What Are Magnetic Strainers And Filters?

There’s a major misconception about the word filters when it comes to marine engineering equipment. As an equipment which carries out filtration is called as a filter but indeed this word is a misnomer and this may appear legit when you understand the concept behind it.

Filters and Strainers – What is the difference?

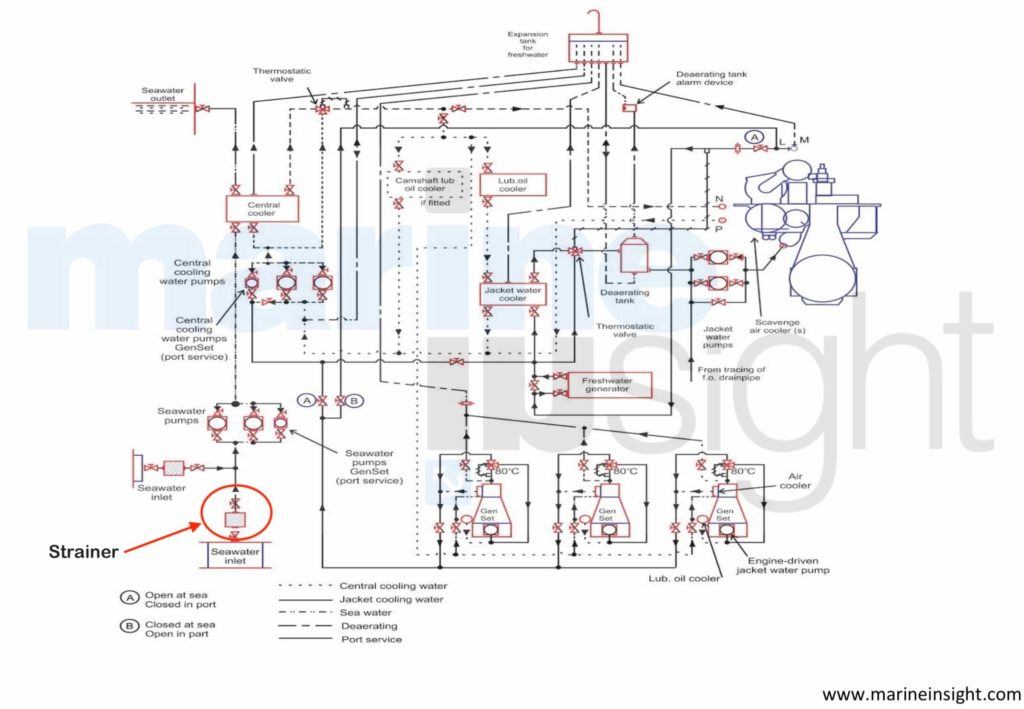

Filters and strainers both substantially filter out the contaminants in fuel oil, lubricating oil and water onboard a ship but there’s a fine line of difference between filters and strainers as the latter are installed on the suction side of the pumps to prevent the contaminants, debris or foreign matter from entering and damaging the running parts of the pumps.

Strainers are generally of the full flow type and hence their application is entirely different from the filters.

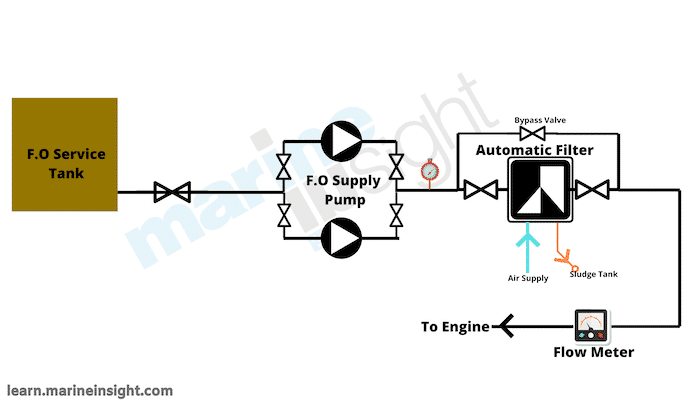

Filters on the contrary are fitted on the discharge side of the pumps and could be of the full flow or by-pass type.

The media filtered is generally the foreign particles or contaminants which are diminutively small and are unable to be filtered when in circulation.

A clean strainer causes a drop in pressure in the line which could be attributed to the rate of flow, the viscosity of the fluid being filtered, the size of the filter and the size of particles being removed.

There is a distinct type of filter called as auto back filter which works on the principle of pressure drop before and after the filter. The auto back wash filter cleans itself when the pressure drop increases beyond a certain value by blowing back air from outside to inside.

Related Read: Viscosity Meter and Viscosity Controller Used on Ships

These filters could be of various types mainly simplex filters, duplex filters, by-pass and full flow filters.

A simplex filter is a simple basket filter which is fitted in the line; a duplex filter is arranged in a pair and hence one filter could be used and the other could be cleaned and kept as stand-by; a bypass filter takes a part of the fluid from the line, filters and returns it back to the suction side of the pump; while a full flow filter takes the complete amount of discharge from the pump for filtration.

Several precautions are taken before cleaning these filters and the instruction manuals should be adhered to before opening them.

Thus, the fluid is treated accordingly before it could be filtered by a strainer to get the maximum separating efficiency.

Fuel oils and lubricating oils are generally heated before filtration as the specific gravity of the constituent particles reduce with the increase in temperature.

The specific gravity of the oil is reduced at a greater rate than the specific gravity of the contaminants and hence the difference in the specific gravities is comparatively higher when the oil is heated which aids in the filtration process.

Related Read: Filters and Strainers on Ship – Types and Uses

Classification of Contaminants

The contaminants, mainly metallic in nature are divided into three main categories, diamagnetic, paramagnetic and ferromagnetic.

Diamagnetic materials are actually repelled by the magnets and in extreme cases, weakly attracted to the magnets when subjected to very strong magnetic fields. Further, these materials do not retain the magnetic properties when the external magnetic field is removed.

Paramagnetic materials on the contrary are weakly attracted to the magnets and do not retain the magnetic properties when the external magnetic field is removed.

Ferromagnetic materials on the contrary are strongly attracted to the magnetic fields and retain the magnetic properties when the external magnetic field is removed.

Strainers act as the first point of contact for the removal of impurities and hence are supposed to run clean.

Magnetic Strainers and Filters

Fuel oil filters are generally fitted with cylindrical bar magnets to attract the magnetic particles present in the fuel oil. The magnetic particles include small iron particles which are not included in the BDN and go neglected.

The iron particles are tested by the IP 501 method by an approved lab ashore. These particles are minutely small and hence cause the wear of the moving parts of the engine. The iron particles are generally in the range of 0-50 ppm in the fuel.

The magnets could be found in the purifier feed pump filters, transfer pump filters, fuel oil supply pump filters and fuel oil circulating pump filters. Thus they’re called as magnetic filters.

It must be understood that the lubrication of the running parts of the pump is carried out by the fuel oil itself, thus the fuel should run clean to avoid the wear of the same.

A gear pump running inside the casing has very small clearances between the gears and the casing. Wear may hence decrease the efficiency of the pump as the fuel will return back to the suction side of the pump causing a reduction in the pressure delivered.

The fuel pumps are mainly responsible for delivering the fuel to the injectors in an engine which indeed develop a very high pressure and also vary the amount of fuel injected as per the load demand.

The fuel pump plunger and barrel have very close tolerances and hence magnetic particles embed in the material of such components and affect the engine performance, if not removed from the engine.

Particle size is the most important factor when the fuel oil is being treated. The ferrous or ferromagnetic particles are thus very small which easily pass through the filter holes and cause inevitable dangers to the engine.

Cleaning Fuel Oil Line Magnetic Strainers and Filters

It is advised that the filters should be cleaned at regular intervals depending upon the suction pressures in the line.

Cleaning these filters isn’t easy the way it seems. Majority of the engineers remove the filter after isolating it, clean it in diesel oil, blow air and then put back in the casing. This is the most common mistake that all engineers fall prey to while cleaning the filters.

With the fuel oil sulphur regulations in place, the vessels change over from HFO/VLSFO to LSMGO and vice-versa frequently while trading in US gulf regions.

The tendency of LSMGO is to wash away all the catalytic fines, sediment, debris and the magnetic impurities and clog the filters which stay in the casing until cleaned. Thus, almost all the vessels face the problem of the filters getting choked again and again because they don’t clean the casings and the magnets inside the filters. Upon careful observation it could be found out that the casing accumulates a lot of sludge at the bottom which must be removed.

Filters in general are not used to clean the engine as they are just used to pick up the larger contaminants and ensure that these do not reach the engine. Thus, a proper cleaning system is thus required to clean the fuel which includes proper treatment of fuel and cleaning in centrifuges.

The fuel should be sent for analysis as per the PMS to an external shore laboratory for the detailed contaminants’ report and a suitable action should be taken for the same. It indeed determines the quality of the bunker and separation efficiency of the filters and the purifiers onboard a ship.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.