What are Non Ballast or Ballast Free Ships?

The non ballast or ballast free ships are prototype of a greater paradigm, in accordance with the 1997 International Maritime Organization (IMO) ballast water management Guidelines A.868 (20) and the IMO ballast water convention that approaches ballast operation as the reduction of buoyancy, rather than summing up additional weight to help get the vessel to its required ballast drafts.

Issues with ballast water

Conventional Very large crude carrier (VLCC)’s utilize ballast tanks to obtain a fully submerged propeller and enough forward draft in unloaded transit condition to avoid bottom slamming while reducing bending moments and compensating for trim and heel are also its utilities during cargo operations. But the dire consequences include the coastal organisms that can cause damage when released to foreign ecosystems; and additional fuel for transportation.

The IMO ballast water convention asserts performance criteria to reduce harmful aquatic organisms in ship ballast water and sediments. Hence, it is important to eliminate its use while maintaining transverse stability, bow and propeller submergence, and reducing wind age for adequate manoeuvrability.

Why ballast free ships?

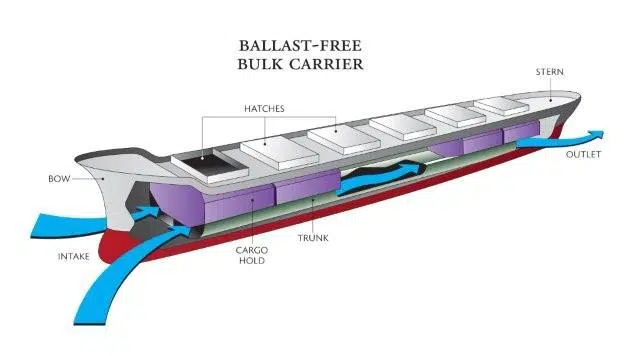

This is one promising design to block hitchhiking organisms and terminate the entire requirements for expensive sterilization equipment like costly filters, ultraviolet irradiation, chemical biocides and other technologies. It creates a constant flow of local seawater through a network of trunks, running from the bow to the stern, below the waterline, thus reducing the potential hauling of contaminated water across the ocean. Plus it could be one giant economic winner by affirming a saving of net capital-cost of about $540,000 per ship.

Features of ballast free ships

- Ballast trunks: Ship ballast tanks are replaced with longitudinal structural ballast trunks consisting of one centre tank, two intermediate tanks and two side tanks which surround the cargo hold below the ballast draft and are connected to an intake plenum and a discharge plenum near the bow and the stern respectively. These ballast trunks are swamped in the ballast circumstance to diminish the ship’s buoyancy.

- Hull Shape: V-shaped hull minimises the resistance and optimises the propeller conditions in fully loaded and unloaded conditions by reducing the weighted sum of the wetted surface. In lightship condition it increases the draft from the normal 3-4 metres (with the bow and propeller almost out of the water) of a conventional 300k DWT VLCC.

- CFD tools: Computational Fluid Dynamics (CFD) compare the syrupy resistance of the new design with that of a more traditional design and assist in maximizing the pressure fields in the bow and stern area.

- Propulsion: The twin screw and optimum diameter propellers allow low draught aft in the unloaded condition and ensure high propulsive efficiency by overlapping propeller arrangement. Propulsion power is estimated on the basis of the resistance and propeller analyses.

- Trim and heel: Longitudinal bulkheads provide with moment equilibrium around the longitudinal centre line for all segregation alternatives and prevent large trims to occur during the cargo operations.

- Cargo segregations: Triality to be loaded in regard to this following segregation share:

Segregation 1: 55%

Segregation 2: 25%

Segregation 3: 20%

Or

Segregation 1: 55%

Segregation 2: 22.5%

Segregation 3: 22.5%

You may also like to read-What is Anti-Heeling System on Ships?

References: dnv, safinah, sciencedaily, marinetalk

Image Credits: boatdesign, dfo-mpo

Do you have info to share with us ? Suggest a correction

Latest Type Of Ships Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

very interesting

See photo of the ballast fee ship CEOBAS.no