What is Crash Manoeuvring of Ship in Emergency Situation and what’s its Procedure?

“Crash” word is generally used to describe some kind of accident or damage when one object slams into another. However, in the shipping world, when the word is combined with the term “manoeuvring”; it becomes a procedure which is performed to avoid any kind of collision or accident.

Why Crash Manoeuvring?

In a sea going vessel, unlike land transport, there are no brakes that are provided to stop the ship when needed. The stopping of the vessel is done by reversing the rotational direction of the Main engine and thereby the propeller. This stops or reduces the speed of the vessel heading towards the collision course.

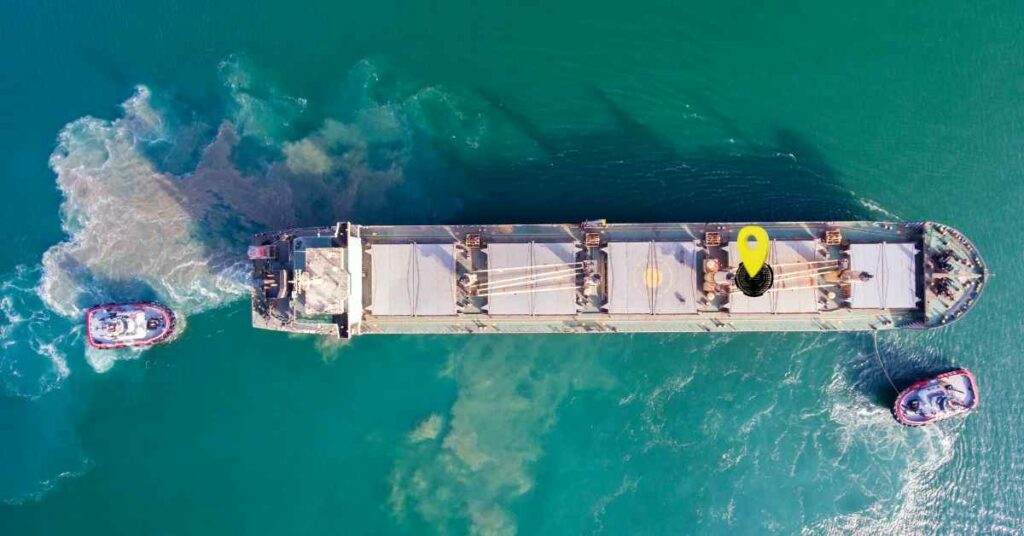

The crash manoeuvring is usually done to avoid any type of collision or crashing of ship to any other ship or structure (Jetty, land, Iceberg etc). In this type of manoeuvring the main engine is subjected to severe stress and loading, but the safety of ship and life is assured.

How to Perform Crash Manoeuvring?

Crash manoeuvring is turning the engine in opposite direction to reduce the heading speed of the ship. After certain time, the ship stops and starts streaming in astern direction. This is done by supplying starting air at about 30 bars from the air receiver to the engine. The stopping air is known as the brake air.

The brake air when sudden injected inside the engine cylinder, will try to resist the motion of the piston and the rotation of the crankshaft and propeller.

Procedure

Following Procedure is to be followed when a navigational officer calls engine room and says that we have to stop immediately to avoid collision

- When there is an emergency like collision, grounding etc. the controls are transferred immediately in to the Engine room controls

- The bridge will give astern direction in the telegraph, acknowledge the same

- When the telegraph is acknowledged only the starting air cam will reverse its direction but the fuel cam will remain in its running position due to running direction interlock since engine is still running in the ahead direction

- The fuel lever in the engine control room is brought to ‘0’

- As soon as the RPM of the engine drops below 40 % of the Maximum Continuous Rating or MCR rpm of the engine, give break air few times in short time frame

- The break air will inject with astern timing setting inside the ahead moving piston which will resist the piston motion

- Since fuel will not inject until running direction interlock opens, as soon as the rpm drops near to Zero, give fuel and air kick by bringing fuel lever to minimum start setting

- When carrying out Crash Manoeuvring, some safeties need to be bypassed to avoid tripping of engine in mid of emergency

- When the ship stops and situation is under control, a detailed Main engine inspection is to be carried out when there is a chance.

You may also like to read-What are the Essential Requirements for Unattended Machinery Space ?

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

Latest Marine Navigation Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

thank you, very informative post. looking ahead to receive more informative posts at marineinsight.com

Even if I have a slight doubt on a marine topic this place seems like a one stop destination. Thankyou founders and contributors.

Thanks for the motivating words, Ankit. Glad you liked our work.

Sir, i am a junior engineer and would like to know how is crash manoeuvering different from regular manoeuvering? In regular manoeuvering if we are moving ahead do we wait for the engine to stop i.e rpm to be zero and then give astern kick or do we give it right away? Also does engine rpm zero means tht ship speed is also zero or can the ship still move ahead with momentum even if the engine rpm is zero?

Safeties and interlock bypassed during crash manueuvring

What safeties and interlocks are bypassed and do we need to bypass them manually or they will automatically get bypassed by pressing crash manoeuvering button