Important Mooring Equipment On Ships

Every mooring operation depends not only on the skill of the crew but also on the reliability and correct use of the equipment installed on deck. Over the years, mooring systems have evolved significantly, yet the fundamentals remain rooted in mechanical efficiency, safe line handling, and controlled tension. Understanding the main mooring equipment is therefore essential for any deck officer or rating involved in berthing, unberthing, or shifting operations.

A Guide to Mooring Operations Onboard Ships provides a structured overview of the equipment commonly found on mooring decks, explaining how each component contributes to a safe and stable mooring arrangement. Below is a simplified breakdown of the most important mooring equipment used onboard today.

1. Mooring Winches

Mooring winches are the backbone of any mooring system. They are designed to handle, heave-in, pay-out, and hold mooring lines under varying loads. Modern ships typically use hydraulic or electric winches, each fitted with features such as automatic tensioning or constant-tension systems, depending on the vessel type.

A winch’s performance is influenced by braking capacity, drum design, and the condition of its mechanical components. As stressed in Chapter 4, winches require meticulous upkeep, as even minor faults can compromise line tension control during critical manoeuvres. Improper synchronisation between multiple winches is also a recurring cause of mooring incidents.

2. Capstans

Capstans provide additional pulling power for line handling, particularly on the aft mooring deck, where heavy stern lines must be brought to the winch drum or bitts. They are vertically mounted and designed for short heaving tasks rather than continuous operation.

Although capstans may appear simple, their safe use requires proper coordination. Over-reliance on capstans for high-load manoeuvres can result in uncontrolled line movement, and Chapter 4 highlights the importance of using them within their rated load limits.

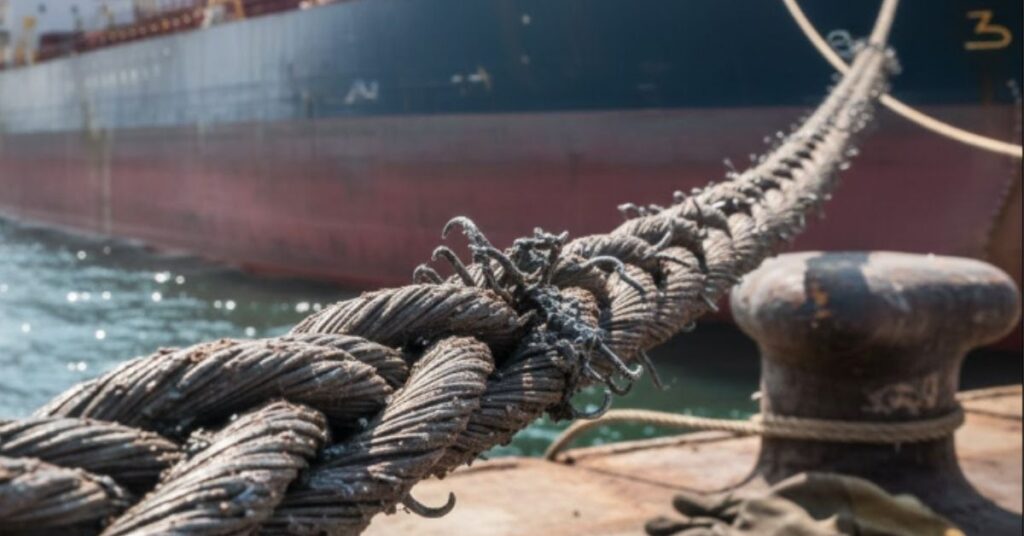

3. Bollards and Bitts

Bollards—sometimes referred to as bitts—serve as fixed anchor points around which mooring lines are secured after winching. Their placement and design allow the crew to belay a line safely using multiple turns to distribute the load evenly. Bollards must withstand extremely high line tensions, especially when spring lines are engaged.

On many vessels, bollards are reinforced with welded gussets to transfer line forces into the ship’s structure. Their effectiveness depends greatly on proper line leads from winches and fairleads, which is why bollards form an integral part of the overall mooring layout.

4. Fairleads and Pedestal Rollers

Fairleads guide mooring lines from the winch drum to the quay, ensuring the correct direction of pull and preventing chafing. Closed fairleads, open fairleads, roller fairleads, and pedestal rollers each serve specific purposes, depending on the vessel’s design.

Chapter 4 emphasises that improper line angles—especially when passed through non-aligned fairleads—can dramatically increase friction, overload the line, or lead to premature wear. Fairleads also help maintain a clean, predictable lead, reducing snap-back potential by stabilising line movement.

5. Chocks and Panama Leads

Chocks, including the widely used Panama chock, provide a smooth, rounded passageway for mooring lines, often at the ship’s side shell. Their robust construction allows them to handle high-tension loads from breast lines or spring lines.

Panama leads in particular are designed to accommodate large-diameter synthetic ropes and steel wires, ensuring minimal abrasion while maintaining a fixed lead angle. In rough weather or during vessel movement, these fittings play a vital role in distributing dynamic forces safely.

6. Stoppers

Mooring stoppers act as temporary holding devices when shifting a line from a winch drum to a bollard. Chain stoppers and rope stoppers prevent the line from sliding back during belaying. Chapter 4 notes that using the correct type of stopper for the rope material is crucial—using a chain stopper on a synthetic line, for example, can cause severe damage.

Stoppers may appear minor compared to winches or fairleads, but improper use is a common source of mooring accidents, underscoring the need for proper training.

Conclusion

A ship’s mooring system is only as reliable as the equipment that supports it. Understanding how winches, bollards, fairleads, chocks, capstans, and stoppers work—and how they interact with each other—forms the foundation of safe mooring practices. While this article highlights only the core components, the complete picture involves far more detail, operational nuance, and vessel-specific considerations.

The ebook A Guide to Mooring Operations Onboard Ships offers detailed diagrams, equipment characteristics, safety insights, and several additional concepts not covered here, making it a valuable resource for seafarers looking to strengthen their mooring knowledge.

You might also like to read-

- Types Of Mooring Lines

- Important Mooring Decks On Ships

- 5 Important Types of Mooring Every Deck Officer Should Be Aware Of

Disclaimer :

The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

About Author

Karthik, a former navigating officer now turned into a maritime tech innovator focused on advancing the shipping industry through digital transformation. As the co-founder of MarineGPT and a product leader at Marine Insight, he develops AI-driven solutions and tech tools to make knowledge accessible to maritime professionals worldwide.

Disclaimer :

The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

Related Articles

⚓️ Enhance Your Knowledge. Prevent Accidents. Stay Safe at Sea.

1. eBooks for Engine Department

Master machinery operations, troubleshooting, and safety procedures with expertly written guides tailored for marine engineers. Prevent costly breakdowns and onboard accidents through practical knowledge.

👉 Explore Engine Department eBooks

2. eBooks for Deck Department

Sharpen your seamanship, navigation, and cargo-handling skills with real-world case studies and practical insights designed for deck officers and cadets.

👉Discover Deck Department eBooks

3. eBooks on Electrical Fundamentals & Issues

Understand marine electrical systems, identify potential faults, and prevent onboard electrical failures with step-by-step explanations from industry experts.

4. Pocket Guides for Quick Reference

Compact, handy, and loaded with essential checklists—perfect for on-the-go reference during operations and emergencies at sea.

5. Combo Packs to Save Big

Access multiple expert eBooks at discounted prices. Ideal for professionals seeking complete safety and operational knowledge across various ship departments.

6. Digital Maritime Courses – Learn at Your Own Pace

Upgrade your competence with Marine Insight Academy’s online courses. Learn from industry professionals anytime, anywhere, and become a safer, smarter seafarer.

Subscribe To Our Daily Newsletter

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT