Viscosity Meter and Viscosity Controller Used on Ships

As the fuel prices go sky high, ships are using lower grades of fuel for saving its operational cost. The fuel used for burning in the auxiliary engine and main propulsion plant is normally heavy fuel oil. Along with other properties, the viscosity is an important property which determines the efficiency of fuel combustion and of the marine engine.

The viscosity of fuel oil depends on the grade of oil. If the viscosity of the fuel oil and its viscosity index are on the higher side, it would lead to more difficulty in achieving atomization state and poor combustion inside the engine cylinder.

Understanding the Important Definitions

Viscosity

In simple term, it can be defined as ‘resistance to the flow of the fluid offered by its internal layers due to internal frictions’. It is measured in centistokes (cst).

Less the viscosity, lesser the resistance to flow and the fuel can be easily atomized.

Viscosity index

It is an important factor in selecting any kind of oil, fuel or lube oil. It’s the measure of change of viscosity of oil with variation in temperature.

Since fuel oil is heated to achieve proper atomization, it should have proper VI. If it’s on the higher side, it will be difficult to alter the viscosity of oil by the heater.

Atomisation

It is the process of breaking the fuel particle into fine mist spray under high pressure to improve the surface area of contact of fuel and air for proper combustion.

Viscometer or Viscotherm

The viscosity of the marine bunker HFO fuel when supplied at 50 ̊deg C varies from 180cst to 380 cst. The fuel is heated and the viscosity of the fuel is reduced to 13~15 cst at the time of injection in the engine by means of electrical or steam heaters or both.

The viscosity to the high-pressure fuel oil pump has to be maintained approximately at 13 cst to achieve efficient combustion.

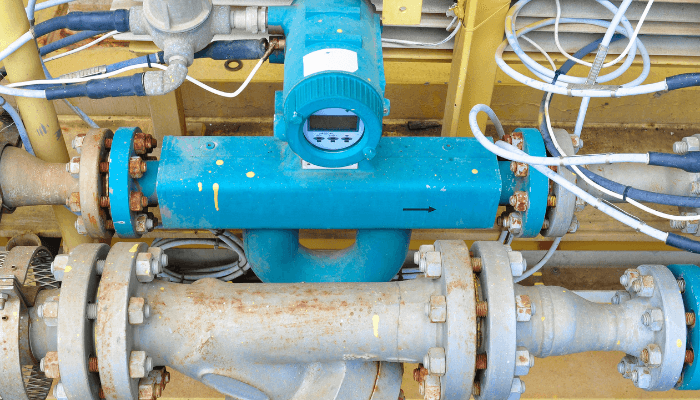

A viscotherm or viscometer is used to measure the viscosity of fuel oil at the fuel injection system of the engine.

Construction and Working of Viscosity meter

It consists of a capillary tube inside of which a gear pump is fitted which rotates at very slow rpm (say 40 rpm). There is an outside casing provided for the capillary tube.

When the oil passes through the casing, some part of the oil pass through the gear pump and its capillary, and some part of the oil passes over the capillary tube. Hence a flow difference occurs inside the casing. The oil inside the tube maintains a laminar flow and outside the tube maintains a turbulent flow.

The pressure difference between outside and inside of the tube is measured which is directly proportional to the viscosity of the oil. Hence oil viscosity is maintained.

Viscosity Controller

The viscosity controllers actact the controller of the 3 way valve from which steam is passed into the heater or bypassed from the heater as per the position of the control valve.

Construction and working

Normally pneumatic control system is used with bellows, flapper and nozzle. The output signal from the viscometer is connected to measured value bellow of the viscosity controller.

Another bellow is supplied with set point of the required viscosity and both the bellows are connected opposite to each other to complete a flapper nozzle control system. The output of flapper nozzle is the controlling signal of fuel oil heater 3 way valve.

A 3-way valve has 2 openings in which one is inlet and 2 are outlet. One outlet goes through the heater and one outlet is connected to a bypass line of heater.

When the set value and measured values are same, no signal is given to control valve and valve position remains same. More of the steam bypasses the heater.

When the measured value decreases, the output signal opens the control valve to steam side so that more steam is supplied and viscosity can be brought down.

It is important to have a better grade of marine fuel oil with proper viscosity index for maintaining proper efficiency of engine and to reduce wear down of the fuel injection parts.

You may also like to read- High Speed Centrifuge on Ship

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

The twin capillary viscometer has been the industry standard for a great many years and though it still enjoys popularity with many users, the vibrating element viscometers are increasingly coming to dominate the market.

The first of these was the Sofraser viscometer (packaged by Alpha Laval) but the major breakthrough came with the Emerson (Solartron) 7829 ViscoMaster some 10-12 years ago.

One of the drivers of the marine industry is the ideal of un-manned machinery space which must cater for smaller crews with less skills. Vibrating element viscometers can deliver virtually maintenance free operation as they are self-cleaning and they do not require periodic re-calibration.

Following the 7829 Introduction VAF brought their Viscosence to the market.

However, maintenance and skills are not the only deciding factors. There is a trend also toward parameter based engine management and to CBM. To be effective these require accurate and detailed reporting of parameters.

The Viscosence, like the twin capillary viscometers, measures dynamic viscosity and uses the reported fuel density to convert to kinematic viscosity. This means that it performs the fuel heater control function very well and brings low/no maintenance qualities to the application.

On the other hand the 7829 Viscomaster and the new LEMIS DC 52 are displacement sensors. This means they measure both the dynamic viscosity and the density accurately and simultaneously and in real time.

This means not just that they can report the true kinematic viscosity for heater control but that they also deliver a range of other properties important to the ship’s engineer for operations and of value to engine manufacturers for CBM and oil record verification.

Thus they report the following parameters:

Kinematic viscosity at the fuel temperature – heater control (4-20mA)

Temperature

Density at the fuel temperature – useful for MARPOL Annex VI reporting and mass flow calculation in conjunction with the volumetric fuel flow meters.

Density at 15degC – a quality parameter

Density at 98degC – operational factor, the density as the fuel passes through the centrifuges;

Kinematic viscosity at 100degC – a quality factor

Ignition Index, both CCAI and CII – now included in ISO 8217 2010, the CCAI, density and kinematic viscosity all form the operating envelope for the engine.

At least one engine manufacturer logs all this data for CBM and oil record verification. As engines progress toward parameter based management, some of these parameters may become increasingly used for that purpose.

It is suggested that these measurements may permit at least one way to comply with the objectives of CEMS as and when MARPOl reporting tightens up – something suggested in MARTOB and NERA reports to the EU, the alternative being inline density and sulphur analysers at each engine.

many thanks for the valuable information.

I hope that I can find a way for fuel oil viscometer and control to install in ships.

we have 8 vessels with different capacity and we need to install a new viscometers and heating control and we look for a good quality, we have some vessels with steam heating system and some electric heaters.

used blended fuel is different Cst. from 30 up to 120 Cst

hope to help to find.

thanks in advance

Thanks for the info Sir. Helped me a lot

Hi, this is great information. I am looking for a fuel oil viscometer. I have seen some of the companies from the comments and I am looking for a quote. Do you know anything about the Hydramotion Viscojet? It has not been mentioned here but I am in contact with them. Thanks

Thanks for this valuable information

I am lloking for the latest viscosity regulator to use onboard the ship for the heavy fuel oil