What is a Cable Laying Ship?

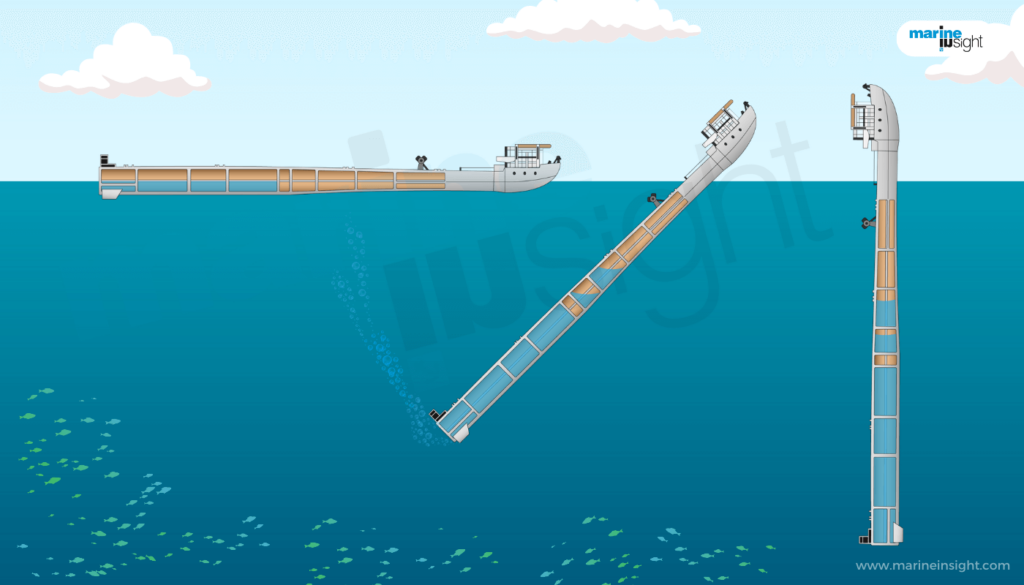

A Cable Laying Ship is a sea going vessel designed to lay underwater communication cable networks. Since, in today’s times, underwater cable connectivity has become more relevant and useful, the importance and relevance of a Cable Laying Ship has also increased manifold.

Purpose of Cable Laying Ship

A Cable Laying Ship is created specifically to cater to the purpose of laying cable lines underwater. But at the same time since cable laying work does not take place round-the-clock and throughout the year, a Cable Laying Ship is also additionally used as research ships to monitor various happenings in the oceanic and sea waters. A Cable Laying Ship is built with every modern gadget required to make the process of laying the intricate lines of cable on the oceanic floor simpler. It is enabled with Dynamic Positioning and Dynamic Tracking systems which pinpoint the exact location of the ship in the mid-ocean and lay the underwater cable lines appropriately.

Size of Cable Laying Ship

The torso of a Cable Laying Ship is huge because of the nature of the work it undertakes. Most of the cable laying ships have a tonnage of over 11000 tons and are capable of laying not just one line of underwater communicative cable lines but two-three lines in addition. And because it is so bulky in its torso, a cable laying ship cannot be used for operations in shoals or shallow waters where there is a chance of land merging with the waters because the shallowness of the water tends to curtail and hamper the movement of the cable laying ship. Another specific feature that is unique to a Cable Laying Ship is that is built with every damage control tool and equipment that might be necessary in case there is any damage done to the underwater cable lines and contains both pneumatic – operated by air and hydraulic – operated by liquid (oil or water) operating systems for the process of laying underwater cable liness

The size specification of a Cable Laying Ship depends on the depth of the ocean floor where it is required to be positioning the cable lines. If the depth of the ocean bed or floor is more, then the size of the ship is bigger and huger, whereas if the depth of the ocean bed or floor is not much, then the Cable Laying Ship’s size tends to be smaller. However, it has to be noted that whether smaller or huger, the size of a cable laying ship many times bigger than that of a normal ship because of the extensive nature of the ship’s purpose.

In today’s times, more than overhead cable networking, underwater cable lines have far more reachability and penetrability. The underwater cable lines do not get much affected by natural calamities unlike their land counterparts which get easily affected by occurrences like rain or snow. Furthermore, since underwater cable lines are far below in the deepest part of the ocean, they can be laid uninterrupted over a long length unlike land cable lines which have to face a lot of issues pertaining to the distance of the cable and so and so forth.

Conclusion

Because laying an underwater cable line is so different but practical in the contemporary world, the work and the purpose of a Cable Laying Ship becomes very helpful to the world. Like various channels which help to fulfil the many necessities of man’s ever-growing world, the Cable Laying Ship is yet another brilliant creation by man, created just to solve his communication and networking problems in a completely different way.

References: Brighthub, Globalsecurity

Latest Type Of Ships Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories