What is Power Balancing of Marine Engines?

The efficiency of the overall ship depends a lot on the efficiency of the engine running in its engine room. One of the important factors to ensure efficiency of marine engines is to control the power produced from each of its cylinder. The process of making fine adjustments to achieve equal power from all engine cylinders is known as power balancing.

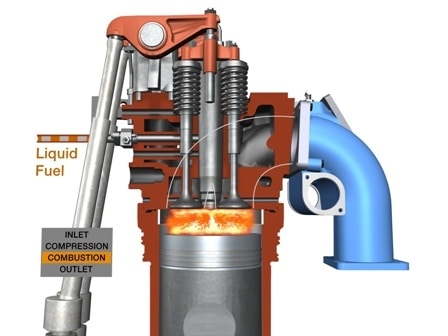

Power balancing of engines is carried out by making minor adjustment to fuel pumps of individual cylinders. The quantity of fuel injected in the cylinder plays the most important role in power balancing.

The small adjustments made to the fuel pumps should be such that the units are not overloaded and the exhaust temperature doesn’t go beyond the safe limits. It is therefore necessary to be extremely careful while carrying out adjustments for power balancing.

Important Points While Carrying out Power Balancing of Marine Engines

Power balancing should be done in such a way that:

- Individual units are not overloaded

- Exhaust temperature of the units do not rise above the acceptable levels

- Fuel pumps are able to cut off when engine is stopped

Things to check while making Adjustments for Power Balancing of Marine Engines

- Fuel pump rack position

- Exhaust and cooling water return temperatures for each cylinder of marine engine

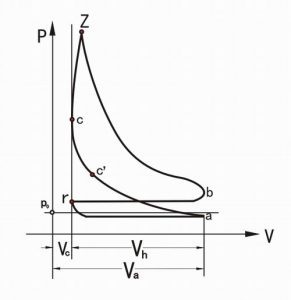

- Measurements from indicator diagram

- VIT adjustment

It is to note that not all cylinder units show equal exhaust temperatures. However, for each engine the figures follow a certain path which can help in accessing a situation. Peak or maximum pressure of the cylinders should also be checked along with cylinder temperatures.

If proper care is not taken during power balancing, the marine engine can become unbalanced, leading to other serious problems.

Unbalanced situation of the engine might lead to

- Overloading of bearings and running gears

- Overheating or bearing failure

- Piston blow past

- Overheated or piston seizure

- Vibration followed by fatigue

- Fatigue cracking in bearings, studs, or bolts

- Cracking in crankshaft

- Failure of holding down bolts

If you are the watching keeping officer, you must check the following things to ensure smooth power balancing of marine engines:

- Check relevant temperature and pressures (exhaust and cooling return temperatures)

- Check lubricating oil and turbo charger pressures

- Check for any unusual noise or vibration

- Keep an eye on the exhaust for any kind of smoke

- Check if the turbocharger is running smoothly without surging or panting

- Check fuel pump settings

- Measure clearances and timings of fuel pumps when engine is not working

- Ensure that fuel injectors are changed at regular intervals of time after cleaning and testing. A faulty injector would not only cause loss in power but would also lead to overloading of other cylinders as the governor would try to maintain the normal total power output

- Carry out maintenance of the marine engine at regular interval of time and note down any deviation from the normal running speed

- Any error found should be rectified at the earliest.

Do you have any more important information on power balancing of marine engines? Kindly share it with others in comments below.

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

dear sir. i want to know how to calculate cylinder power balanc?

1)how to calculate cylinder power balanc?

2)Power card@Draw card calculate?

Similar queries are already answered in our forums. Please visit- https://forums.marineinsight.com

please share how lapping of fuel valve nozzles and fuel valve body should be done along with the spacers as in daihatsu auxiliary engines , it is a normal practice these days to limit the spare parts supplies by the companies , in order to keep the machinery trouble free , with limited supplies , nozzle lapping has become very important, kindly through some light on it.

It is not recommended to lapp nozzle needles .Needle valve and seat have a different angle to prevent seizure. Its impossible to lapp auxiliary engine nozzles on board correctly. Only temporary results with increased Nox emissions due to bad ignition will result. In eventual failure.

kindly tell me what are the protection under UMS condition for main engine overload

dear sir, what is the procedure of adjusting fuel pump ?

@Debabrata: For 2 stroke engine, usually adjusted from the VIT, and for 4 stroke, individual plunger can be adjusted.