amount of fuel oil seeping out of the manhole. Assuming that this was the expected seepage of fuel oil which normally remains stuck to the tank sides, he continued undoing the nuts. As he loosened the last two bolts, fuel oil started to seep out in larger quantities.

Now concerned about the increasing seepage, he attempted to reinstall and retighten the nuts. However, the flow and high temperature of the fuel oil spilling on his hands and torso were too much for him, and he had to abandon the area, as did the oiler helping him.

Two other engine crew, both in the vicinity, were alerted to the situation and raised the alarm. Both the fourth engineer and the oiler had skin burns over the lower chest and abdomen. The victims were immediately transferred to the vessel’s hospital for first aid and an ambulance was arranged to evacuate them to a local hospital. One victim was discharged from hospital after two months of treatment, the other only after three months of treatment.

After the accident, it was found that the oil level gauge and its drain valve were partially clogged with sludge. Once cleaned, the oil level gauge worked correctly. The fuel level in FOST-1 was found to be at the lower edge of the manhole; a volume estimated to be nine cubic metres. It is estimated that eight cubic meters were lost into the engine room.

Lessons learned

- Always try to be aware of confirmation bias in your daily work and life; question your assumptions and double check the facts.

- Fuel gauges and drain valves can become blocked with sludge and not indicate the correct level of fuel or drain as designed. Sounding pipes, which in this case were not fitted to the FOST-1, are an efficient and reliable double check on liquid levels within tanks.

Reference: The Nautical Institute

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.